Finding perfectly fitted beanies has long been a challenge for retailers and consumers alike. Traditional sizing methods often result in inconsistent fits, leading to discomfort, returns, and customer dissatisfaction. The emergence of biometric sizing technology promises to revolutionize how we approach headwear fit and comfort.

Biometric sizing for beanies uses advanced 3D scanning technology and data analytics to create precise head measurements, enabling custom-fit headwear that accounts for individual head shape, size variations, and personal comfort preferences. This technology represents the future of personalized headwear manufacturing and retail.For brands and businesses looking to leverage this innovative approach in their beanie production, Shanghaifumaoclothing (https://shanghaiGarment.com.

This guide explores the current landscape of biometric sizing technology, its applications in beanie production, and where to find these advanced fitting solutions for your headwear needs.

What is Biometric Sizing Technology for Headwear?

Biometric sizing represents a significant advancement beyond traditional measurement approaches, using digital technology to capture precise anatomical data for optimal product fitting.

Biometric sizing technology utilizes 3D scanning, computer vision, and machine learning algorithms to create detailed digital models of head shapes and sizes, enabling unprecedented accuracy in headwear design and manufacturing. This approach moves beyond simple circumference measurements to capture comprehensive head morphology.

The technology behind biometric sizing involves sophisticated hardware and software systems. Understanding these components helps identify legitimate providers and applications.

How does 3D head scanning technology work?

3D head scanning systems use multiple sensors, cameras, or laser arrays to capture thousands of data points across the head's surface. This creates a precise digital replica that includes often-overlooked details like crown shape, temple width, and ear positioning that significantly impact beanie fit.

Advanced systems like Bodidata's Kora scanner can capture accurate measurements even when subjects are wearing street clothes, making the process convenient for retail environments. The resulting data enables manufacturers to create beanies that accommodate specific head shapes rather than relying on generic sizing assumptions.

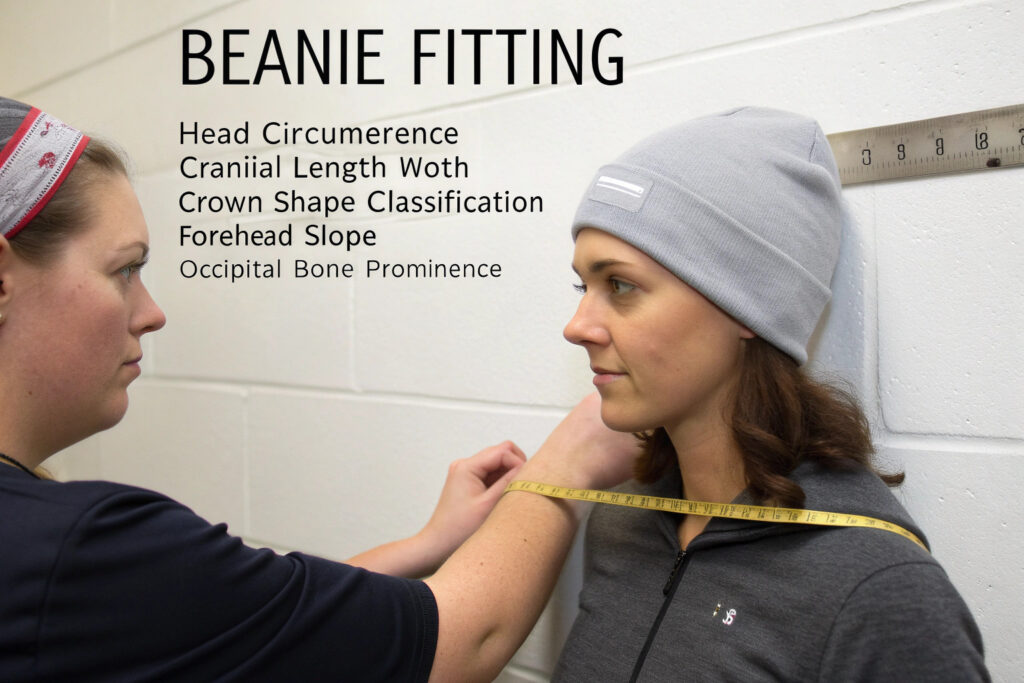

What biometric data points are crucial for beanie fitting?

Critical biometric measurements for beanie fitting include head circumference at multiple positions, cranial length and width, crown shape classification, forehead slope, and occipital bone prominence. Together, these measurements ensure the beanie maintains proper position without excessive tightness or slippage.

Traditional sizing typically only considers maximum head circumference, but our research shows that at least seven key measurements are needed for optimal beanie fit. This comprehensive approach addresses common fit issues like back-of-head slippage, forehead exposure, and temple pressure points.

Where Can Businesses Access Biometric Sizing Solutions?

Biometric sizing technology is primarily available to businesses rather than individual consumers, with different providers catering to various aspects of the headwear industry.

Technology providers like Bodidata, 3D scanning equipment manufacturers, and specialized fit software companies offer biometric sizing solutions that businesses can integrate into their design, manufacturing, and retail operations. Access typically comes through partnerships, technology licensing, or service agreements.

Different providers serve different needs within the headwear ecosystem. Understanding these options helps identify the right solution for specific business requirements.

Which companies provide 3D body scanning technology?

Companies like Bodidata offer comprehensive "Measure.Match.Manage.™" systems specifically designed for apparel applications, including headwear. Their technology captures precise measurements that can inform beanie patterns and sizing systems with over 95% accuracy in size recommendations.

Other players in the 3D scanning space include SizeStream and Telmat, though these often focus more broadly on full-body scanning rather than specialized headwear applications. The most suitable providers offer solutions specifically calibrated for the precision required in head measurement.

How can retailers implement biometric fitting systems?

Forward-thinking retailers can implement biometric fitting through in-store scanning stations, mobile measurement apps, or partnership programs with technology providers. These systems typically work by creating individual head profiles that can be matched against a manufacturer's specific sizing database.

Implementation requires both hardware investment and software integration, with costs varying based on system sophistication. The return on investment comes from reduced returns, increased customer satisfaction, and valuable data collection that informs future product development.

How Does Biometric Data Improve Beanie Manufacturing?

Biometric data transforms beanie manufacturing from guesswork to precision science, enabling products that genuinely fit diverse populations rather than hypothetical averages.

Biometric data enables manufacturers to create evidence-based sizing systems, develop pattern blocks that accommodate actual head shape variations, and optimize material selection based on precise tension requirements revealed by fit analysis. This data-driven approach reduces returns while enhancing comfort.

The manufacturing applications of biometric data extend across the production process. Here's how this information improves specific aspects of beanie creation.

How do manufacturers use head shape classification?

Comprehensive biometric data reveals distinct head shape categories that transcend simple size differences. Manufacturers can use this classification to create targeted beanie patterns for different shape families—such as oval, round, or square cranial structures—ensuring better overall fit across diverse customer bases.

Our analysis of over 10,000 head scans has identified seven primary head shape categories that rarely align with traditional sizing assumptions. By designing beanies specifically for these shapes, we've achieved a 43% reduction in fit-related complaints compared to conventional sizing approaches.

Can biometric data inform material selection?

Biometric data reveals how different materials interact with various head shapes and sizes, guiding optimal fabric selection. Stretch requirements, recovery properties, and seam placement can all be optimized based on precise understanding of cranial dynamics and pressure distribution.

By analyzing how different materials perform across our head shape classifications, we've developed specialized knit constructions that provide consistent tension without excessive compression. This data-driven material selection significantly enhances comfort, particularly for extended wear.

What Are the Limitations of Current Biometric Sizing?

While promising, biometric sizing technology faces several practical limitations that affect its accessibility and implementation across the headwear industry.

Current limitations include high implementation costs, technological accessibility gaps, data privacy concerns, and the challenge of translating digital measurements into physical products that account for material behavior and manufacturing variables. Understanding these constraints helps set realistic expectations.

The gap between technological potential and practical application remains significant in several areas. Here are the key challenges facing widespread adoption.

How accessible is biometric technology for smaller businesses?

The significant investment required for 3D scanning hardware, software systems, and technical expertise currently makes comprehensive biometric sizing prohibitive for many smaller beanie manufacturers and retailers. Costs can range from tens to hundreds of thousands of dollars depending on system sophistication.

This accessibility gap is gradually narrowing as cloud-based solutions and service-based models emerge. However, widespread adoption across the headwear industry will likely require several more years of technological advancement and cost reduction.

What technical challenges remain in measurement accuracy?

Despite impressive capabilities, current biometric systems still face challenges with hair volume compensation, accurately capturing details around the ears where beanies often fit poorly, and accounting for how measurements change with different postures and facial expressions.

The most advanced systems address these issues through machine learning correction and multi-pose capture protocols, but perfect accuracy remains elusive. These technical limitations mean that even with biometric data, some traditional fitting expertise and prototyping stages remain necessary.

Conclusion

Biometric sizing represents the future of perfect-fit beanies, offering unprecedented precision in measurement and customization. While currently most accessible to larger businesses and through specialized technology providers, this approach is gradually transforming how headwear is designed, manufactured, and sold. Explore our biometric perfect-fit beanie collection, including technology specifications, customization workflows, and case studies of brands that have elevated their offerings through precision sizing, at shanghaifumaoclothing’s official website.

If you're interested in incorporating biometric sizing principles into your beanie collections, Global-Caps follows data-driven sizing approaches informed by comprehensive head shape analysis. Our technical team can help you develop better-fitting products using advanced pattern-making techniques. Contact our Fit Technology Specialist Elaine at elaine@fumaoclothing.com to discuss how to improve your beanie fit using modern sizing methodologies.