As a restaurant owner or hospitality manager, you're constantly battling staff burnout and workplace injuries. You've probably seen your best chefs suffering from neck and back pain after long hours hunched over a stove, leading to fatigue, costly mistakes, and even staff turnover. What if their uniform could actively help prevent this?

The key to sourcing chef hats with posture-sensing tech is to partner with a manufacturer that has proven expertise in both apparel production and smart textile integration. This involves identifying suppliers who can embed lightweight, durable sensors and haptic feedback modules into the traditional toque, ensuring the final product is not only technologically functional but also comfortable, washable, and compliant with food safety standards.

This might sound like something from a sci-fi movie, but as someone who has been at the forefront of hat manufacturing for over 20 years, I've seen technology transform our industry. We're no longer just sewing fabric; we're weaving innovation into every fiber. The concept of a "smart" chef hat isn't just a novelty; it's the next logical step in creating a safer, more efficient professional kitchen. Let's walk through how you can source this groundbreaking piece of workwear for your team.

Why Is Posture Tech a Game-Changer for Kitchens?

You see the daily grind in your kitchen. Chefs spend hours in strenuous, repetitive positions, leading to chronic pain and a high rate of musculoskeletal injuries. This not only affects their well-being but also impacts your bottom line through sick days, reduced productivity, and workers' compensation claims.

The solution is proactive, real-time feedback. A chef hat with integrated posture-sensing technology provides exactly that. Using lightweight sensors to monitor neck and upper back alignment, the hat can deliver a gentle vibration—a haptic alert—the moment a chef starts slouching. This simple cue encourages immediate self-correction, building muscle memory for better posture over time. Partnering with an innovative manufacturer like Shanghai Fumao Clothing allows you to develop a custom solution that integrates this technology seamlessly into a comfortable, professional-looking uniform.

Let's dive deeper into the tangible benefits of this technology. It's more than just a gadget; it's a strategic investment in your team's health and your kitchen's operational excellence. By turning a mandatory piece of uniform into an active wellness tool, you can create a safer and more sustainable working environment.

How Does It Directly Reduce Workplace Injuries?

The most significant benefit is the reduction of work-related musculoskeletal disorders (MSDs). According to OSHA, these are among the most frequently reported causes of lost or restricted work time. The constant, gentle reminders from a posture-sensing hat help prevent the cumulative strain on the neck, shoulders, and upper back that leads to these injuries. By correcting poor posture in the moment, the technology acts as a preventative measure, rather than a reactive one. Over time, this can lead to a dramatic decrease in injury claims and create a healthier, more resilient kitchen brigade.

Can It Actually Improve Culinary Precision?

Yes, surprisingly, it can. Fatigue and physical discomfort are enemies of precision. A chef suffering from neck strain is more likely to make mistakes, whether in the fine motor skills required for intricate knife work or in maintaining focus during a busy service. By reducing physical strain, the posture-correcting hat helps chefs stay more comfortable and focused for longer periods. This sustained concentration translates directly to higher quality and consistency in food preparation. It's a clear example of how investing in employee wellness can yield tangible operational returns.

What Are the Key Features of a Smart Chef Hat?

You're intrigued by the concept, but you're also a practical business owner. You need to know exactly what you're sourcing. What does this "posture-sensing tech" actually consist of? You're worried about clunky batteries, complicated software, and whether the hat will be too heavy or uncomfortable for a 12-hour shift.

A well-designed smart chef hat should feel almost identical to a traditional one. The technology must be discreet, lightweight, and intuitive. The core features include miniaturized, flexible sensors to detect slouching, a small haptic feedback motor for alerts, and a removable, rechargeable power source. At Shanghai Fumao Clothing, our R&D process for smart apparel focuses on user experience. We ensure all electronic components are seamlessly integrated and easily removable, allowing the hat itself to be laundered just like any other piece of uniform.

Let's break down the essential components and considerations. Understanding the technology inside the hat will give you the confidence to engage with suppliers and specify a product that truly meets the demands of a professional kitchen environment.

What Kind of Sensors Are Used?

The most common sensors used are lightweight accelerometers and gyroscopes, similar to those found in smartphones and fitness trackers. These are typically embedded in a flexible, thin strip placed at the back of the hat's band, near the nape of the neck. The accelerometer measures tilt and orientation relative to gravity. When your head and neck slump forward past a pre-calibrated angle, the sensor detects this change and triggers the alert. The key is sourcing high-quality, miniaturized MEMS sensors that are durable enough to withstand the heat and humidity of a kitchen.

How Is the Hat Powered and Maintained?

Ease of use is critical. The hat is powered by a small, slim lithium-ion battery pack, usually weighing no more than a few grams. This pack is designed to be easily snapped out of a discreet pocket in the hat's band for recharging, typically via a standard USB-C port. A single charge should last for several full shifts. Most importantly, all electronic components—the sensor strip and the battery—are housed in a sealed, removable module. This allows the chef to simply take out the "brains" of the hat before throwing the fabric toque into the laundry, ensuring hygiene standards are easily met. This modular approach to electronic design is fundamental to creating practical smart apparel.

How Do You Source a Reliable Smart Apparel Supplier?

You're ready to explore this innovative product, but your usual suppliers only make traditional apparel. Sourcing a product that merges textiles with electronics feels like stepping into a whole new world. You're concerned about finding a manufacturer who genuinely understands both sides of the equation and can deliver a reliable, certified product without communication barriers or quality control issues.

The key is to look for a supplier with a dedicated R&D department and a proven track record in "functional fabrics" or "smart textiles." A true partner won't just be an assembler; they will have in-house expertise in both garment construction and electronics integration. Ask potential suppliers about their experience with wearable tech, request certifications for their electronic components (like CE and RoHS), and inquire about their quality control process for the finished smart product. A vertically integrated manufacturer like us at Global-Caps, with our own CNAS-accredited lab, can manage this complex process from end to end.

Finding the right partner is the most critical step. Let's outline the specific questions to ask and the green flags to look for to ensure you're partnering with a capable and trustworthy manufacturer.

What Certifications Should I Ask For?

When sourcing a product with electronics, certifications are non-negotiable. For the electronic components, you must demand compliance with international standards. At a minimum, this includes CE marking, which indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area, and RoHS (Restriction of Hazardous Substances), which restricts the use of specific hazardous materials found in electrical and electronic products. For the US market, FCC certification is crucial, as it regulates radio frequency emissions. A reliable supplier will readily provide documentation for these product certifications, giving you assurance of the product's safety and legality.

How Can I Verify Their Manufacturing Capability?

Go beyond the sales pitch. Ask for a virtual or, if possible, an in-person factory tour. Look for a clean, organized production line that has separate, dedicated areas for electronics assembly and textile work. Inquire about their R&D team. How many engineers do they have? Can they show you prototypes of other smart apparel they've developed? A capable manufacturer will be proud to showcase their innovation hub. Furthermore, ask about their testing protocols. Do they have their own testing lab, like our CNAS-accredited facility? A supplier who invests heavily in R&D and in-house testing is a partner who is serious about quality and innovation.

What Is the Customization and Ordering Process?

You've identified a potential supplier, but now you need to turn your concept into a real product. How do you customize the hat to fit your brand's aesthetic? What is the typical timeline from placing an order to receiving it in the U.S.? You're worried about the process being slow and complex, especially with the added layer of technology.

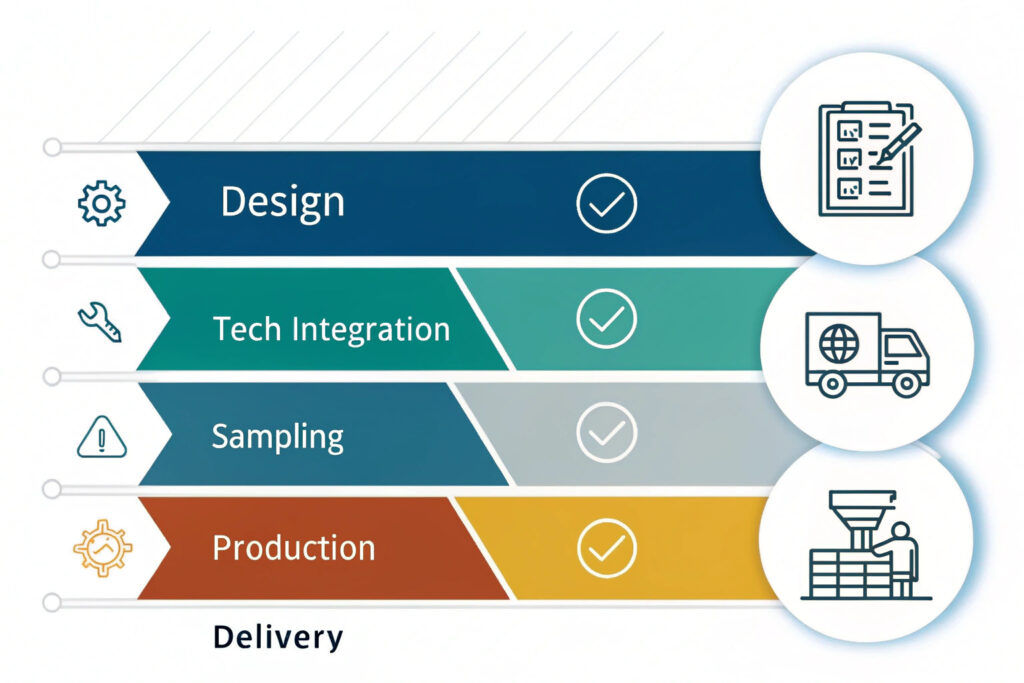

The process for a smart hat is surprisingly similar to that of a traditional garment, with a few key additions. It starts with design and branding. You can customize the hat's color, fabric, and logo placement just as you normally would. The next step is sample development, where the technology is integrated into your custom design. At Shanghai Fumao Clothing, we can turn around a fully functional smart sample in about one to two weeks. Once you approve the sample, we move to bulk production, which includes rigorous quality control for both the textile and electronic elements. Our streamlined logistics ensure a clear path for customs and shipping, providing you with a reliable delivery timeline.

Understanding the step-by-step process will help you plan effectively and manage expectations. Let's walk through the typical journey of bringing a custom smart chef hat to life.

Can the Hat Be Branded with My Logo?

Of course. The hat is still a key part of your uniform and brand identity. We can apply your logo using several methods. High-quality embroidery is the most popular choice for a classic, premium look. We can also create a woven label or a printed logo. The placement is flexible, but it's typically on the front or side of the hat's band, away from the sensor module area at the back. Our design team works with you to ensure your branding is prominent and professional, seamlessly integrating with the hat's design without interfering with its technological function. This commitment to brand integration is crucial for a successful custom product.

What Is the Typical Lead Time for an Order?

For a custom order of smart chef hats, a realistic lead time is approximately 60 to 75 days from order confirmation to delivery in the U.S. This timeline can be broken down as follows: Sample development takes 1-2 weeks. Once the sample is approved, bulk production and electronics integration typically take 30-40 days. This is longer than a standard hat due to the added assembly and testing of electronic components. Finally, quality control, packing, and international shipping take another 20-25 days. We provide a detailed production schedule and real-time tracking through our digital platform, giving you full visibility and control over your supply chain.

Conclusion

In conclusion, sourcing chef hats with posture-sensing technology is no longer a futuristic fantasy but a practical, strategic decision for any modern hospitality business. By focusing on the tangible benefits of injury reduction and improved precision, you can see this is a clear investment in your team's well-being and your kitchen's performance. The key to success lies in finding a manufacturing partner who is fluent in both apparel and electronics, who can provide certified components, and who offers a transparent and efficient production process. By asking the right questions and prioritizing suppliers with proven R&D and quality control capabilities, you can confidently source a product that is innovative, reliable, and perfectly branded for your establishment.

If you are ready to take the next step in elevating your professional workwear and investing in your team's health, we are here to guide you. To discuss developing a custom smart chef hat for your brand, please reach out to our Business Director, Elaine, at elaine@fumaoclothing.com. Let's innovate together.