Arctic research subjects personnel and equipment to one of the planet's most extreme environments: temperatures plunging far below zero, relentless wind chill, and the constant risk of moisture from both precipitation and perspiration. Standard winter gear often fails under these conditions, becoming heavy, cumbersome, and ineffective when wet. The traditional Russian ushanka, with its iconic ear flaps and fur lining, provides a proven base design for extreme cold. However, by integrating modern aerogel insulation, this classic hat is transformed into a pinnacle piece of performance gear ideally suited for the scientific rigors of the Arctic.

Aerogel-insulated ushankas are ideal for Arctic research because they combine unmatched lightweight warmth (superior thermal resistance with minimal weight) with critical moisture management, windproof integrity, and long-term durability—all essential for maintaining researcher safety, comfort, and focus during extended operations in the field.

This guide breaks down the advanced material science behind aerogel and explains how its properties specifically solve the unique challenges faced by Arctic research teams. Learn moreshanghaifumaoclothing detials page.

What Makes Aerogel a "Super-Insulating" Material?

To understand why aerogel is revolutionary, one must first understand the principles of heat transfer. Insulation works by trapping still air, a poor conductor of heat. Aerogel, often called "frozen smoke," excels at this like no other material due to its nanostructure.

How does aerogel's structure create such high performance?

Aerogel is a solid material derived from a gel, where the liquid component has been replaced with gas. This results in a structure that is over 90% air. However, this air is trapped within a vast, nanoporous silica network. These pores are incredibly small—on the scale of nanometers—which severely restricts the movement of air molecules. This drastically reduces all three methods of heat transfer:

- Conduction: The solid silica matrix is tenuous and tortuous, hindering heat flow through the solid material.

- Convection: The nanopores are too small for air to circulate effectively, eliminating convective heat loss.

- Radiation: Special formulations can include opacifiers to scatter infrared radiation.

The result is a material with the lowest thermal conductivity of any solid, typically around 0.015 W/m·K. This means it provides the same insulation as a much thicker layer of conventional foam or down, allowing for thinner, less bulky hat designs without compromising warmth.

What are the key physical properties of aerogel?

Beyond its insulating power, aerogel boasts other properties critical for field gear:

- Extremely Lightweight: It adds almost negligible weight to the ushanka, reducing neck strain and fatigue during long wear.

- Hydrophobic: High-quality silica aerogels are inherently water-repellent. They will not absorb liquid water or water vapor, ensuring the insulation does not become waterlogged and lose its thermal resistance.

- Durable and Incompressible: Unlike down or some synthetic fills, aerogel does not permanently compress or lose its loft over time. Its performance remains consistent for the lifespan of the product.

How Do Aerogel-Ushankas Solve Specific Arctic Field Problems?

The theoretical advantages of aerogel translate directly into practical benefits that address the daily hardships of Arctic research.

How does it manage moisture from both inside and out?

Arctic conditions present a dual moisture threat: external (snow, sleet) and internal (sweat from exertion). A wet insulator is a failed insulator.

- External Moisture: The hydrophobic nature of aerogel means that snowmelt or sleet will not penetrate the insulating layer. It keeps the thermal core dry. This is a significant advantage over down, which clumps and loses insulation when wet, and even over some synthetics that can absorb moisture over time.

- Internal Moisture (Perspiration): Researchers are active. An effective hat must allow sweat vapor to escape to prevent condensation inside, which can lead to chilling. A well-designed aerogel ushanka will pair the insulation with a breathable, moisture-wicking inner lining (like a merino wool blend) to move vapor away from the head before it can condense and freeze.

Why is weight-to-warmth ratio so crucial for researchers?

Every gram counts in field logistics, and researcher fatigue is a real safety concern. An aerogel-insulated ushanka can provide the warmth of a much heavier traditional hat. This reduces physical load, minimizes heat buildup during moderate activity, and allows for greater comfort and extended wearability. This aligns with the ergonomic principles used in designing other critical field gear, such as high-performance, packable hats for mobile professionals.

What Does a Modern Aerogel Ushanka Design Entail?

Integrating aerogel requires thoughtful design to maximize its benefits while maintaining the ushanka's functional heritage.

What are the essential design features?

A best-in-class aerogel ushanka would incorporate:

- Strategic Aerogel Placement: Using aerogel as a thin, continuous panel across the crown and around the ears, targeting areas of greatest heat loss, rather than stuffing the entire hat.

- Windproof and Water-Resistant Outer Shell: A high-tenacity nylon or polyester shell with a durable water repellent (DWR) finish to block wind and shed snow.

- Moisture-Managing Interior: A soft, breathable lining that wicks sweat. The ear flaps might retain a soft, natural fur or high-pile synthetic fur trim for comfort around the face and to prevent frostbite on the cheeks.

- Secure, Adjustable Fit: Essential in high winds. This includes a reliable chin strap and adjustable headband to seal out drafts.

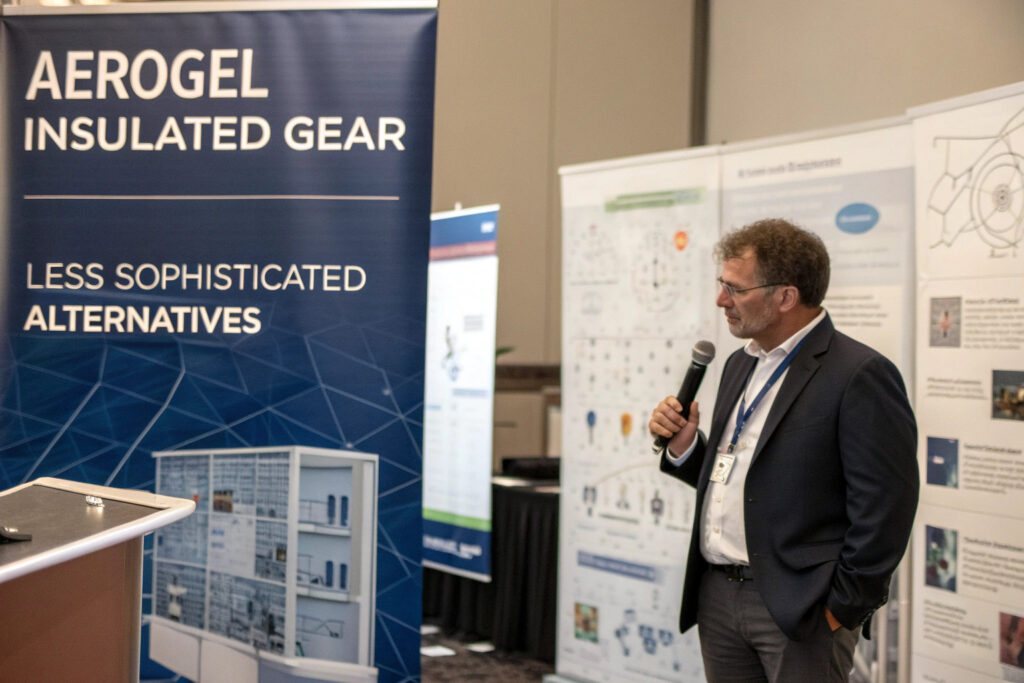

How does it compare to traditional insulation?

This table clarifies the advantages:

| Insulation Type | Warmth/Weight Ratio | Performance When Wet | Long-Term Loft & Durability | Bulk/Profile |

|---|---|---|---|---|

| Aerogel | Exceptional (Best-in-class) | Unaffected (Hydrophobic) | Excellent (Does not compress) | Very Low (Thin) |

| Down (High-Fill) | Excellent | Poor (Clumps, loses loft) | Good (Can clump over time) | Medium |

| Synthetic Fill (e.g., PrimaLoft®) | Good | Good (Retains some warmth wet) | Fair (Can degrade with compression) | Medium-High |

What Are the Considerations for Production and Adoption?

While superior, aerogel-insulated gear faces hurdles related to cost and manufacturing that must be navigated.

What are the main barriers to widespread use?

The primary barrier is cost. Aerogel is a high-tech material with a complex manufacturing process, making it significantly more expensive per unit than standard insulations. This makes it suited for professional, military, or high-end expedition gear where performance is paramount and budgets are higher. Manufacturing also requires specialized knowledge to handle the brittle nature of traditional aerogel blankets, though newer, more flexible composite forms are easing integration.

What is the future of aerogel in extreme cold gear?

As production scales and costs gradually decrease, aerogel is poised to move from niche applications to broader adoption. For Arctic research institutions, outfitting teams with such gear is an investment in safety, productivity, and morale. The demonstrable advantages in maintaining core temperature, managing moisture, and reducing fatigue directly support successful scientific outcomes. It represents the same commitment to technical innovation as seen in other fields, like employing blockchain for ultimate material traceability in supply chains.

Conclusion

Aerogel-insulated ushankas represent the confluence of timeless design and cutting-edge material science. By offering unparalleled warmth without weight, maintaining performance in wet conditions, and providing durable, long-lasting insulation, they directly answer the severe environmental challenges of Arctic research. For scientists working at the edge of human endurance, this technology is not a luxury but a critical tool that enhances safety, comfort, and operational capability in the world's coldest laboratory.

For brands and organizations aiming to develop or procure the most advanced cold-weather gear for professional use, partnering with a manufacturer skilled in technical material integration is essential. If you are interested in exploring the development of aerogel-insulated headwear or other extreme-environment apparel, please contact our Business Director Elaine at elaine@fumaoclothing.com to discuss how we can engineer solutions for the most demanding conditions.