As a buyer for a major fashion brand or a startup founder launching a new line, you know the traditional sampling process is a huge bottleneck. You wait weeks, sometimes months, for a physical sample to arrive from overseas, only to find the color is slightly off or the logo placement isn't quite right. This slow, expensive, back-and-forth process burns through your budget, delays your launch, and stifles your creativity.

The solution is to leverage AI-powered virtual sampling, a revolutionary technology that generates photorealistic 3D models of your hat designs in minutes. By using specialized software and partnering with a tech-forward manufacturer, you can visualize different materials, colors, and logo placements instantly, allowing you to make critical design decisions, secure internal approvals, and finalize your product line before a single physical sample is ever produced.

I've been in the hat manufacturing industry for over two decades, and I've never seen a technology with more potential to transform how we work with our clients. At my company, Shanghai Fumao Clothing, we are embracing this shift. AI virtual sampling isn't about replacing physical samples entirely; it's about making the entire product development cycle faster, cheaper, and more collaborative. It's about turning your creative vision into a tangible, manufacturable product with unprecedented speed.

Why Is Virtual Sampling a Game-Changer for Hat Development?

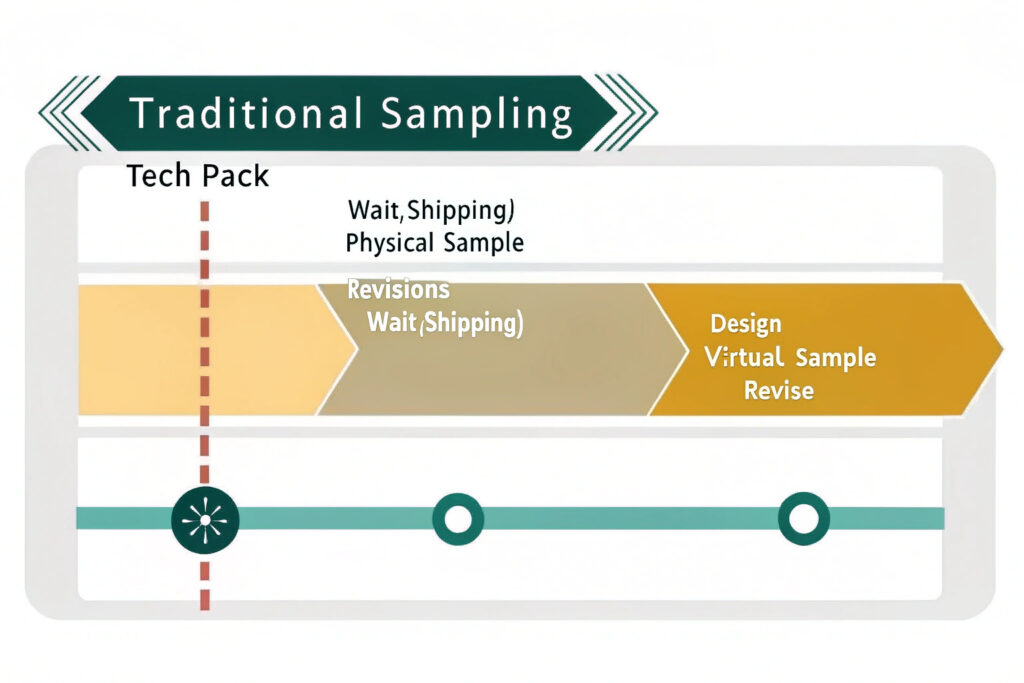

You're used to the old way: you send a tech pack, wait for a lab dip, then wait for a physical sample. The entire process is linear, slow, and opaque. You're essentially designing in the dark, making educated guesses about how a 2D design will translate to a 3D product.

AI virtual sampling shatters this old model. It provides a dynamic, interactive, and incredibly fast alternative. Instead of waiting for a package, you get a link. Instead of a single static sample, you get a fully manipulable 3D model that you can view from any angle, under different lighting conditions. This fundamentally changes the creative process from one of "wait and see" to one of "design and decide" in real-time.

Let's dive into the specific, game-changing advantages that make this technology an essential tool for any modern apparel brand.

How Does It Drastically Reduce Lead Times?

The single biggest advantage is speed. A traditional physical sample can take 2-4 weeks to produce and ship. If it requires a revision, you're looking at another 2-4 weeks. With AI virtual sampling, a 3D model can be generated in a matter of hours, sometimes minutes. You can review the design, request changes (e.g., "make the logo 10% larger," "change the stitching color to red"), and see the updated virtual sample almost instantly. This allows you to finalize 95% of your design decisions in a single afternoon, reducing your pre-production timeline from months to days. This is a core principle of agile product development applied to fashion.

How Does It Cut Development Costs?

Physical samples are expensive. Each one requires materials, labor, and costly international express shipping. A single sample can cost anywhere from $50 to $200. When you go through multiple rounds of revisions, these costs add up quickly. Virtual sampling eliminates the need for most of these early-stage physical samples. You only move to a final, "golden sample" for physical confirmation once you are completely satisfied with the design in its virtual form. This can reduce your sample development budget by over 70%, freeing up capital to invest in marketing or expanding your product line.

How Does the AI Virtual Sampling Process Actually Work?

You might be imagining a complex process that requires you to be a 3D modeling expert. The reality is much simpler, especially when working with a capable manufacturing partner. The process is designed to be intuitive for designers and product managers.

The process begins with your design input, which can be as simple as a 2D sketch or a standard tech pack. Your manufacturing partner then uses specialized 3D apparel design software to create a digital "twin" of the hat. This is where the AI comes in: the software uses advanced algorithms to simulate how different fabrics will drape, how colors will appear under light, and how a logo will conform to the curved surface of the hat. The result is a photorealistic, interactive 3D model.

What Is the Role of 3D Design Software?

The magic happens inside powerful software platforms like CLO 3D and Browzwear. These are the industry standards for virtual apparel design. A skilled 3D technician at our company, Shanghai Fumao Clothing, takes your 2D pattern from the tech pack and digitally "sews" it together in the software. They then apply digital versions of real-world fabrics. These aren't just simple textures; they are digital materials with programmed properties for weight, drape, and stiffness, ensuring the virtual hat behaves just like a real one. This technology is a direct application of digital twin concepts to the fashion industry.

How Do You Review and Approve the Virtual Sample?

Once the 3D model is created, we share it with you via a web-based viewer. You don't need any special software to see it. You can open the link in your browser and use your mouse to rotate the hat 360 degrees, zoom in on stitching details, and even view it on a virtual avatar to check the fit and proportions. The platform allows you to leave comments and annotations directly on the 3D model (e.g., "Check this seam," "Is this logo centered?"). This creates a clear, visual feedback loop that eliminates the miscommunication common with email chains and static PDFs.

What Are the Limitations and When Is a Physical Sample Still Needed?

While virtual sampling is a powerful tool, it's important to have realistic expectations. It is not a complete replacement for physical reality, but rather a powerful supplement to it. Understanding its limitations is key to using it effectively.

The primary limitation is the inability to replicate the tactile experience. You can't feel the "hand" of the fabric, the weight of the hat, or the physical quality of the construction through a screen. For this reason, a final physical sample is still a crucial step before committing to a bulk production run of thousands of units.

Why Can't Virtual Sampling Replicate "Hand-Feel"?

"Hand-feel" is the term we use to describe the tactile qualities of a fabric—its softness, texture, and weight. While 3D software is incredibly advanced at visualizing appearance, it cannot yet simulate the complex sensory feedback of touch. You need to physically hold the hat to truly judge if the fabric meets your brand's quality standards. This is especially important for products where comfort is paramount, like a soft beanie or a performance running cap. This sensory gap is a major focus of ongoing R&D in haptic technology.

What Is the Role of the "Golden Sample"?

The "Golden Sample" or "Pre-Production Sample" (PPS) is the final physical sample you approve before we start the main production run. Thanks to virtual sampling, this should be a mere formality. Because you've already perfected the design, color, and branding in the virtual stage, the golden sample serves as the final physical confirmation that the real-world product perfectly matches the approved digital prototype. It's your last chance to touch, feel, and wear the product. Approving this sample gives us the green light to purchase bulk materials and begin manufacturing, confident that there will be no surprises.

How Do You Find a Manufacturer with AI Sampling Capabilities?

You're sold on the benefits, but how do you find a factory partner who can actually offer this service? This technology is still relatively new, and not all manufacturers have invested in the necessary software, hardware, and skilled personnel.

Finding a tech-forward manufacturing partner requires you to ask the right questions during your vetting process. You need to specifically inquire about their 3D design and virtual sampling capabilities. A manufacturer who has truly embraced this technology will be eager to showcase it as a key competitive advantage.

What Questions Should You Ask Potential Suppliers?

When you contact a potential supplier, go beyond the standard questions about price and lead time. Ask them directly: "Do you offer 3D virtual sampling?" If they say yes, follow up with more specific questions: "What software do you use (e.g., CLO 3D, Browzwear)?" "Can you show me examples of virtual samples you've created for other clients?" "What is your turnaround time for a virtual sample from a tech pack?" A capable partner will be able to answer these questions confidently and provide a portfolio of their 3D work.

Why Is a Digital Material Library Important?

A truly advanced partner won't just create 3D models; they will have a digital material library. This is a database of their core fabrics that have been professionally scanned and digitized. This means that when you select "cotton twill" from their library, the virtual sample will use a simulation based on the real-world properties of their actual, in-stock fabric. This ensures a much higher degree of accuracy in the final product. At Shanghai Fumao Clothing, building out our digital material library is a top priority, as it's the key to creating truly predictive virtual samples.

Conclusion

AI virtual sampling is fundamentally changing the game for bulk hat orders. By enabling rapid, cost-effective, and collaborative design iterations, it empowers brands to be more creative, more agile, and more confident in their product decisions. It drastically cuts down development time and costs by replacing multiple rounds of slow and expensive physical sampling with instant 3D visualization. While it doesn't eliminate the need for a final, physical "golden sample" to confirm hand-feel and quality, it streamlines the entire journey to get there. To leverage this technology, you must seek out a modern, tech-forward manufacturing partner who has invested in the tools and talent to bring your designs to life in the digital world first.

If you are ready to accelerate your product development cycle and embrace a smarter way of creating custom headwear, our team is equipped to guide you. We have integrated AI virtual sampling into our core process to better serve our clients. Please contact our Business Director, Elaine, at elaine@fumaoclothing.com to learn more and start your first virtual sample.