In industries like hospitality, aviation, healthcare, and corporate events, shared caps—whether for uniforms, safety gear, or promotional gifts—are a practical reality. However, this shared use introduces significant hygiene challenges, primarily the risk of cross-contamination from sweat, skin oils, and microbes. A standard cotton or polyester liner becomes a breeding ground for bacteria, leading to odors, stains, and potential skin irritation for users.

Antibacterial silver fiber liners are crucial for shared caps because they actively inhibit the growth of odor-causing bacteria and fungi directly at the source. This technology transforms a passive piece of headwear into a hygienically active product, ensuring safety, comfort, and durability across multiple users without degradation or unpleasant smells.

Simply put, they are the most effective and durable solution to maintain hygiene in a multi-user environment where frequent washing is impractical or insufficient. While regular liners just absorb sweat, silver-infused liners work to neutralize the problem itself.

How Does Silver Fiber Technology Actually Work?

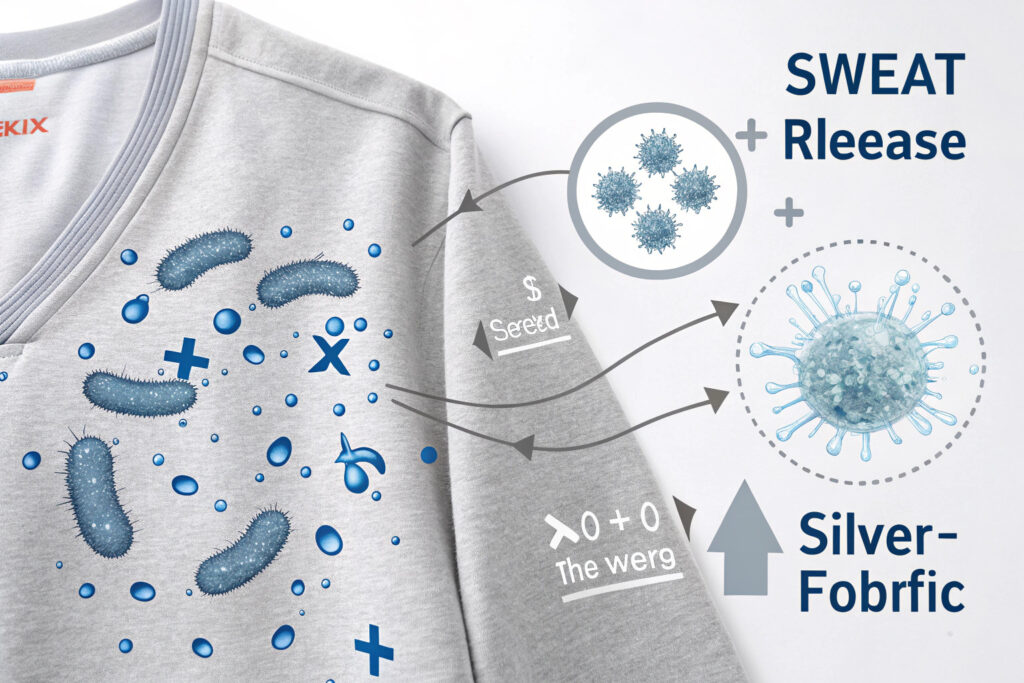

The antibacterial action is not a chemical coating that washes off; it's an intrinsic property of the fiber. During the manufacturing process, pure silver particles are embedded into the polymer matrix of fibers like polyester or nylon before they are spun into yarn. This creates a permanent, homogeneous integration of silver ions throughout the entire fabric.

The mechanism is based on the oligodynamic effect. Minute amounts of silver ions (Ag⁺) are continuously released from the fiber surface when in contact with moisture (like sweat). These positively charged ions are highly reactive and interact with the negatively charged cell walls of bacteria and fungi. They disrupt critical cellular functions: they puncture cell membranes, deactivate respiratory enzymes, and bind to DNA, preventing replication. This halts microbial growth and kills existing cells, effectively stopping the metabolic processes that cause odor and degradation of the fabric.

Why is this superior to topical treatments? Common antibacterial sprays or finishes (like triclosan) are applied to the fabric's surface. They create a temporary layer that diminishes in effectiveness with each wash, sweat exposure, and abrasion. In contrast, silver ions are an integral part of the fiber. Their release is controlled and long-lasting, providing durable efficacy that typically lasts for the functional lifespan of the garment—often cited as 50+ industrial washes without significant reduction in antibacterial performance. For a manufacturer like shanghaifumaoclothing, this means offering a product with a verifiable, long-term value proposition.

What Are the Proven Benefits Beyond Odor Control?

The impact of integrating this liner goes far beyond just fighting smells:

- Enhanced Hygiene & User Safety: It drastically reduces the bioburden (microbial load) on the fabric, minimizing the risk of transmitting common skin bacteria (like Staphylococcus) between users. This is critical in settings like hospitals, kitchens, or anywhere caps are part of a mandatory uniform.

- Preservation of Fabric Integrity: Bacteria and fungi feed on organic matter in sweat, breaking down textile fibers. By inhibiting microbial growth, the silver liner prevents this biodegradation, reducing staining, weakening of fibers, and overall fabric deterioration. Caps last longer and look newer.

- Allergy and Irritation Reduction: For users with sensitive skin or conditions like seborrheic dermatitis, a liner that actively suppresses microbial flora can create a cleaner, less irritating environment against the scalp, improving comfort during extended wear.

- Lower Total Cost of Ownership (TCO): While the initial cost is higher, the extended lifespan of the cap (less frequent replacement), reduced need for aggressive, high-temperature washing (saving energy and water), and maintenance of a professional appearance add significant long-term value for organizations.

Is the Technology Safe and Certified?

Yes, when implemented correctly. Reputable silver fiber suppliers provide materials that are:

- Biocompatible and Non-Toxic: The silver is bound within the fiber, preventing skin absorption at harmful levels. It's widely used in medical textiles like wound dressings.

- Certified: Look for independent lab test reports against international standards like AATCC 100 or ISO 20743, which quantify antibacterial efficacy (e.g., >99.9% reduction against S. aureus and K. pneumoniae).

- Eco-Conscious: Leading silver fiber technologies are designed to minimize silver leaching during washing, addressing environmental concerns. Certifications like OEKO-TEX Standard 100 ensure the final fabric is free from harmful substances.

What Are the Key Design and Sourcing Considerations?

Integrating an antibacterial liner is not just about swapping fabric. It requires thoughtful design and precise sourcing to maximize its benefits and ensure producibility.

The liner should be a dedicated, removable, or easily accessible component. Common designs include:

- Sewn-in Sweatband: A band of silver fabric sewn inside the front brow of the cap, covering the primary sweat area.

- Full-Crown Liner: An entire inner cap made from the antibacterial fabric, offering maximum coverage and protection.

- Removable/Interchangeable Liner: A liner that snaps or hooks in, allowing for separate, more intensive cleaning or replacement when needed—a premium feature for high-use scenarios.

Material selection is paramount. Not all "antibacterial" claims are equal. You must source from established textile mills specializing in yarn-level silver technology (e.g., using branded silver fibers like X-STATIC® or SmartSilver®). Request and verify the mill's antibacterial test reports and material safety data sheets (MSDS). The fabric should also possess good moisture-wicking properties to work in synergy with the silver ions, which require moisture to activate.

Why is partnership with a knowledgeable factory critical? A factory experienced in technical workwear (like shanghaifumaoclothing) will understand how to handle specialty fabrics. They can advise on:

- Comfort: Ensuring the liner is soft and non-irritating.

- Breathability: Pairing it with mesh panels or other breathable structures in the cap body.

- Durability: Using appropriate seam techniques (like flat-lock stitching) to prevent chafing and maintain the liner's integrity.

How Should You Specify the Liner in a Tech Pack?

To avoid ambiguity with suppliers, your tech pack must detail:

- Fiber Specification: E.g., "92% Polyester / 8% Spandex knit with integrated silver ions at the polymer stage. Silver content: ≥ 70 mg/kg of yarn."

- Performance Standard: E.g., "Fabric must provide >99% antibacterial activity against Staphylococcus aureus and Escherichia coli as per AATCC 100 method after 50 industrial washes."

- Physical Properties: Weight (GSM), color, stretch percentage, and required certifications (OEKO-TEX, etc.).

- Construction: Exact dimensions, placement in the cap, and seam specification.

What Are the Common Pitfalls to Avoid?

- False Economy: Choosing a fabric with a cheap silver coating or spray-on finish. It will lose effectiveness quickly and may wash off, discoloring the cap.

- Poor Integration: Designing a liner that creates a "plastic bag" effect, trapping heat and moisture. The antibacterial action works with moisture, but user comfort requires breathability.

- Lack of Verification: Not testing final production samples independently. Always conduct a verification test on a finished cap to ensure the promised efficacy is present in the final product.

How Does This Impact Washing Protocols and Lifespan?

The presence of an antibacterial liner fundamentally changes the care regimen for shared caps, moving the focus from frequent sanitation to effective maintenance.

While the liner continuously fights microbes, regular cleaning is still essential to remove salt crystals, skin cells, and grease that can physically block the fiber surface and reduce ion release efficacy. However, the washing can be less aggressive.

Recommended washing protocols for silver-lined caps:

- Lower Temperature Washes: Effective cleaning can often be achieved at 30°C-40°C (86°F-104°F), reducing energy consumption and fabric stress compared to the high-temperature washes often needed for non-treated fabrics.

- Milder Detergents: Avoid bleach (chlorine) and strong alkaline detergents, as they can corrode the silver particles over time. Use neutral pH detergents.

- Air Drying: Preferred over tumble drying on high heat, which can degrade elastic components and, over time, potentially affect the fiber matrix.

How does this extend the cap's functional lifespan? The combined effect is powerful. By preventing the microbial decay of fibers and allowing for gentler cleaning, the cap's fabric, color, and structure are preserved for much longer. A shared cap that might need replacement every 6-12 months could now last 2-3 years or more, representing a direct and calculable return on investment for the purchasing organization.

What is the Total Cost of Ownership (TCO) Analysis?

When procuring shared caps, the initial unit price is only part of the story. A simple TCO analysis should include:

- Purchase Price: Higher for silver-lined caps.

- Replacement Frequency: Significantly lower for silver-lined caps.

- Cleaning Costs: Lower water temperature and potentially fewer wash cycles for silver-lined caps.

- Hygiene/Safety Incidents: Potentially reduced risk, though hard to quantify.

In most commercial shared-use scenarios, the higher upfront cost is offset within the first 12-18 months by reduced replacement rates, making it a financially sound decision.

How to Communicate This Value to Buyers?

Your marketing and sales materials must educate B2B buyers. Don't just say "antibacterial." Explain:

- The Problem: Cross-contamination, rapid odor, short lifespan.

- The Science: Durable, yarn-based silver ion technology.

- The Benefits: User safety, professional image, lower long-term costs.

- The Proof: Independent lab test certificates.

Conclusion

Antibacterial silver fiber liners are not a luxury add-on for shared caps; they are a critical hygiene and operational upgrade. They solve the fundamental problem of multi-user headwear by providing continuous, durable protection against microbes where it matters most. This technology directly enhances user safety, extends product lifespan, reduces maintenance costs, and protects the professional image of an organization.

For any business or institution implementing a uniform or shared cap program, specifying caps with integrated silver fiber liners is a proactive step toward higher standards of hygiene and value. If you are looking to source or develop such specialized headwear for your organization, I recommend contacting the team at Shanghai Fumao Clothing. You can discuss technical specifications and procurement options with their Business Director, Elaine, at elaine@fumaoclothing.com.