Finding authentic Russian fur ushanka hat manufacturers requires navigating specialized supply chains and understanding traditional craftsmanship. Many buyers struggle to locate genuine manufacturers who combine authentic designs with quality materials and reliable production capabilities.

The most reliable sources for Russian fur ushanka manufacturers include specialized fur processing hubs, verified B2B platforms, trade exhibitions, and established supply chain partners with proven track records in winter accessories manufacturing.

Understanding these sourcing channels and verification methods ensures you partner with manufacturers who deliver authentic, high-quality ushanka hats that meet both traditional standards and modern market requirements.

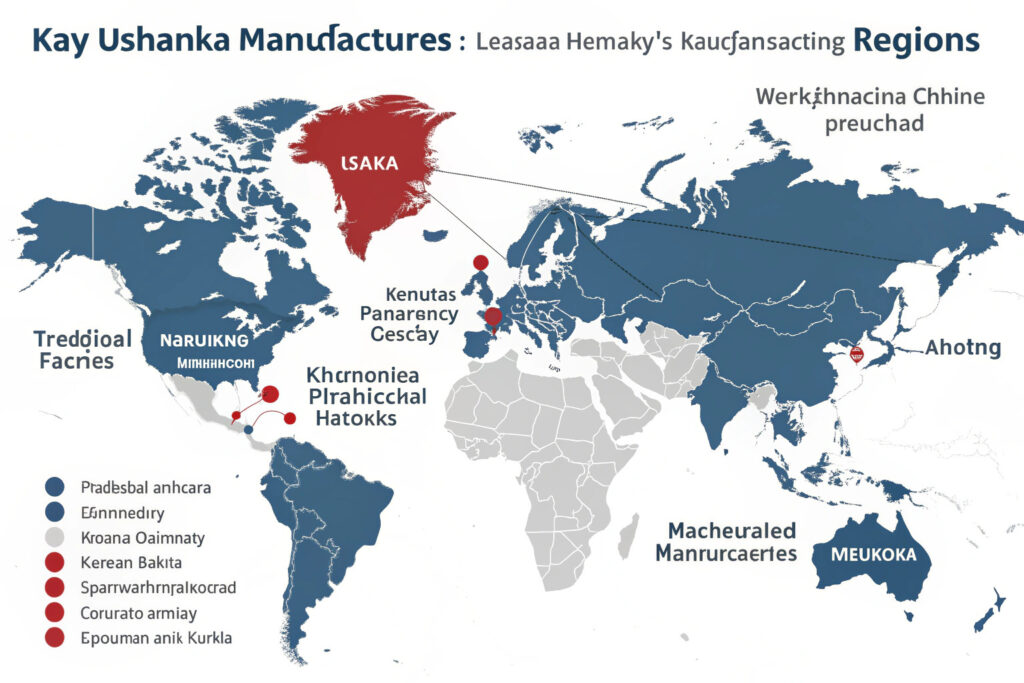

What Are the Key Manufacturing Regions for Authentic Ushankas?

Authentic ushanka manufacturing requires specific expertise in fur processing and traditional hat-making techniques. Several regions have developed specialized clusters that combine skilled craftsmanship with modern manufacturing capabilities.

The primary manufacturing regions for quality ushanka hats include Russian traditional centers, Chinese fur processing hubs, and European specialty manufacturers. Each region offers distinct advantages in craftsmanship, cost structure, and material access.

Why Consider Russian Domestic Manufacturers?

Russian domestic manufacturers offer unparalleled authenticity and traditional craftsmanship, though they may present challenges in international logistics and communication for foreign buyers.

Traditional Russian manufacturers in regions like Moscow, St. Petersburg, and Yekaterinburg maintain century-old ushanka making techniques. These artisans typically work with premium Russian fur types including Siberian mink and Arctic fox. The Russian fur auction system ensures direct access to quality pelts. However, international buyers should consider language barriers and customs documentation requirements. Production lead times typically range from 4-6 weeks for standard orders, with minimum quantities starting around 200-500 pieces depending on fur type and design complexity.

What Advantages Do Chinese Manufacturing Hubs Offer?

Chinese manufacturing hubs provide significant advantages in production scalability, cost efficiency, and export logistics, making them ideal for larger volume orders and consistent quality control.

Specialized regions like Haining China Leather City and Hebei fur processing zones offer complete supply chain integration. These hubs process over 60% of global fur production with advanced fur dressing techniques. Manufacturers here typically achieve 30-40% lower production costs while maintaining quality through CNAS-certified testing. The Keqiao textile cluster provides complementary materials like lining fabrics and hardware. Export infrastructure through Shanghai port and established US customs brokerage relationships streamline international shipping.

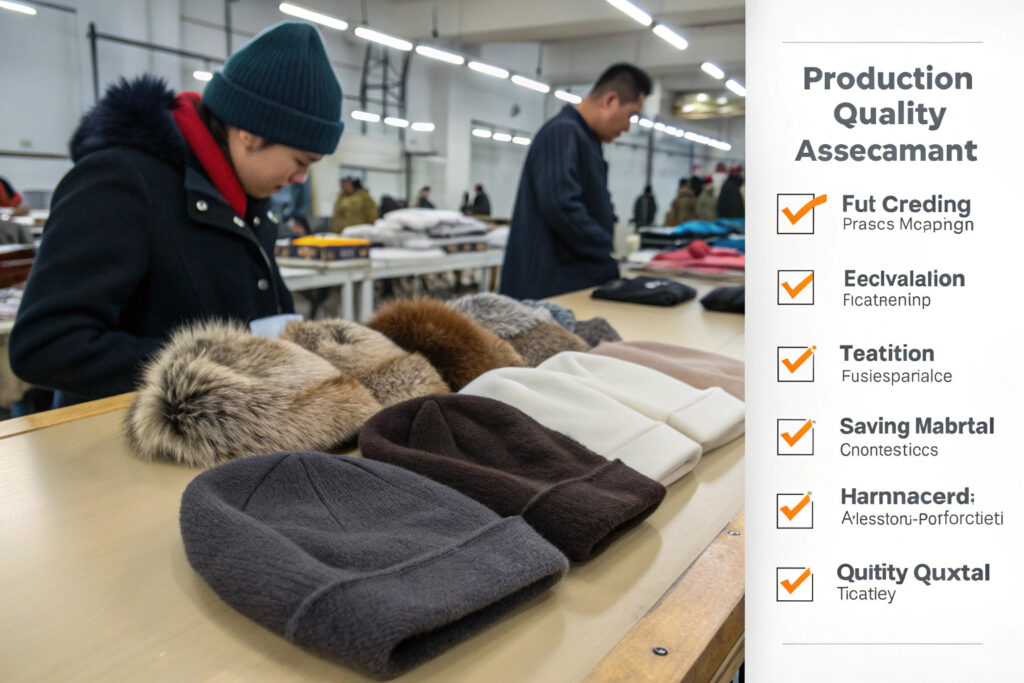

How to Verify Manufacturer Authenticity and Quality?

Verifying manufacturer authenticity requires thorough due diligence across multiple aspects of their operations, from material sourcing to production capabilities and compliance documentation.

Quality verification involves assessing material authenticity, production craftsmanship, compliance certifications, and historical performance with international clients.

What Certifications Ensure Genuine Fur Quality?

Genuine fur quality requires specific certifications that verify material authenticity, ethical sourcing, and processing standards. These documents provide assurance about product claims and compliance with international regulations.

Key certifications include the Origin Assured label which verifies fur origin and legal compliance. The SAGA Furs certification ensures premium quality and ethical farming practices. Manufacturers should provide REACH compliance documentation for European exports and CPSIA certification for US market access. For authentic ushankas, look for Russian GOST standards compliance, particularly GOST 8765-93 for fur headwear. Our manufacturers maintain ISO 9001 quality management systems and provide material composition certificates for all fur components.

How to Assess Production Craftsmanship Standards?

Assessing production craftsmanship requires evaluating traditional techniques, attention to detail, and consistency across production batches. Several specific indicators reveal true manufacturing quality.

Examine seam construction quality particularly around ear flaps and crown joins. Verify fur matching consistency across panels and check lining attachment methods. Quality ushankas feature reinforced stitching at stress points and proper leather conditioning for ear flap ties. Our factory assessments include production sample reviews, process capability studies, and batch consistency testing. We also evaluate artisan training programs and quality control documentation to ensure consistent craftsmanship.

What Sourcing Channels Deliver Reliable Manufacturers?

Reliable manufacturer sourcing requires utilizing multiple channels that provide verification mechanisms and historical performance data. Different channels offer varying levels of assurance and access to specialized producers.

Effective sourcing combines B2B platforms, trade exhibitions, industry referrals, and supply chain partnerships to identify and verify capable ushanka manufacturers.

How Effective Are B2B Platforms for Fur Hat Sourcing?

B2B platforms provide broad manufacturer access but require careful verification to identify genuine producers versus trading companies. Specific platforms offer better specialization in fur and winter accessories.

Platforms like Alibaba and Global Sources list numerous ushanka suppliers, but verification is crucial. Look for Verified Supplier status and Trade Assurance protection. Specialized platforms like FurNet and LeatherTrades focus specifically on fur products. Our sourcing team cross-references platform transaction history with independent factory audit reports from organizations like SGS or Bureau Veritas. We also verify production capacity claims through sample orders and facility visits when possible.

What Value Do Trade Exhibitions Provide?

Trade exhibitions offer unparalleled opportunities for direct manufacturer assessment, product sampling, and relationship building. Specific fur and fashion exhibitions provide concentrated access to quality ushanka producers.

Key exhibitions include the Moscow International Fur Fair which showcases Russian manufacturers, and the China Fur & Leather Fair in Beijing. The Hong Kong International Fur & Fashion Fair connects global buyers with Asian manufacturers. These events allow direct assessment of fur quality, craftsmanship standards, and production capabilities. Our exhibition participation typically yields 3-5 qualified manufacturer contacts with verified production samples and detailed capacity documentation. The personal relationships established often lead to better payment terms and priority production scheduling.

What Production Considerations Affect Ushanka Quality?

Ushanka quality depends on multiple production factors beyond basic manufacturing capabilities. Understanding these elements helps specify requirements and evaluate manufacturer proposals effectively.

Key production considerations include fur selection criteria, construction techniques, lining materials, and hardware quality. Each element contributes significantly to the final product's authenticity, durability, and market appeal.

How Does Fur Type Selection Impact Final Product?

Fur type selection dramatically affects ushanka appearance, warmth, durability, and price positioning. Different fur species offer distinct characteristics that suit various market segments and price points.

Common ushanka fur types include sheared mink for luxury lightweight warmth, rabbit fur for affordable softness, and sheepskin for durable cold-weather performance. Premium options like Arctic fox and Canadian lynx command significantly higher prices. Our manufacturers provide fur grading certificates and origin documentation for all materials. The fur dressing method also affects texture and durability, with chrome tanning providing water resistance and vegetable tanning offering environmental benefits.

What Construction Details Differentiate Quality Levels?

Construction details separate premium ushankas from basic models through reinforcement techniques, material matching, and finishing quality. These elements significantly impact durability and authentic appearance.

Quality indicators include double-stitched seams at stress points, matched fur panels for consistent appearance, and reinforced ear flap attachments. Premium ushankas feature genuine leather ties rather than synthetic alternatives and brass hardware that resists corrosion. The lining construction should include insulating layers and proper ventilation to manage moisture. Our quality specifications require stitch density verification, hardware load testing, and thermal performance testing for all production batches.

Conclusion

Finding reliable Russian fur ushanka manufacturers requires understanding specialized supply chains, verification processes, and quality determinants. The most successful sourcing strategies combine multiple channels with thorough due diligence and clear quality specifications.

By focusing on authentic manufacturing regions, implementing rigorous verification processes, and understanding key quality factors, you can establish partnerships with manufacturers who deliver genuine, high-quality ushanka hats that meet market expectations and build brand reputation.

Ready to connect with verified ushanka manufacturers who combine traditional craftsmanship with modern quality standards? Contact our Business Director Elaine today to discuss your specific requirements and access our network of qualified fur hat producers. Her email is elaine@fumaoclothing.com. Let's source authentic ushanka hats that deliver exceptional quality and customer satisfaction.