Night runners are constantly seeking gear that enhances both their visibility and convenience. While standard LED vests and headlamps are common, a solar-charging LED visor represents a niche, innovative product combining hands-free lighting with sustainable charging. Sourcing such a specialized item requires a clear strategy, focusing on product specifications, reliable suppliers, and smart custom manufacturing.

To source solar-charging LED visors, you must define precise product requirements, identify specialized manufacturers on B2B platforms or at trade shows, and leverage custom manufacturing partnerships for development, prototyping, and bulk production. This process balances innovation with practical supply chain realities.

Finding a ready-made, wholesale solar LED visor is challenging because it's an emerging product category. Your journey will likely involve customizing existing cap designs or working with factories to develop a new product from scratch. The key is to partner with a manufacturer that has expertise in both headwear and integrating electronic components.

How to Define Your Product Specifications?

Before contacting suppliers, you must have a crystal-clear vision of your product. Ambiguity leads to misquotes and prototypes that miss the mark. Break down your visor into its core components: the power system, the lighting, and the headwear itself.

A detailed tech pack is your most important tool. It should include technical drawings, material lists, and performance criteria. For the solar and LED system, specify the battery capacity (e.g., 400mAh), desired LED brightness and beam type, and required lighting modes (e.g., steady, flashing). For the visor, decide on materials (like breathable polyester or performance fabrics), sizing, and any additional features like moisture-wicking bands or reflective logos.

Why are clear specs non-negotiable? They allow factories to provide accurate pricing and feasibility assessments. For instance, a solar panel's charging efficiency will dictate the battery size and runtime. Stating you need "IP54" sweat and weather resistance is better than just saying "waterproof." This precision prevents costly revisions later.

What Are the Critical Technical Requirements?

Focus on three systems:

- Solar Charging System: Specify the solar panel type (rigid or flexible), its minimum conversion efficiency, and the expected charge time under sunlight. Based on similar products, a full charge might take 1.5-2 hours for a small battery. Define the battery type (lithium-ion is common), its capacity, and the target runtime on a full charge for each light mode.

- Lighting System: Determine the LED count, color (white for seeing, red for warning), and brightness (lumens). Decide on user controls: a simple button or touch sensor. The lighting should offer multiple modes, such as fast flash, slow flash, and steady beam.

- Headwear System: The cap must be comfortable and durable. Choose between a traditional sewn cap or a molded visor. Materials should be lightweight, and the design must securely house the electronics without compromising balance or comfort. Consider an adjustable strap or buckle for universal fit.

How to Create an Effective Tech Pack for Factories?

Your tech pack should be a single source of truth. Use tools like Adobe Illustrator for vector drawings. Include:

- Dimensional Drawings: Front, side, and top views with all critical measurements.

- Bill of Materials (BOM): A table listing every component, its material, size, color, and supplier part number if available.

- Function Specifications: A clear description of how the solar charging and LED systems should operate.

- Packaging Instructions: How each unit should be folded, tagged, and boxed.

This clarity is what factories like shanghaifumaoclothing rely on to turn your concept into a producible item.

Where to Find Manufacturers and Suppliers?

You won't find this product on Amazon for bulk purchase. Your search must target the right tier of the supply chain: manufacturers and OEM/ODM suppliers capable of custom electronics integration.

The most efficient starting point is major B2B manufacturing platforms like Alibaba.com. Use specific keyword combinations such as "solar charging cap factory," "LED visor OEM," or "custom electronic hat." Filters like "Trade Assurance," "Verified Supplier," and those offering "OEM/ODM" services are crucial. While searching, you may find separate suppliers for solar components and caps, indicating a potential assembly partnership is needed.

Attending international trade shows is highly effective. Events like the Canton Fair (China), ISPO (Germany), or Magic (USA) allow you to meet factory engineers face-to-face, inspect sample quality, and discuss customization capabilities directly. This is often the fastest way to gauge a supplier's true expertise.

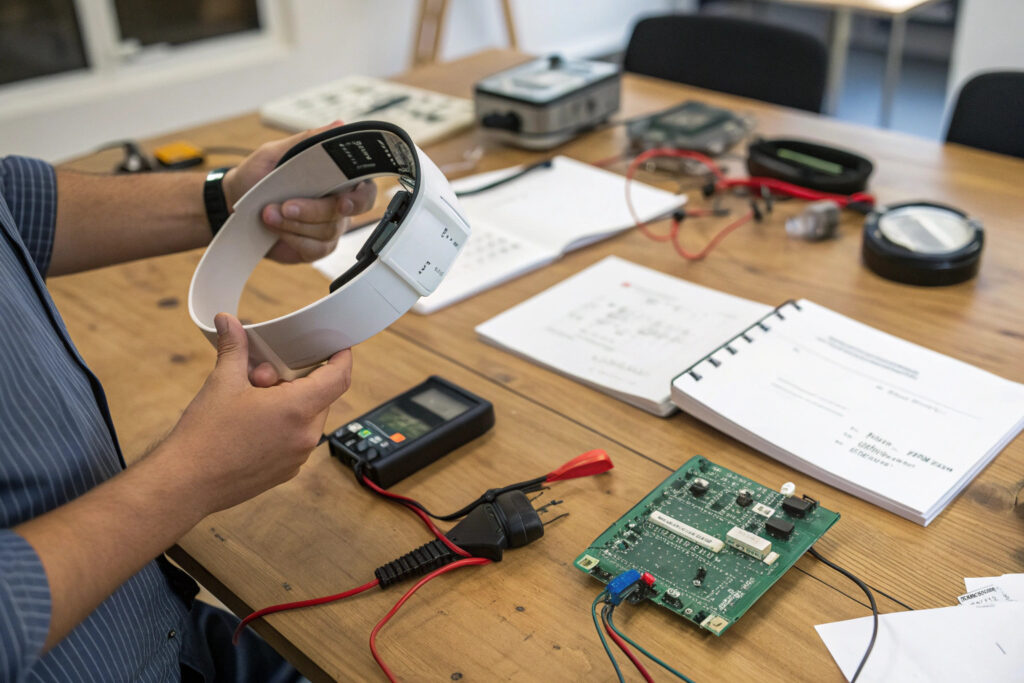

How do you vet a potential partner? Beyond minimum order quantities (MOQs), assess their R&D capability. Do they have an in-house design and electronics team? Request to see past projects involving wearable tech. Check for relevant certifications (like CE, FCC for electronics) and insist on visiting their factory, either in person or via a virtual tour, to audit their quality control processes.

What's the Best Sourcing Strategy for This Niche Product?

Given the product's complexity, a hybrid sourcing strategy often works best:

- Partner with an Integrated Headwear Factory: The ideal partner is a cap manufacturer (like shanghaifumaoclothing) with experience in tech integration. They can manage the entire process from fabric to final assembly.

- Component Sourcing with Final Assembly: If an integrated factory isn't available, you might source caps from one specialist and the solar/LED modules from another, then hire a third assembly factory. This offers more control but requires strong supply chain coordination.

- Using a Sourcing Agent: For newcomers, a reliable sourcing agent in key manufacturing hubs can navigate the landscape, vet factories, and manage quality inspections on your behalf, saving significant time and mitigating risk.

Which Certifications and Factory Audits Are Essential?

Safety and compliance are paramount for electronic wearables. Key certifications include:

- CE Mark: Essential for the European Economic Area, indicating compliance with EU health and safety standards.

- FCC ID: Mandatory for electronic devices sold in the USA, proving they don't cause harmful interference.

- RoHS: Ensures the product is free of specific hazardous materials.

A factory audit should check their Quality Management System (QMS), production lines, worker conditions, and component sourcing. A trustworthy partner will be transparent and welcome this scrutiny.

How to Navigate Customization and Sampling?

This is where your project comes to life. The sampling phase is an iterative investment to perfect your product. Expect to pay for each sample round, but view it as essential R&D.

Start by providing your tech pack to shortlisted suppliers. They will first create a prototype sample. This "looks-like" model tests the form, fit, and basic functionality. The next stage is the pre-production sample (PPS), made with actual materials and finalized electronics. This "works-like" model is what you thoroughly test for light output, comfort, battery life, and durability.

What should you test for? Beyond basic function, conduct real-world tests: how long does the solar panel take to charge under different light conditions? Does the visor remain comfortable during a run? Is the light bright enough for safety? Collect feedback from actual runners. Use this data to refine the design before approving mass production.

Why is a detailed contract vital? Before production, your contract must lock in all specifications, quality standards (AQL levels), payment terms (e.g., 30% deposit, 70% before shipment), delivery schedule, and protocols for handling defective goods. This document protects both parties and ensures alignment.

How Does the Multi-Stage Sampling Process Work?

The sampling process typically follows these stages:

| Stage | Purpose | What to Check |

|---|---|---|

| Prototype Sample | Test design, shape, and basic fit. | Overall look, dimensions, material feel. |

| Fit Sample | Perfect the wearability and sizing. | Comfort, adjustability, weight distribution. |

| Pre-Production Sample (PPS) | Finalize all details with production materials. | Full electronic function, final colors, stitching, and labels. |

Never approve mass production until the PPS is perfect. It is your benchmark for the final product quality inspection.

How to Negotiate Contracts and Protect Your IP?

Your contract should cover:

- Intellectual Property (IP) Clause: Clearly states that the product design and tech pack are your property. The factory cannot sell the same design to others.

- Payment Terms: Common terms are 30% deposit, 40% after sample approval, and 30% before shipment.

- Quality Acceptance Level: Use AQL (Acceptable Quality Level) standards to define the maximum number of minor/major defects allowed in an inspection.

- Delivery & Penalties: Include a clear delivery date and penalties for late delivery.

How to Manage Quality, Logistics, and Costs?

The final hurdle involves ensuring the bulk order matches your sample, gets to you efficiently, and remains profitable.

Implement structured quality control (QC). Hire a third-party inspection company to conduct checks during production ("During Production Inspection") and before shipment ("Pre-Shipment Inspection"). They will verify quantity, workmanship, function, and packaging against your approved sample and the agreed AQL standard.

Plan logistics early. For shipping from China, you can choose EXW (you handle all shipping), FOB (they get it to the port), or CIF (they cover insurance and freight to your nearest port). Using a freight forwarder is recommended. Be acutely aware of tariff codes and duties for your country; "sports caps" and "LED articles" may have different classifications and duty rates.

How to calculate the true landed cost? Your total cost isn't just the unit price. You must add:

- Sample costs

- Tooling/mold fees (if any)

- International shipping and insurance

- Import duties and taxes

- Any local warehousing or last-mile delivery

Only by calculating this "landed cost per unit" can you determine your final retail price and ensure a healthy profit margin.

What Are the Key Steps in Quality Control Inspection?

A professional Pre-Shipment Inspection usually involves:

- Random Sampling: Inspectors randomly select units from the finished batch based on a statistical plan.

- Visual Check: Looking for defects in stitching, printing, and assembly.

- Function Test: Charging the visor and testing every LED mode.

- Measurement Check: Verifying product dimensions match the tech pack.

- Packaging Check: Ensuring the retail packaging is correct and undamaged.

The inspector then provides a detailed report with pass/fail status and photographic evidence.

How to Optimize Shipping and Handle Import Tariffs?

Work with a freight forwarder to choose the best Incoterm. For new importers, FOB (Free On Board) is often a good balance. You need to determine the correct Harmonized System (HS) code for your product. For a solar LED visor, you may need to consult customs brokers, as it could fall under "headgear" (6506) or "electrical machinery" (8543). Getting this wrong can lead to delays, fines, or incorrect duty payments. Properly managing this is as crucial as the manufacturing itself for companies like shanghaifumaoclothing that export globally.

Conclusion

Sourcing a solar-charging LED visor is a project that blends product vision with supply chain expertise. The path involves clearly defining an innovative product, diligently finding and vetting specialized manufacturers, meticulously guiding the customization process, and rigorously managing quality and logistics. Success lies in partnering with a supplier that has the technical capability to execute your vision reliably and at scale.

For a project of this nature, partnering with a manufacturer that offers comprehensive ODM/OEM services from design to delivery is crucial. If you are looking to develop this or any other innovative headwear product, I recommend contacting the team at Shanghai Fumao Clothing. You can reach out to their Business Director, Elaine, to discuss your specific requirements at elaine@fumaoclothing.com.