Finding reliable flame-resistant (FR) balaclavas is critical for protecting oil and gas workers from flash fire hazards. Yet, the search can be frustrating. Vague product claims, confusing standards, and uncertain supply chain reliability can leave safety managers at risk.

To successfully source FR balaclavas for the oil and gas industry, you must prioritize three core elements: strict compliance with recognized safety standards like NFPA 2112, sourcing from specialized manufacturers with verified expertise in high-performance FR fabrics, and establishing a supply chain capable of supporting both small prototype orders and large-scale production. This process requires moving beyond general protective equipment suppliers to partners who understand the specific thermal and durability demands of oilfield environments.

Let's break down this sourcing process into actionable steps, from understanding the mandatory requirements to finding and vetting the right manufacturing partner.

What Are the Mandatory Safety Standards for FR Balaclavas?

Navigating safety standards is the first and most critical step. Procuring a balaclava that does not meet the correct, enforceable standards is a fundamental safety and compliance failure. In the oil and gas industry, this is not about optional features but mandatory, life-preserving specifications.

The foundational standard for FR balaclavas in North American industrial settings is NFPA 2112. This standard explicitly covers the design, performance, and certification of flame-resistant garments, including "shrouds/hoods/balaclavas". It sets the benchmark for protection against short-duration thermal exposures from flash fires. Compliance is non-negotiable for reputable manufacturers. Simply claiming a fabric is "fire-resistant" is insufficient; the finished garment must be certified to this standard. You will often find this certification listed directly on the garment's permanent label.

How do I verify if a balaclava is NFPA 2112 compliant?

Verification requires looking for specific, tangible evidence. First, inspect the product label. A compliant balaclava will have a permanent label stating it meets "NFPA 2112". Second, request the manufacturer's certification documentation. Legitimate suppliers can provide test reports from accredited third-party laboratories (e.g., UL, SGS) that verify the garment's performance against the standard's stringent tests, such as the Thermal Protective Performance (TPP) rating and flame resistance after laundering. Third, understand the scope. NFPA 2112 certification applies to the complete, finished garment—not just the fabric. This ensures that all components, including seams, threads, and any hardware, contribute to the required protection level.

Are there other important certifications beyond NFPA 2112?

Yes, depending on the specific hazards and geographic region. A key complementary standard is ASTM F1506, which sets performance requirements for FR textiles used in electrical arc-rated clothing. Some advanced balaclavas are designed for "dual-hazard" protection, meaning they are certified to protect against both flash fire (NFPA 2112) and electric arc flashes. For operations in Europe, the EN ISO 11612 standard for heat and flame protective clothing is the common benchmark. Furthermore, the fabric itself often comes with its own pedigree. For instance, sourcing balaclavas made from fabrics by leading producers like TenCate Protective Fabrics, which are engineered to exceed international norms for industrial sectors including petrochemicals, adds a significant layer of verified quality and performance assurance.

Where Can I Find Reliable Manufacturers of FR Balaclavas?

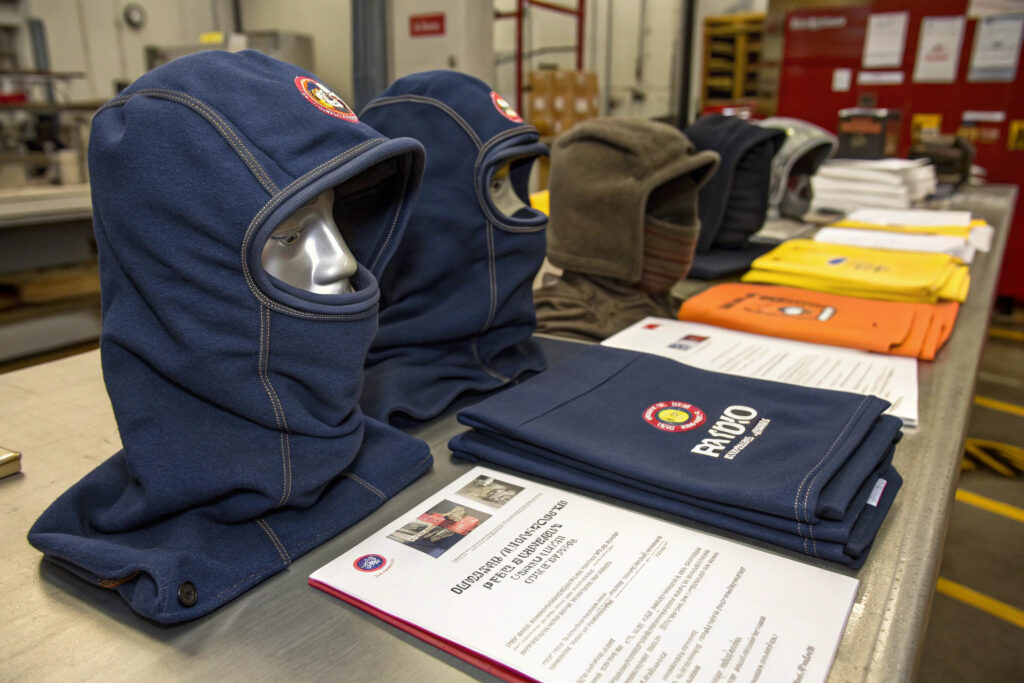

Knowing the standard is one thing; finding a manufacturer who can reliably produce to it is another. The market is split between finished goods brands and specialized manufacturers, each with different advantages for a procurement strategy.

Reliable manufacturers operate in two main tiers: established Western safety brands that sell finished products, and specialized industrial apparel manufacturers, often based in global production hubs like China, which offer greater customization and scalability for bulk procurement. For branded goods, companies like Ariat International offer specific FR balaclava products designed for industrial use. For custom or large-volume needs, turning to industrial manufacturers on platforms like Alibaba can be effective, but requires rigorous vetting.

What should I look for in an industrial manufacturer's profile?

When evaluating manufacturers, go beyond the product listing. First, examine their stated industry experience. A reliable supplier will explicitly list "oil and gas" as a core application for their FR products, indicating an understanding of the sector's needs. Second, scrutinize their material specifications. They should name specific, high-performance FR fibers (e.g., Nomex®, Kevlar®, Modacrylic, FR-treated cotton) rather than just "FR fabric." Mention of partnerships with premier fabric mills (like TenCate) is a strong positive indicator. Third, assess their service capability. Look for evidence of support for small-batch sampling, low Minimum Order Quantity (MOQ), and comprehensive logo or design customization options. This flexibility is crucial for prototyping and building a partnership.

How can I effectively vet a potential supplier before placing an order?

Vetting is a multi-step due diligence process. Start by requesting compliance documentation. Ask for copies of NFPA 2112 or other relevant certification labels and the supporting third-party test reports for the exact product you are considering. Next, order physical samples. Evaluate the sample's construction, stitching quality, label accuracy, and comfort firsthand. Then, audit their quality process. Inquire about their in-house quality control procedures. Do they have dedicated QC staff? What tests do they perform on production batches? Finally, for critical partnerships, consider a factory audit. This could be conducted by a third-party inspection service to verify their production facilities, quality management systems, and social compliance standards. This level of diligence separates true technical manufacturers from simple trading companies.

How Do I Manage Customization and Bulk Supply Logistics?

After identifying a qualified manufacturer, the next challenge is executing a custom order efficiently. This phase turns a prototype into a delivered asset, covering design adaptation, production scaling, and navigating complex international logistics.

Managing customization and bulk supply requires clear technical communication, structured project timelines, and a strategic approach to logistics that accounts for the oil and gas industry's operational realities. A manufacturer that offers integrated services from sample development to final export packing simplifies this process significantly. For example, a supplier that can manage embroidery for company logos, provide multiple color options (including high-visibility yellow for safety), and accommodate low MOQs for initial orders demonstrates the operational agility needed for a successful partnership.

What are the key steps in the customization workflow?

The workflow follows a disciplined sequence. It begins with finalizing the technical pack ("tech pack"), which includes detailed drawings, material specs, size charts, and label/logo artwork. Next is the sampling phase. A professional manufacturer will produce a prototype sample for your approval, which is the time to test fit, function, and compliance. After sample sign-off, you move to bulk production. Here, clear communication on a production schedule with defined milestones (fabric procurement, cutting, sewing, QC, packing) is essential. Finally, logistics and delivery must be planned. For oil and gas projects, which can be in remote locations, you need to decide on Incoterms (e.g., FOB, CIF) and choose between air freight for urgency or sea freight for cost-effective bulk shipments. A partner experienced in exporting to global energy sectors will be invaluable here.

How can I ensure quality consistency in a large bulk order?

Consistency is ensured through process control, not luck. Key strategies include: implementing in-process quality checks (IPQC) where inspectors monitor quality during production, not just at the end; conducting a Defect AQL Inspection on a statistically significant sample of the finished batch before shipment; and using detailed packaging specifications to ensure products arrive undamaged. Furthermore, discuss the manufacturer's policy on fabric lot consistency to avoid color or shade variations within your order. Establishing these protocols upfront with your supplier aligns expectations and protects your investment.

Conclusion

Sourcing FR-rated balaclavas for the oil and gas sector is a technical procurement exercise that balances stringent safety compliance with practical supply chain management. Success hinges on a clear understanding of NFPA 2112 standards, partnering with manufacturers who have proven expertise in high-performance FR textiles, and managing the customization and logistics process with precision.

By following a structured approach—verifying certifications, vetting manufacturers thoroughly, and establishing robust quality control protocols—you can secure a reliable supply of safety-critical equipment that protects your workforce and meets regulatory demands.

If you are looking to develop or source custom FR balaclavas and other protective headwear, Shanghai Fumao Clothing can be your dedicated manufacturing partner. With expertise in functional fabrics and a full-cycle production approach, we support clients from concept through to delivery. For a detailed discussion on your specific requirements, please reach out to our Business Director, Elaine. Contact: Elaine, Business Director. Email: elaine@fumaoclothing.com.