For global buyers and brands looking to serve the Sikh community with high-quality headwear, sourcing Sikh turbans (often called "Sikh turban caps" or "patkas") with quick-dry technology presents a unique challenge. It requires blending cultural respect with technical textile innovation. Standard turbans are traditionally made from natural fabrics like cotton or silk, which can become heavy and uncomfortable when wet. Integrating modern quick-dry performance without compromising the fabric's drape, comfort, and cultural appropriateness is key.

The most effective way is to partner with a specialized manufacturer that possesses both expertise in performance fabrics and the cultural sensitivity to produce authentic, respectful headwear. You need a partner who can source advanced technical fabrics and engineer them into the correct styles and sizes. As a comprehensive hat solutions provider with over 20 years in the industry, Shanghai Fumao Clothing bridges this gap. We combine access to innovative textiles with agile development to create turbans that meet both functional needs and cultural standards.

This guide will walk you through the critical steps, from understanding fabric technology to finding the right manufacturing partner, ensuring you can successfully bring this niche product to market.

What is Quick-Dry Technology and Why is it Important for Turbans?

Quick-dry technology refers to fabrics engineered to pull moisture (like sweat) away from the skin to the fabric's surface, where it spreads and evaporates rapidly. For a Sikh turban, which is worn closely for long periods and can be several meters of fabric, this is crucial. It maintains comfort, hygiene, and the garment's dignified appearance during daily activities, work, or sports.

Beyond basic comfort, this functionality respects the practical needs of the wearer. A standard cotton turban can retain moisture, leading to skin irritation, an uncomfortably heavy feel, and even the need for more frequent washing, which wears out the fabric faster. A quick-dry turban offers a modern solution that aligns with an active lifestyle while upholding the article of faith.

Which Fabrics Are Best for Quick-Dry Turbans?

The ideal fabrics are not single materials but advanced blends or specially treated textiles. Key options include:

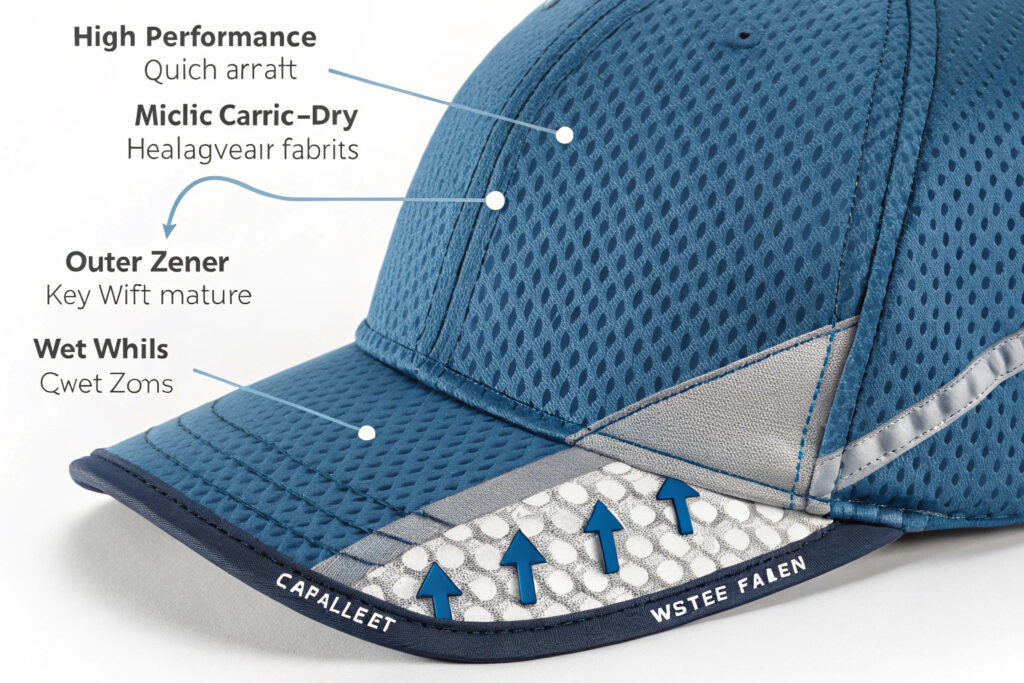

- High-Tech Polyester or Nylon Blends: These synthetic fibers are inherently hydrophobic and can be engineered with micro-channels for capillary action. They are the core of most moisture-wicking activewear and offer superior durability and consistent performance.

- Treated Natural Fibers: Cotton can be treated with a moisture-wicking finish. More sustainable innovations include blends with Tencel™ (Lyocell) or Bamboo Silk (BAMSILK), which have natural breathability and can be enhanced with technical finishes.

- Construction Matters: The choice between a woven or knitted construction depends on the desired drape and structure. A technical knit may offer more stretch and comfort, which is a key consideration in headwear ergonomics.

How Does This Technology Integrate with Traditional Turban Design?

Integration is the most critical step. The fabric must not only perform but also possess the right hand feel, weight, and drape. A turban fabric that is too stiff, too shiny, or doesn't fold neatly will be unacceptable.

This is where working with an experienced manufacturer is vital. They will source the appropriate technical fabric and then rigorously test it in the specific context of a turban. This involves checking for colorfastness to ensure colors don't run, shrinkage control so the size remains consistent, and seam integrity if the design requires stitching. At Shanghai Fumao Clothing, our in-house CNAS-certified lab allows us to conduct these precise tests, ensuring the final product is both high-performing and culturally authentic.

How to Find and Evaluate a Manufacturer for This Niche Product?

Sourcing a culturally specific technical product requires a more targeted approach than general hat sourcing. You need to identify partners with either direct experience or the proven adaptability to develop it correctly. The goal is to find a factory that asks informed questions about style, size, and fabric preferences from the start.

Your evaluation must go beyond basic manufacturing capability to include cultural competency and technical R&D skill. A strong partner will see this as a collaborative development project.

Where Should You Look for Specialized Manufacturers?

Begin your search on platforms and in regions known for technical capability and supply chain depth:

- Technical Textile & OEM Hubs: Focus on B2B platforms and regions known for functional apparel. A manufacturer based in a major textile cluster like Keqiao, China, has inherent advantages for accessing a wide range of performance fabrics quickly.

- Verify Niche Experience: Use professional platforms like LinkedIn to research suppliers and look for case studies or client testimonials that mention culturally sensitive or technical product development.

- Leverage Industry Networks: Attend major global apparel sourcing fairs where you can meet suppliers in person, feel fabric samples, and assess their expertise directly. This is often the best way to initiate a complex project.

What are the Key Questions to Ask a Potential Supplier?

Your initial inquiry should separate qualified partners from the rest. Essential questions include:

- "Can you source or recommend specific quick-dry fabrics suitable for headwear? Can you provide lab test reports for their performance?" This tests their textile network and commitment to verification.

- "Do you have experience producing headwear for specific cultural or religious communities? How do you ensure design accuracy and respect?"

- "What is your development process for a new technical product like this? What are the stages and timelines for sampling?" This probes their project management and R&D depth.

- "What is your quality control protocol for performance attributes like moisture management?" This ensures they have checks beyond basic stitching.

What Does the Development and Production Process Look Like?

Creating a successful quick-dry turban follows a structured, collaborative process from concept to shipment. Rushing this process risks failures in both function and form. A clear timeline with agreed milestones protects both you and the manufacturer.

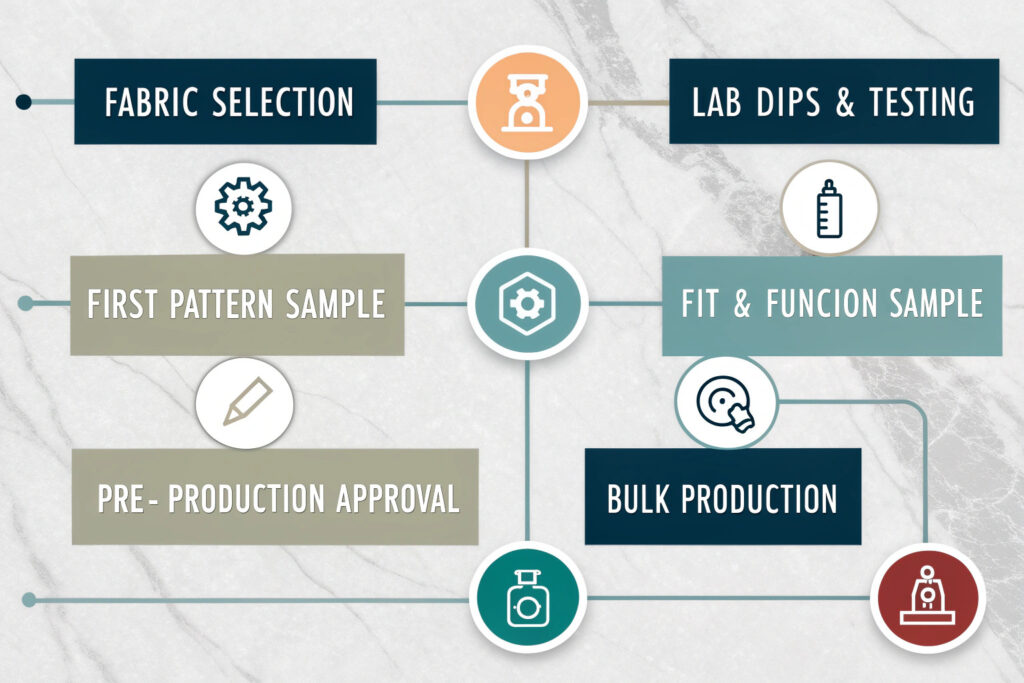

Expect this to be a multi-stage project involving fabric approval, multiple sample rounds, and stringent testing before bulk production can begin.

What Are the Critical Steps in the Sampling Phase?

The sampling phase is where your product comes to life. It typically involves:

| Sample Stage | Primary Purpose | Key Checkpoints |

|---|---|---|

| Fabric & Lab Dip Approval | To confirm the color, hand feel, and performance of the chosen textile. | Receive physical swatches and laboratory test reports for quick-dry capability. |

| First Prototype Sample | To assess the basic pattern, size, and styling. | Check dimensions, overall shape, and cultural appropriateness of the style. |

| Fit & Function Sample | To test the garment made from the actual production fabric. | Wear-test for comfort, moisture-wicking performance, and finalize all details. |

| Pre-Production Sample | The final reference, made on production lines with all trims. | This is your signed approval for bulk production. No changes after this. |

How is Quality Controlled for Performance and Consistency?

Robust quality control (QC) is non-negotiable. For a quick-dry turban, QC must extend beyond standard stitching checks.

- In-House Fabric Testing: Before cutting, the fabric batch should be tested again to ensure it meets the performance benchmarks set during sampling.

- Inline Production Checks: Supervisors check seams, size, and appearance as the turbans are made to catch issues early.

- Final Random Inspection: Following the AQL (Acceptable Quality Limit) standard, a percentage of the finished order is inspected. For performance wear, this should include a simple function test.

- Supply Chain Transparency: Advanced manufacturers offer track-and-trace systems, providing peace of mind that every batch meets the agreed international compliance standards.

Conclusion

Sourcing Sikh turban caps with quick-dry technology successfully hinges on a strategic partnership. It requires identifying a manufacturer with deep access to innovative textile suppliers, the R&D agility to integrate technology into appropriate designs, and the cultural sensitivity to produce a respectful product. By focusing on fabric expertise, asking the right due diligence questions, and following a meticulous development process, you can bring a high-value, functional product to a dedicated market.

If you are looking for a manufacturing partner that combines technical fabric innovation with comprehensive, respectful OEM development for the global market, we are here to help. Shanghai Fumao Clothing is equipped to guide you from fabric selection through to certified production. For a detailed discussion on developing your line of quick-dry Sikh turbans, please contact our Business Director, Elaine, at elaine@fumaoclothing.com.