Imagine your customers working or adventuring in the scorching desert heat. The sun is relentless, and the risk of heat stress is a constant danger. You've provided them with hats and water, but what if you could offer them a piece of wearable technology that actively fights the heat, powered by the very sun they're trying to escape? This sounds like science fiction, but it's closer to reality than you think.

The best way to source a product as specialized as a solar-powered cooling bandana is to partner with a technical manufacturer that has proven expertise in both performance textiles and wearable electronics integration. You won't find this product off-the-shelf. It needs to be custom-developed by combining three distinct technologies: thermoelectric cooling, flexible solar panels, and advanced, moisture-wicking fabrics.

As the owner of Shanghai Fumao Clothing, a company that has spent two decades evolving from traditional hats to technical headwear, this is precisely the kind of challenge that defines the future of our industry. It requires a deep, cross-disciplinary approach. Let me guide you through the technology, the design process, and how to find a partner capable of bringing this innovative product to life.

How Does the Cooling Technology Actually Work?

Before we can make one, we need to understand the science. This isn't a wet cloth that cools by evaporation. A solar-powered cooling bandana uses an active cooling engine, most likely a Thermoelectric Cooler (TEC), also known as a Peltier device.

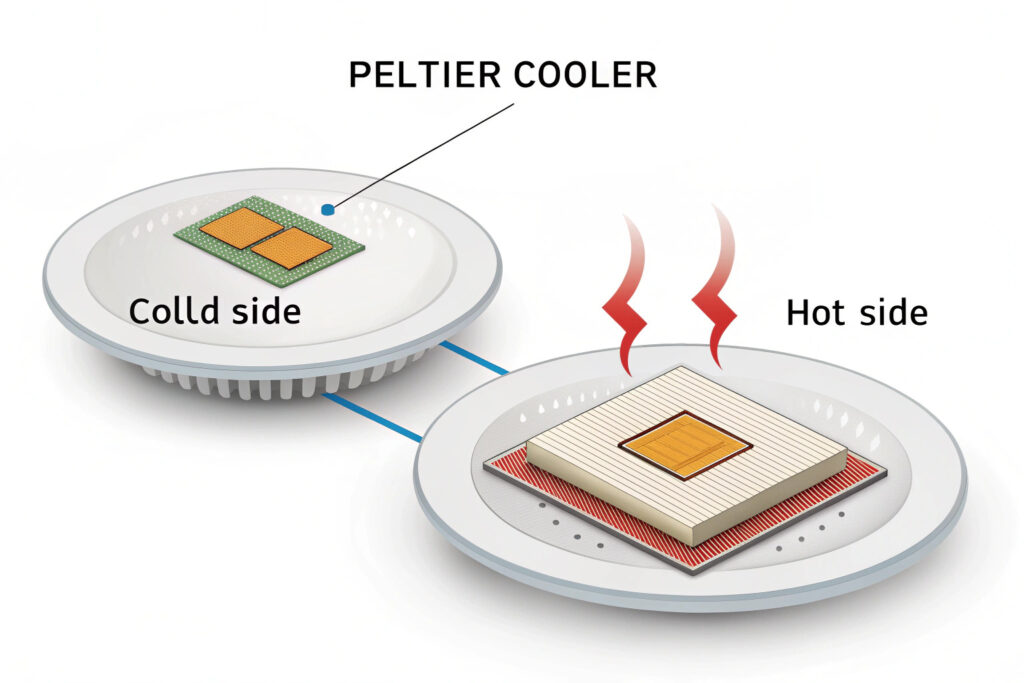

A Peltier device is a small, solid-state heat pump. It's a sandwich of two ceramic plates with special semiconductor materials in between. When a small electric current is applied:

- One side of the device gets cold.

- The other side gets hot.

The idea is to place the "cold side" against the wearer's skin, typically on the back of the neck where major blood vessels are close to the surface. This cools the blood as it circulates, helping to lower the body's core temperature. The "hot side" faces outward and is attached to a small, flexible heat sink to dissipate the heat into the air. The entire system is powered by a flexible solar panel integrated into the bandana's fabric.

This is the core technology. It's a mature concept used in things like portable coolers and CPU chillers. The innovation, and the manufacturing challenge, is miniaturizing it, making it flexible, and integrating it seamlessly into a comfortable piece of wearable fabric. This is a far cry from simple cut-and-sew and requires a deep understanding of both electronics and textiles.

Is this technology safe to wear?

Yes, when designed properly. The voltages and currents involved are very low. The main safety consideration is ensuring the "hot side" is properly ventilated and doesn't get hot enough to cause discomfort. A well-engineered product will have built-in temperature monitoring to shut the device off if it overheats. This is a standard feature in consumer electronics and is a key requirement for any wearable device, as outlined by safety certification bodies like UL Solutions.

How much cooling can it provide?

A small, wearable Peltier device won't feel like an air conditioner. It won't make you feel "cold" in the desert. Instead, it creates a noticeable cooling sensation on the skin that can make a significant difference in comfort and help mitigate the effects of heat stress. The goal is to provide a tangible sense of relief and help the body regulate its temperature more effectively. The performance depends on the efficiency of the device and how well it dissipates heat, a topic explored in-depth by resources like MIT Technology Review.

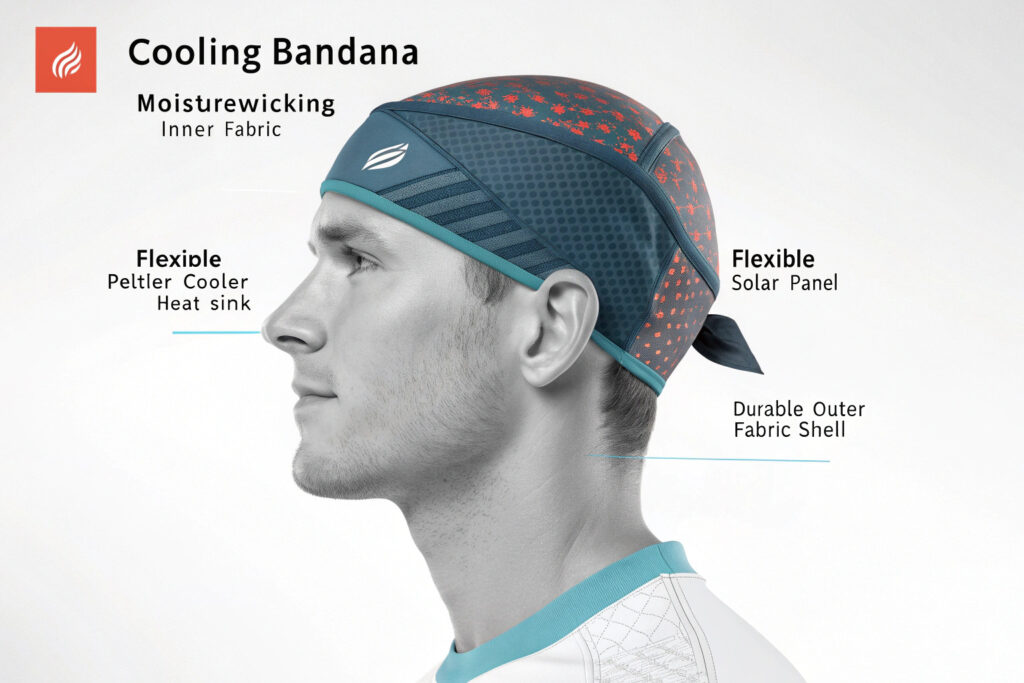

What Are the Key Components of the Bandana?

Developing this product is like assembling a high-tech puzzle. Each piece must be carefully selected and designed to work in harmony with the others. Sourcing this product means sourcing each of these components and finding a manufacturer who can integrate them.

The four essential components are:

- The Fabric Chassis: This is the bandana itself. It needs to be made from a high-performance, moisture-wicking technical fabric (like a polyester/spandex blend). The inner layer should be soft and comfortable against the skin, while the outer layer needs to be durable and UV-resistant.

- The Flexible Solar Panel: This is the power source. We would need to source thin, flexible, and robust solar panels designed for integration into textiles. These panels must be efficient enough to generate the small amount of power needed to run the TEC in direct sunlight.

- The Thermoelectric Cooler (TEC) Module: This is the cooling engine. We need a miniaturized, low-power Peltier device. It would be housed in a flexible, waterproof casing for safety and durability.

- The Flexible Heat Sink: This is crucial for dissipating heat from the hot side of the TEC. It could be a series of small, flexible aluminum fins or a special thermally conductive graphite film, which would be attached to the outer surface of the bandana.

As you can see, this is an exercise in systems integration. At Shanghai Fumao Clothing, our role would be to act as the master integrator. We would leverage our expertise in textiles while partnering with specialized electronics suppliers to source and test the solar and TEC components. This is the only practical way to develop such a complex product.

Where do you source flexible solar panels?

There are specialized companies that focus on creating flexible photovoltaic materials for unique applications. Companies like PowerFilm Solar in the US or other global suppliers found on electronics sourcing platforms like Digi-Key offer a range of lightweight, durable solar panels that are designed to be integrated into fabrics and other materials.

Does it need a battery?

For a purely solar-powered version, you could design it to work only when the sun is out, eliminating the need for a battery. However, a more advanced version would include a small, lightweight lithium-ion battery. This would allow the device to store energy and provide cooling even when you step into the shade for a few minutes, providing more consistent relief. This adds complexity and cost but significantly improves usability.

How Do You Develop and Prototype This Product?

You can't just draw this product and send it to a factory. Sourcing a solar-powered cooling bandana is a multi-stage R&D project that requires close collaboration with your manufacturing partner.

The development process would look like this:

- Proof of Concept (POC): The first step is to build a rough, non-wearable prototype just to prove the core technology works. This involves connecting the chosen solar panel to the TEC module and measuring the temperature drop and power consumption in a controlled environment.

- Component Integration & Ergonomics: Once the electronics are validated, the focus shifts to wearability. How do we embed these rigid components into a soft bandana without creating uncomfortable pressure points? This involves creating flexible housings, designing channels for wiring, and determining the optimal placement for comfort and performance.

- Alpha Prototype: This is the first wearable version of the product. It might be hand-stitched and a bit clunky, but it allows for initial testing of the fit, comfort, and real-world cooling effect. We would produce several of these for initial field testing.

- Beta Prototype (Pre-Production Sample): After gathering feedback from the alpha stage, we would refine the design and create a professional, factory-made beta prototype. This version would look and feel like the final product. It would undergo rigorous testing for durability, safety, and performance before being approved for mass production.

This iterative process is essential for a product this complex. It requires a manufacturing partner with a strong R&D department, not just a production line. They need engineers and product developers who can solve problems and turn a concept into a manufacturable reality. This is the kind of deep partnership required for sourcing and mass production.

How long would a development process like this take?

For a completely new product like this, a realistic timeline for development and prototyping (from concept to an approved pre-production sample) would be anywhere from 6 to 12 months. This includes time for sourcing components, testing, and multiple rounds of revisions.

How do you test the cooling effectiveness?

In a lab setting, we can use thermal imaging cameras to visualize the temperature drop on the cold side of the device and measure the surface temperature of the skin. For real-world testing, we would rely on feedback from human testers in a controlled hot environment (like a thermal chamber) or in the target environment (a desert) to gauge perceived comfort and effectiveness.

How Do You Find a Partner and Mass-Produce It?

Finding a single factory that specializes in both solar electronics and performance apparel is nearly impossible. Therefore, the key is to find a lead manufacturing partner who has experience with electronics integration and a strong network of specialized suppliers.

Here's how to approach the sourcing and production phase:

- Search for Technical Wearables Manufacturers: Look for factories that produce heated jackets, LED-integrated clothing, or other products that combine textiles and electronics. These companies will have the necessary experience with wiring, power sources, and component integration.

- Vet Their R&D Capabilities: During the vetting process, focus on their engineering team. Ask about their experience with similar projects. A true partner will be excited by the technical challenge, not intimidated by it. They should be able to discuss the potential challenges and propose solutions.

- Establish a Clear Development Agreement: Before committing to mass production, you need a separate agreement for the R&D and prototyping phase. This should outline the deliverables, timeline, and costs for developing the pre-production sample.

- Transition to Mass Production: Once you have an approved, tested, and certified prototype, you can then move to a standard mass production agreement. The manufacturer will use the prototype as the "golden sample" and set up a dedicated assembly line that includes steps for both sewing and electronics assembly/testing.

This is a high-level partnership. You are not just a buyer; you are a co-developer. You need a partner who can provide a complete, turnkey solution, from sourcing the niche electronic components to managing the final assembly and quality control.

What kind of certifications would this product need?

This product would likely need to comply with several regulations. In the US, this would include FCC regulations for electronic devices (to ensure it doesn't cause interference) and potentially CE marking in Europe. The battery, if included, would need its own certifications like UN38.3 for safe transport. A good manufacturer will be able to guide you through the required compliance testing.

What would the MOQ and cost be for such a product?

Given the high development cost and specialized components, the initial MOQ would likely be higher than a simple textile product, probably in the range of 1,000 to 3,000 units. The final unit cost would be a premium, reflecting the integrated technology. A rough, ballpark estimate might place it in the range of a high-end piece of consumer electronics rather than a simple bandana.

Conclusion

Sourcing a solar-powered cooling bandana is not a simple matter of finding a supplier on Alibaba. It's a forward-thinking product development project that requires a deep partnership with a highly capable and specialized manufacturer. The process is complex, involving the integration of thermoelectric coolers, flexible solar panels, and performance textiles into a single, seamless product.

However, for the right brand, the reward is significant: a truly innovative product that offers a real solution to a serious problem, with a powerful story and a high perceived value. It's a product that can define a brand as a leader in wearable technology.

At Shanghai Fumao Clothing, we are actively exploring these new frontiers. We have the textile expertise and the R&D-focused mindset to take on complex integration projects like this. If you are a brand with a bold vision and are looking for a partner to help you pioneer the next generation of wearable technology, we are ready to talk. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com to discuss your project.