The demand for personal cooling solutions is skyrocketing, driven by hotter summers and increased outdoor activities. Sweat-wicking fabrics and traditional cooling methods are hitting their limits, failing to offer sustained, all-day temperature relief. This is where Phase Change Material (PCM) technology steps in, offering a revolutionary passive cooling solution. The unique ability of these materials to intelligently absorb, store, and release heat is transforming not just caps but entire industries.

Phase Change Material (PCM) cooling caps are trending because they address a universal need for effective, hands-free, and long-lasting personal temperature regulation. Unlike active cooling, they require no power or moving parts. The core reason for their rise is their passive, intelligent cooling mechanism: the materials within the cap absorb excess body heat to keep you cool and release stored heat to keep you warm as the environment changes. This “smart” thermal regulation, proven across industries from electronics to construction, is now making its way into wearable gear, perfectly aligning with consumer demand for innovative, functional, and comfortable products.

This trend is far from a gimmick. It’s fueled by a powerful convergence of technological maturity, growing market awareness, and increasing integration into diverse applications. This article will break down the key drivers propelling PCM cooling caps into the spotlight.

How Does PCM Technology Actually Work to Cool You Down?

To understand why PCM cooling caps are effective, we need to look at the science of phase change. PCMs are substances that absorb or release a large amount of latent heat when they change physical state, typically between solid and liquid. This property allows them to act as a dynamic thermal buffer, smoothing out temperature fluctuations.

The magic happens at a specific, pre-programmed temperature. For cooling applications, when your body (or the environment) heats up and reaches the material's melting point, the solid PCM begins to liquefy. During this melting process, it absorbs a significant amount of heat from its surroundings while its own temperature remains nearly constant. This is the cooling phase. Later, when the ambient temperature drops, the liquid PCM solidifies, releasing the stored heat back out. In a cap, this cycle effectively delays and reduces the heat buildup on your head, maintaining a cooler, more comfortable microclimate for an extended period.

What Are the Most Common Types of PCMs Used?

The performance of a PCM cooling product hinges on the specific material used. The main categories are:

- Organic PCMs: These include paraffin waxes and fatty acids. They are chemically stable, non-corrosive, and have a wide range of melting points, making them very popular. For wearable applications, they are often favored for their safety and reliability.

- Inorganic PCMs: These are typically salt hydrates. They offer higher volumetric heat storage and better thermal conductivity than organics but can face issues with stability and corrosion over repeated cycles.

- Bio-based PCMs: A rapidly growing category driven by sustainability trends. These are derived from renewable sources like vegetable oils or animal fats and are gaining traction due to their lower environmental footprint.

For integration into textiles like caps, these materials are almost always microencapsulated. This process involves enclosing microscopic droplets of PCM within a durable polymer shell. This shell prevents the liquid material from leaking, allows it to be seamlessly incorporated into fabric fibers or coatings, and enables it to withstand repeated phase changes without degradation. This technological advancement is key to making wearable PCM products viable.

How Is This Technology Proven in Other Industries?

The credibility of PCMs for cooling caps is bolstered by their proven success in high-stakes, demanding fields. For years, they have been critical components in:

- Electronics Cooling: Managing heat in smartphones, laptops, and servers, where they prevent processors from overheating by absorbing transient thermal loads.

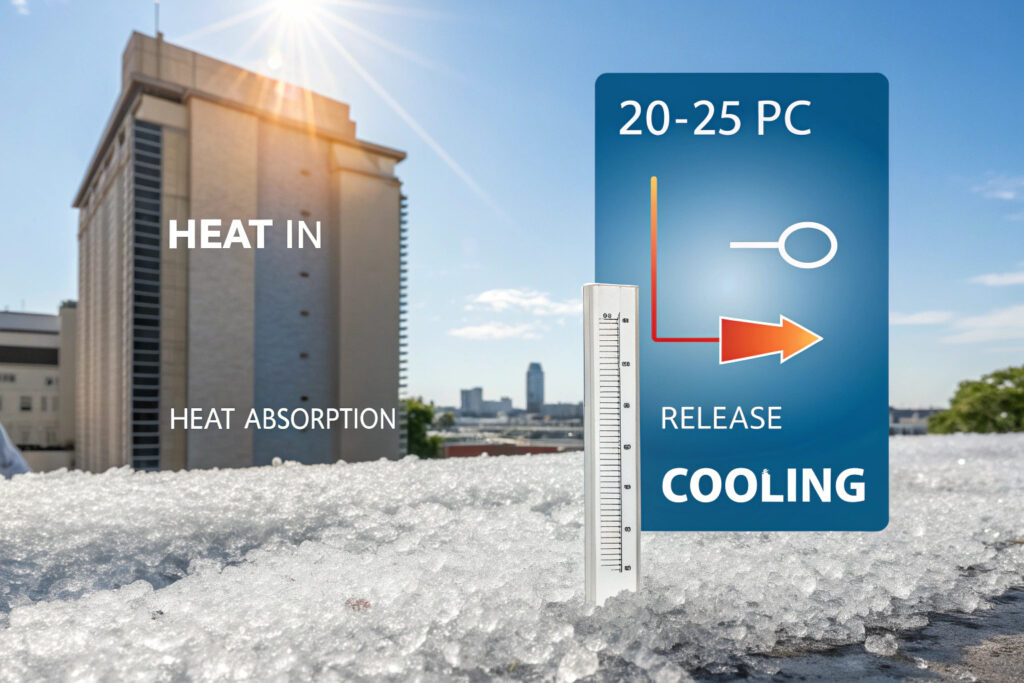

- Building Temperature Regulation: Integrated into walls and ceilings to reduce indoor temperature swings and cut air conditioning energy use by 10-25%.

- Electric Vehicle (EV) Battery Packs: Essential for thermal management, maintaining battery temperature and extending its life and safety.

- Medical/Logistics: Used in cold chain logistics to maintain precise temperatures for vaccines and sensitive pharmaceuticals during transport.

This broad and mature application base demonstrates that PCM technology is a robust, reliable thermal management solution, not just a novelty for consumer goods.

What Market and Consumer Forces Are Driving This Trend?

The rise of PCM cooling caps isn't happening in a vacuum. It's being propelled by a powerful combination of large-scale market growth and specific, evolving consumer demands. The thermal management PCM market itself is on a steep upward trajectory, creating a fertile ecosystem for new applications.

Globally, the market for PCMs in thermal management was valued at approximately $1.47 billion in 2024 and is forecast to grow at a compound annual growth rate (CAGR) of 8.3%, reaching an estimated $3.25 billion by 2034. This growth is fueled by demand across electronics, EVs, and construction. Within this expansion, the textiles and wearables segment is highlighted as an emerging and high-potential application area. As the core technology scales and costs potentially decrease with volume, its adoption in consumer products like clothing and headwear becomes more economically feasible.

What Are the Key Consumer Demand Drivers?

Several converging consumer trends are creating the perfect market for PCM cooling caps:

- Increasingly Hot Climates and Awareness: As heatwaves become more frequent and intense, the need for effective personal cooling solutions grows beyond niche athletic use to general consumer comfort.

- The Outdoor Lifestyle and Fitness Boom: The sustained popularity of hiking, running, cycling, and other outdoor activities has created a large market for gear that enhances performance and comfort in challenging conditions.

- Rise of Functional and Technical Apparel: Consumers, especially in sportswear, are increasingly educated and willing to pay a premium for clothing with proven, innovative technologies that offer tangible benefits.

- Focus on Sustainability and Passive Solutions: There is growing appeal for products that provide comfort without requiring electricity, disposable components (like ice packs), or complex mechanics, aligning with a broader desire for sustainable, low-maintenance solutions.

How Do PCM Caps Compare to Traditional Cooling Methods?

To see their value, it's useful to compare PCM caps to common alternatives:

| Feature | PCM Cooling Cap | Traditional Ventilated Cap | Cooling Towel / Bandana |

|---|---|---|---|

| Cooling Mechanism | Passive, latent heat absorption | Active, evaporative (sweat) & convective | Active, evaporative (water) |

| Duration of Cooling | Long-lasting (hours, until PCM "charges" are depleted) | Intermittent (requires sweat/airflow) | Short-term (10-30 mins, requires re-wetting) |

| Consistency | Provides steady temperature buffering | Highly variable based on activity & humidity | Peaks and fades quickly |

| Maintenance | Recharge by placing in a cool environment; durable | Machine washable | Constant re-wetting needed |

| Key Advantage | Sustained, "set-and-forget" comfort | Breathability, simplicity | Instant, intense initial cool |

This comparison highlights the unique value proposition of PCM caps: they offer proactive, sustained cooling rather than reactive, short-term relief.

What Are the Current Challenges and Future Innovations?

While the potential is significant, the journey from a promising technology to a mainstream wardrobe staple involves overcoming specific hurdles. The current challenges are not necessarily with the core PCM science but with its integration, perception, and optimization for the consumer apparel market.

The primary challenges for PCM cooling caps include managing consumer expectations regarding cooling duration and intensity, ensuring long-term durability and performance consistency after many wash and phase-change cycles, and addressing a potentially higher price point compared to standard caps due to the advanced materials and manufacturing involved. Furthermore, for the technology to gain widespread trust, clear communication about how to properly use and "recharge" the caps (by cooling them down) is essential to prevent perceived performance failures.

What Does the Future Hold for This Technology?

Phase Change Material (PCM) cooling caps are trending because they represent a smart, functional application of a proven thermal management technology to a common human need. Their rise is driven by the material's intrinsic ability to provide sustained, passive cooling, a growing global market that is maturing the technology, and clear consumer demand for innovative solutions to beat the heat. While challenges around cost, durability, and user education remain, ongoing innovations in material science and system design promise a future where intelligent temperature regulation is seamlessly woven into the fabrics of our daily lives. This isn't just a fleeting trend in headwear; it's a glimpse into the future of functional, responsive, and comfortable apparel.

Conclusion

For a forward-thinking headwear manufacturer like Shanghai Fumaoclothing, this trend represents a significant opportunity to move beyond basic fashion and into the high-value domain of functional, technical apparel. By integrating proven PCM technology, you can offer your customers—from outdoor enthusiasts to safety-conscious workers—a tangible performance benefit that commands a premium and builds brand loyalty around innovation. Partnering with an experienced manufacturer ensures that your product overcomes the initial challenges of quality control and cost-effective production.

Ready to integrate cutting-edge thermal comfort into your next headwear line? Understanding the right payment terms and logistics for such a specialized product is key. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can develop and produce your next generation of PCM-enhanced cooling caps.