Are you sourcing protective gear for travelers, workers, or organizations operating in high-risk malaria regions? Finding commercially available pre-treated safari hats is a challenge. The solution lies not in finding a ready-made product on a shelf, but in partnering with a specialized manufacturer to engineer a hat that is both effective and compliant. This requires a strategic approach that prioritizes precise insecticide application, fabric technology, and adherence to international health guidelines.

Permethrin, a synthetic insecticide, is a frontline defense when bonded to fabrics like those in a safari hat. It works by repelling and killing mosquitoes on contact, providing a crucial physical and chemical barrier. This makes it a valuable tool for personal protection during hours when people are active and not under bed nets. However, to be effective in malaria zones, the treatment must be durable, correctly dosed, and applied in a way that maximizes safety and efficacy.

The path to sourcing these hats involves three core pillars: technical collaboration on fabric treatment, compliance verification with health and safety standards, and strategic supply chain planning. As an experienced manufacturer, Shanghai Fumao Clothing can guide you through this process, from fabric selection and treatment method to final product certification, ensuring your end-users are properly protected.

Why Use Permethrin-Treated Clothing in Malaria Prevention?

Integrating permethrin-treated clothing, including hats, into a comprehensive malaria prevention strategy addresses a critical gap in protection. While long-lasting insecticidal nets are highly effective for nighttime indoor use, they do not protect people when they are outdoors or active during dusk and dawn—peak biting times for some mosquitoes. Treated clothing provides mobile, personal protection during these vulnerable periods.

The evidence points to the value of this approach. Analysis of trials in high-risk settings like refugee camps and military deployments found that insecticide-treated clothing may reduce the incidence of clinical malaria by approximately 50%. For organizations sending personnel into the field, safari hats are a logical component of a full treated-clothing ensemble, offering crucial protection for the head and neck, which are common targets for mosquitoes.

What Does the Research Say About Efficacy?

Research underscores that the protective effect is significant, particularly in the absence of universal bed net coverage. Consolidated evidence indicates a potential 50% reduction in malaria risk with insecticide-treated clothing. Other studies on insecticide-treated materials in experimental settings have shown they can increase mosquito mortality and reduce blood-feeding rates. The effectiveness is not just about killing mosquitoes; it also includes repellency (deterrence) and inhibiting feeding, creating multiple layers of defense. This multi-modal action is why health authorities recognize permethrin-treated garments as a valuable part of personal protection strategies for travelers.

How Does Treated Clothing Fit into a Broader Protection Strategy?

It is critical to view treated hats and clothing as a complementary intervention, not a standalone solution. The World Health Organization (WHO) emphasizes integrated approaches. For maximum protection, treated clothing should be used alongside other measures:

- Topical Repellents: Applied to exposed skin for areas not covered by clothing.

- Chemoprophylaxis: Anti-malarial medication as prescribed.

- Environmental Awareness: Avoiding high-risk areas during peak biting times.

A treated safari hat is most effective as part of a full suit of treated apparel, creating a comprehensive physical barrier enhanced with insecticide. This layered defense is the gold standard for non-net protected hours.

What Are the Critical Technical Specifications for Effective Hats?

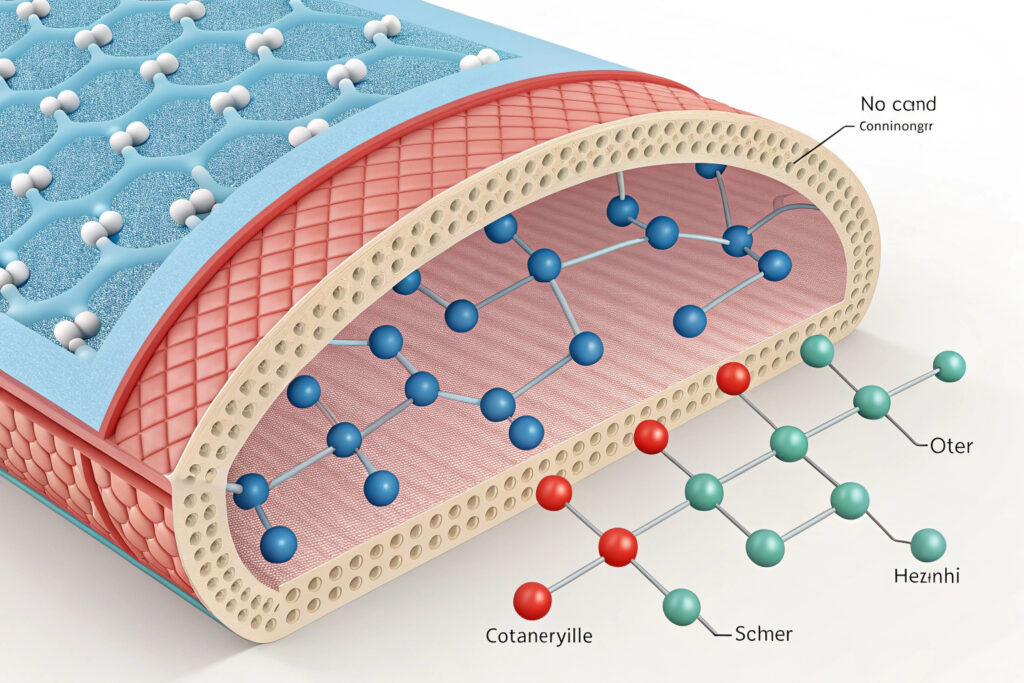

The efficacy of a permethrin-treated hat is not a given; it is a result of precise engineering. Simply spraying a hat with an off-the-shelf repellent is insufficient for reliable, long-term protection in high-risk zones. Professional-grade treatment involves specific dosage, bonding technology, and fabric construction to ensure the insecticide remains active on the outer surface where it is needed most, while minimizing unnecessary exposure to the wearer.

The cornerstone of effectiveness is durable bonding. The permethrin must be applied in a way that it withstands wear, sunlight (UV exposure), and a limited number of washes. Leading treatment formulations bond to fibers for up to 6 weeks or 6 washes. For a commercial product, industrial methods like factory impregnation can offer even greater durability. Crucially, research highlights that the insecticide's activity is primarily needed on the outer layer of the fabric; excessive permeation to the inner layer is undesirable as it increases the risk of skin contact without enhancing protection.

What Are the Key Fabric and Treatment Parameters?

| To source or manufacture an effective hat, you must specify and control these parameters: | Parameter | Importance & Specification | Source / Rationale |

|---|---|---|---|

| Target Dosage | The concentration of permethrin per unit area of fabric. Must be sufficient to kill/repel but within safe limits. | Dosages are often cited in mg/m² (e.g., 2% w/w). A manufacturer should follow WHO or EPA guidelines for treated materials. | |

| Treatment Method | How the insecticide is applied (e.g., factory bath impregnation vs. post-production spraying). | Factory impregnation typically offers more uniform and durable bonding than individual spray application. | |

| Fabric Choice | The base material (e.g., cotton, polyester, blends) affects how well it holds the treatment. | Fabric must be compatible with permethrin. Treated fabrics should be tested for efficacy post-production. | |

| Durability | The treatment must resist degradation from UV light, abrasion, and washing. | Efficacy should remain through a declared number of launderings (e.g., "up to 6 washes") before re-treatment is needed. | |

| Safety Profile | Treatment must minimize permethrin transfer to the skin. | Research emphasizes that insecticide activity should be concentrated on the outer fabric layer. |

Why is Factory-Level Impregnation Superior for Sourcing?

For bulk sourcing, factory-level impregnation is the preferred method. This process ensures:

- Consistency: Every hat in the production batch receives a uniform, measured dose.

- Durability: Industrial methods often create a stronger bond between the permethrin and the fabric polymer, leading to longer-lasting efficacy compared to a topical spray.

- Quality Control: The treatment can be integrated into the manufacturing workflow with controlled testing at various stages.

When discussing production with Shanghai Fumao Clothing, the focus would be on selecting a fabric suitable for this impregnation process and establishing a rigorous testing protocol to verify the initial and post-wash insecticide concentration.

How to Navigate Compliance and Sourcing Logistics?

Bringing a compliant and effective permethrin-treated hat to market involves navigating regulatory landscapes, ensuring ethical production, and planning for post-purchase care. This is not just a procurement exercise but a supply chain management challenge with health implications.

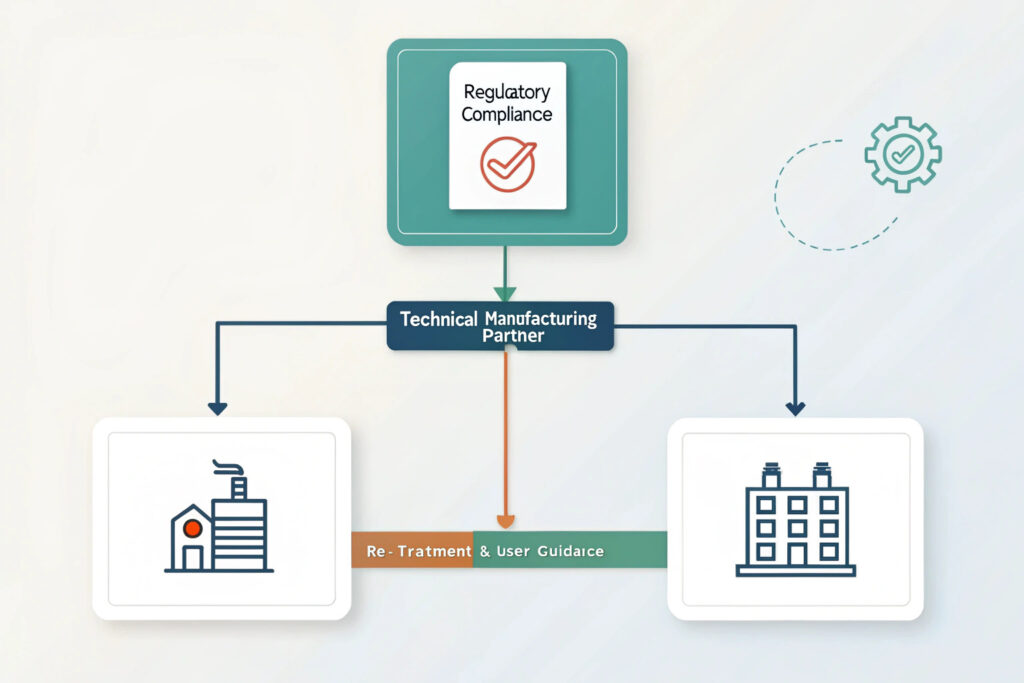

The first rule is regulatory compliance. The insecticide used must be approved for textile application by relevant authorities in both the country of manufacture and the destination country. For example, permethrin is widely used and approved in many countries, but regulations can vary. The WHO provides guidelines and specifications for insecticides used in disease control, which serve as an international benchmark. Any reputable manufacturer must be able to provide documentation proving the insecticide's registration and the safety of its application process.

What Are the Essential Steps in the Sourcing Process?

- Define Specifications and Partner: Based on the technical parameters above, create a product specification sheet. Partner with a manufacturer like Shanghai Fumao Clothing that has experience or capability in technical textile finishing and a willingness to collaborate on testing and certification.

- Verify Certifications and Safety Data: Request and audit the manufacturer's documentation on the permethrin source, its safety data sheets (SDS), and any existing certifications for treated fabrics. Ensure their process includes testing for final permethrin concentration.

- Plan for Labeling and User Education: The end product must have clear labeling indicating it is insecticide-treated, the number of effective washes, and safe handling instructions. Sourcing should include planning for user guidance, potentially including access to re-treatment kits for end-users to refresh the hat's efficacy after its effective lifespan.

- Consider the Supply Chain Context: For large orders destined for specific organizations (e.g., NGOs, military, corporate teams), logistics such as import regulations, storage, and distribution must be factored into the sourcing plan from the outset.

What Are Common Pitfalls to Avoid?

- Assuming All Treatments Are Equal: A DIY spray treatment is not equivalent to industrial impregnation in terms of durability or consistency.

- Overlooking Wash Resistance: The product's value diminishes rapidly if the treatment washes out after one or two cycles. Durability must be a key sourcing criterion.

- Neglecting Re-treatment Planning: The hat is a consumable health device. Failing to provide users with a clear re-treatment protocol or access to kits undermines the long-term protective value.

- Ignoring Local Regulations: Shipping a pesticide-treated product across borders without ensuring compliance can lead to seizures or legal issues.

Conclusion

Sourcing permethrin-treated safari hats for malaria zones is a specialized endeavor that transcends simple apparel procurement. It is an exercise in applied public health logistics, requiring a deep understanding of entomology, textile chemistry, and regulatory frameworks. The goal is to produce a durable, effective, and safe piece of protective equipment that integrates seamlessly into a user's broader malaria defense strategy.

The process hinges on a technical partnership with a manufacturer capable of precise insecticide application and quality assurance. From selecting the right fabric and treatment method to verifying dosage and planning for the product's lifecycle, every step must be guided by efficacy and safety data. The evidence supports the value of this intervention, particularly for mobile populations and outdoor workers, making it a responsible and potentially life-saving inclusion in gear for high-risk regions.

If you are looking to develop or source a line of compliant, high-efficacy permethrin-treated safari hats or other protective clothing, partnering with an experienced technical manufacturer is the critical first step. Shanghai Fumao Clothing is equipped to be that partner. Our expertise in garment manufacturing, combined with a collaborative approach to technical challenges, allows us to engineer solutions that meet stringent protective standards. To discuss your project and develop a product specification, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's create gear that offers real protection where it matters most.