Finding reliable glow-in-the-dark safety caps for night workers requires careful planning and verification. You need products that provide genuine protection, maintain consistent visibility, and meet international safety standards. Many safety managers struggle with suppliers who can't deliver consistent quality or proper certifications.

The key to sourcing quality glow-in-the-dark safety caps lies in partnering with manufacturers who specialize in photoluminescent materials, hold relevant safety certifications, and understand industrial workplace requirements.Proper sourcing ensures worker safety while providing long-term value through durable, reliable products. At AceAccessory, a core brand of shanghaifumaoclothing https://shanghaiGarment.com.

This comprehensive guide will walk you through the entire sourcing process, from material specifications to supplier verification and quality control.

What material specifications ensure effective nighttime visibility?

The material composition directly determines how well safety caps perform in low-light conditions. Not all photoluminescent materials provide the same level of performance or duration. Understanding the technical specifications helps you avoid products that fail when needed most.

Effective glow-in-the-dark safety caps use high-quality photoluminescent pigments with long afterglow duration, high initial brightness, and consistent charging capability.Premium materials maintain visibility for 8+ hours after charging and withstand industrial conditions without performance degradation.

The technology behind photoluminescent materials involves precise engineering and quality control. Here's what makes these materials work reliably in industrial settings.

How long should the glow last for full night shifts?

For standard 8-hour night shifts, safety caps should provide visible illumination for at least 6-8 hours after complete charging. The glow intensity must remain sufficient for worker identification and basic navigation throughout the entire shift. Premium photoluminescent pigments can maintain functional visibility for 10-12 hours.

The afterglow duration depends on pigment quality and charging conditions. Strontium aluminate based pigments typically offer the longest afterglow, while older zinc sulfide variants fade more quickly. Always test samples in actual work conditions to verify performance matches supplier claims before bulk ordering.

What lighting conditions are needed for proper charging?

Photoluminescent materials require adequate light exposure to "charge" effectively. Natural sunlight provides the fastest charging (15-30 minutes for full charge), while standard workplace lighting may require 1-2 hours. The caps should maintain adequate glow when charged under normal industrial lighting conditions.

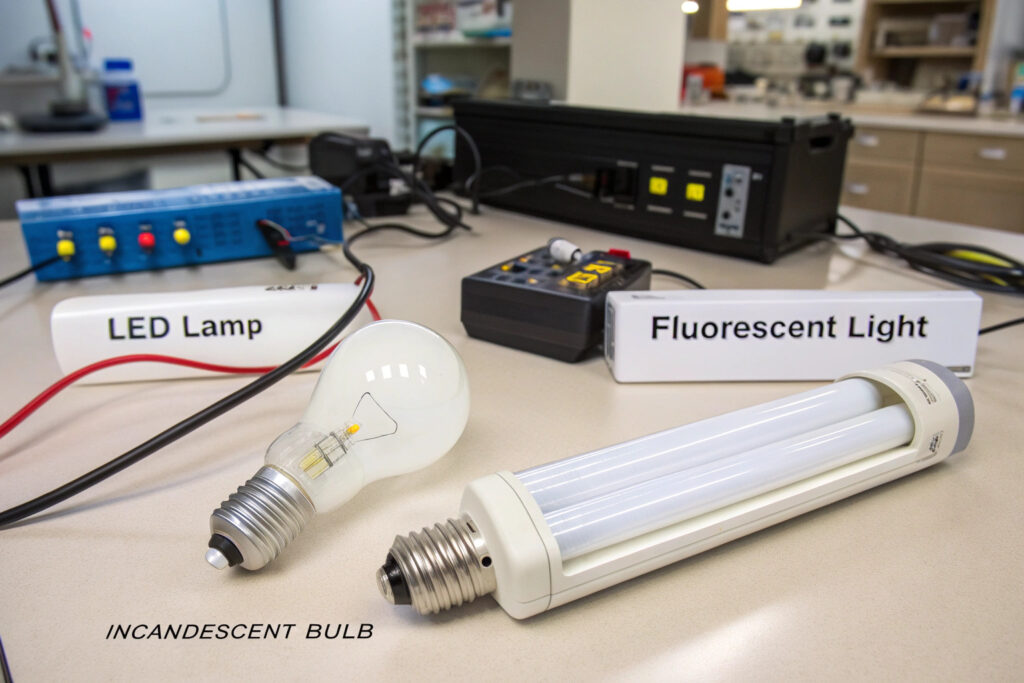

Charging efficiency varies by light source type. LED and fluorescent lights work well, while incandescent bulbs may be less effective. Some advanced materials can charge under low-light conditions, making them suitable for indoor-outdoor transition work environments. Verify specific charging requirements with your manufacturer during sample testing.

What certifications are essential for industrial safety compliance?

Safety certifications are mandatory for protective equipment in regulated industries. They provide independent verification that products meet established safety standards and performance requirements. Without proper certifications, you risk worker safety and regulatory compliance issues.

Essential certifications include ANSI/ISEA 107 for high-visibility apparel, EN ISO 20471 for European markets, and ANSI Z89.1 for industrial head protection. These certifications ensure caps provide both visibility and physical impact protection in workplace environments.

Certification compliance involves rigorous testing and ongoing quality assurance. Here's what each standard covers and why it matters for your sourcing decision.

Does ANSI/ISEA 107 apply to photoluminescent safety caps?

ANSI/ISEA 107 addresses high-visibility safety apparel and includes requirements for performance materials. While primarily focused on reflective strips, the standard's performance categories help evaluate photoluminescent materials for consistent visibility and durability in various lighting conditions.

The standard defines three performance classes based on material area and configuration. For safety caps, Class 1 typically applies, but night work in complex or high-risk environments may require Class 2 or 3 levels. Manufacturers familiar with ANSI standards can advise on appropriate compliance levels for specific applications.

What international standards ensure global compliance?

For international operations, key standards include EN ISO 20471 (Europe), AS/NZS 4602 (Australia/New Zealand), and JIS T 8127 (Japan). Each standard has unique testing requirements for luminance, color fastness, and durability. Understanding these regional differences is crucial for multinational companies.

Many manufacturers hold multiple certifications to serve global markets. We maintain compliance with major international standards through regular third-party testing, ensuring our safety caps meet requirements across different regions. This global compliance approach simplifies sourcing for companies with international operations.

How to verify supplier capabilities for safety products?

Verifying supplier capabilities goes beyond basic manufacturer qualifications. For specialized safety equipment like glow-in-the-dark caps, you need suppliers with specific expertise in photoluminescent technology and industrial safety compliance.

Verify supplier capabilities through factory audits, material testing reports, certification documentation, and reference checks with existing industrial clients. Specialized safety gear requires specialized manufacturing processes and rigorous quality control systems.

Proper due diligence prevents quality issues and ensures consistent product performance. Here are key verification steps for potential suppliers.

What manufacturing processes ensure consistent quality?

Consistent glow quality requires precise pigment mixing, even material distribution, and controlled production environments. The manufacturing process should include spectrophotometer testing for luminance consistency and automated quality checks for coating uniformity across all caps.

Advanced manufacturers use computer-controlled dispensing systems to maintain exact pigment ratios across production batches. This ensures every cap delivers identical glow performance and duration. The production process should also include accelerated aging tests to verify long-term material stability under various environmental conditions.

How important is supplier experience with industrial standards?

Supplier experience with industrial safety standards is critical for compliance and product reliability. Manufacturers familiar with certification processes understand the technical requirements and testing protocols needed to maintain compliance. This expertise prevents costly certification failures and production delays.

Experienced suppliers can provide valuable guidance on standard interpretation and application-specific compliance strategies. We've assisted numerous industrial clients in selecting appropriate certification levels based on their specific work environments and risk assessments through our technical consultation services. Verify our manufacturing capabilities: factory audit report & production line showcase, industrial client cooperation cases, custom specification consultation.

What quality control prevents defective safety products?

Quality control for glow-in-the-dark safety caps requires specialized testing beyond standard head protection checks. Defective photoluminescent materials can fail when needed most, creating serious safety risks for night workers in industrial environments.

Essential quality control measures include luminance testing, charging cycle durability, environmental resistance verification, and impact protection validation.These tests ensure caps perform reliably under actual working conditions throughout their service life.

Proper quality control involves both pre-production and production phase testing. Here's how to implement effective quality assurance programs.

How to test glow performance before bulk ordering?

Before bulk ordering, conduct real-world performance tests using production samples. Test the caps in actual work environments, measuring glow intensity at regular intervals throughout a full shift. Compare performance against established benchmarks for your specific industry requirements.

Laboratory testing should include spectrophotometer measurements of initial luminance and decay curves. The caps should meet or exceed the luminance levels specified in relevant safety standards. We provide comprehensive sample testing kits that allow clients to verify performance in their specific work conditions before committing to large orders.

What environmental factors affect long-term durability?

Environmental factors like UV exposure, temperature extremes, moisture, and chemical exposure can degrade photoluminescent materials over time. Quality caps should withstand typical industrial conditions without significant performance loss. Key durability tests include UV resistance, water immersion, temperature cycling, and chemical exposure testing.

The protective coating over photoluminescent materials plays a crucial role in environmental resistance. High-quality caps use UV-stable, abrasion-resistant coatings that protect the glow materials while maintaining optimal light-transmission properties. Verify that suppliers test for these environmental factors during product development and quality control.

Conclusion

Sourcing effective glow-in-the-dark safety caps requires careful attention to material specifications, safety certifications, supplier capabilities, and quality control processes. The right products provide reliable visibility throughout night shifts while meeting all relevant industrial safety standards.To explore bulk pricing, download full certification documents, or request free product samples for on-site testing, visit shanghaiGarment.com’s glow-in-the-dark safety cap sourcing hub.

If you're looking for a manufacturing partner for glow-in-the-dark safety caps, Global-Caps has extensive experience in producing certified safety headwear with reliable photoluminescent properties. Our technical team can help you select the right specifications for your specific industrial application. Contact our Safety Products Director Elaine at elaine@fumaoclothing.com to discuss your requirements and request samples for testing.