I've spent more than 20 years in the hat business, and our focus has always been on evolving with technology. We've mastered everything from UV-protective fabrics to moisture-wicking liners. But last week, I had a conversation that marked a new frontier. I was speaking with a procurement manager for a massive construction firm, a practical, no-nonsense guy like my client Ron. He wasn't interested in style or branding. He pointed to a heatwave map on his screen and said, "Elaine, heatstroke is killing our productivity and endangering my crew. A simple hard hat liner isn't enough. I'm hearing about caps with built-in, wearable air conditioning. Is this real, and how do I source a version that's tough enough for a construction site?"

Sourcing caps with wearable air conditioning for construction requires partnering with a manufacturer who can integrate proven thermoelectric cooling (TEC) modules into a durable, hard-hat-compatible liner or cap. The focus must be on safety, durability, battery life, and ergonomic design, ensuring the technology can withstand the harsh realities of a job site while providing tangible, active cooling to prevent heat-related illness.

The challenge is immense. This isn't a consumer gadget. It's a piece of Personal Protective Equipment (PPE). It has to be rugged, reliable, and safe. A flimsy, fan-based "cooling cap" from a gadget website will be destroyed in a day and could even create a safety hazard. At shanghai Fumao Clothing, we're treating this not as a novelty item, but as the next generation of industrial safety gear.

What Is "Wearable AC" Technology?

You've seen the ads for fans that clip onto a hat brim. You're rightfully skeptical. That's not air conditioning; it's just moving hot air around. True wearable AC is a significant technological leap, and it's crucial to understand the difference before you source anything.

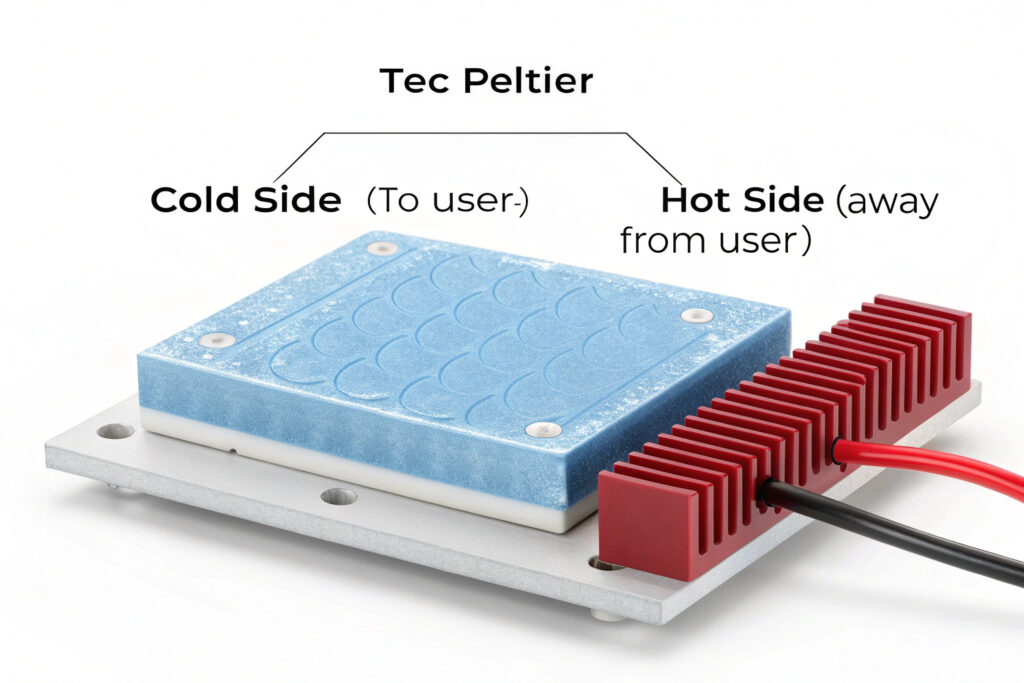

Wearable AC in this context refers to active cooling systems, primarily using Thermoelectric Cooling (TEC) modules based on the Peltier effect. A TEC module is a small, solid-state semiconductor device that, when electricity is passed through it, creates a temperature difference: one side gets cold, and the other side gets hot. The "cold side" is placed against the body, while the "hot side" must be dissipated with a heat sink and a small fan.

When we started prototyping these, the "wow" moment was undeniable. We placed an active TEC module on a desk. One side was frosty to the touch, while the other side became almost too hot to handle. This is the core technology. The engineering challenge isn't the cooling itself; it's how you package it into a wearable, durable, and power-efficient system. It's the same principle used in portable coolers and some high-end car seats, just miniaturized.

Why is this different from evaporative cooling?

Evaporative cooling hats, which you soak in water, are a popular, low-tech solution. However, they have a major flaw: they are only effective in dry, arid climates. In humid conditions, where sweat doesn't evaporate easily, they provide little to no relief and can actually make the wearer feel clammy and uncomfortable.

Wearable AC, because it's an active cooling system, works in any humidity. It doesn't rely on evaporation. It physically pumps heat away from the body. This makes it a far more reliable solution for construction sites in diverse climates, from the humidity of Florida to the dry heat of Arizona.

What are the components of a wearable AC system?

A complete system consists of several key parts that must be ruggedized for construction use:

- The Cooling Cap/Liner: The wearable garment that houses the technology.

- TEC Modules: The solid-state "engines" that do the cooling.

- Heat Sinks & Fans: To dissipate the heat generated by the hot side of the modules.

- Power Source: Typically a rechargeable lithium-ion battery pack.

- Control Unit: To turn the device on/off and adjust the cooling level.

The "Hard Hat Cooler": A Purpose-Built Liner

You can't just stick a cooling module on a regular baseball cap and put a hard hat over it. The design must be integrated with the existing, mandatory safety equipment. The most effective solution is a purpose-built liner.

The "Hard Hat Cooler" is a specialized liner designed to fit comfortably inside a standard construction hard hat, featuring strategically placed cooling modules that target key areas like the temples and forehead, with an external power pack that can be clipped to a belt or harness.

Our design philosophy for this product is safety and ergonomics first. The liner itself is made from a durable, washable, and flame-retardant fabric. All the cooling modules and fans are housed in low-profile, impact-resistant casings. The wire connecting the liner to the battery pack is reinforced and has a quick-disconnect safety feature. Nothing inside the hard hat should interfere with its primary function of protecting the head from impact. This aligns with strict OSHA guidelines on preventing heat-related illness while maintaining PPE integrity.

Where should the cooling modules be placed?

Placement is critical for effectiveness. The goal is to cool blood as it flows to the brain. The most effective locations are:

- The Forehead: A large surface area with significant blood flow close to the skin.

- The Temples: The temporal artery runs close to the surface here, making it a prime spot for heat exchange.

- The Back of the Neck (Optional): While harder to integrate with a hard hat suspension, cooling the back of the neck can have a significant impact on perceived temperature.

What are the power and battery considerations?

This is the biggest hurdle for job site use. A construction shift is 8-12 hours long.

- Battery Life: The system needs to provide at least 4-5 hours of continuous cooling on a single charge.

- Swappable Batteries: The best solution is a system with swappable battery packs, so a worker can easily exchange a depleted battery for a fresh one mid-shift.

- Durability: The battery pack must be housed in a rugged, water-resistant, and impact-resistant case.

- Charging: The system should include a multi-bay charging station so a foreman can charge multiple batteries overnight for the entire crew.

Sourcing Challenge: Finding a Qualified Manufacturer

You won't find a construction-grade wearable AC cap on Alibaba or Amazon. You're looking for a specialized industrial product, not a consumer gadget. Sourcing this requires finding a manufacturer who has proven expertise in both textiles and electronics integration.

A qualified manufacturer for industrial wearable AC must demonstrate expertise in ruggedized electronics, battery safety (UL certification), ergonomic design for PPE integration, and have a robust quality control process for testing both the electronic components and the textile durability.

When a potential client approaches us for this, our conversation is very different. We discuss battery certifications (like UL 2054), Ingress Protection (IP) ratings for water and dust resistance, and our process for stress-testing the wiring and casings. We act less like a hat maker and more like an industrial equipment designer. A qualified partner should be able to speak this language fluently.

What questions should you ask a potential supplier?

- "What is the IP rating of your electronic housings and battery packs?"

- "Are your battery packs UL certified, and can you provide the documentation?"

- "How have you designed the system to integrate with a standard hard hat suspension without compromising safety?"

- "What is your warranty and repair/replacement process for the electronic components?"

- "Can you provide data on the cooling performance (e.g., temperature differential) and battery life under continuous use?"

What is the difference between a prototype and a production-ready unit?

Many small tech companies may have a cool-looking prototype. But a prototype is not a product. The difference lies in:

- Durability: Has it been drop-tested, vibration-tested, and exposed to extreme temperatures?

- Scalability: Can they produce 10,000 units with the same quality and consistency as the first one?

- Certification: Has it passed all the required safety and electronic emissions tests for the target market (e.g., FCC in the US)?

Always ask to see not just the prototype, but evidence of their readiness for mass production.

The Future: Smart, Integrated Cooling Systems

What we're discussing now is the first generation of this technology. The future of job site cooling is even more exciting and will be driven by "smart" technology and data.

The next generation of wearable AC for construction will be "smart" systems that use biometric sensors to automatically adjust the cooling level based on the worker's body temperature and exertion level, optimizing battery life and providing personalized, responsive cooling.

Imagine a liner with a built-in sensor that detects a rise in the worker's skin temperature. It automatically kicks the cooling up a notch. When the worker takes a break in the shade, the system powers down to conserve battery. This data could even be sent to a site foreman's tablet, providing a real-time overview of the crew's heat exposure and allowing for proactive safety interventions. This moves from a simple tool to a full-fledged, data-driven safety platform.

What technologies will enable this?

- Miniaturized Sensors: Tiny, low-power sensors that can accurately measure skin temperature and even heart rate.

- IoT Connectivity: Low-power Bluetooth or LoRaWAN modules that can transmit data from the cap to a central hub.

- Machine Learning Algorithms: Onboard chips that can learn a worker's personal response to heat and optimize the cooling algorithm for them.

How does this improve safety and efficiency?

- Proactive Safety: It can alert a worker or foreman to the risk of heatstroke before symptoms become severe.

- Optimized Battery Life: By only using maximum power when needed, it can significantly extend the operational time of the device.

- Data for Planning: Aggregated data can help construction companies make better decisions about work/rest schedules during heatwaves.

Conclusion

Sourcing wearable AC for construction workers is not about finding a cool gadget; it's about investing in a critical piece of safety equipment. The solution must be an active cooling system, likely based on thermoelectric technology, and it must be engineered from the ground up to be a durable, safe, and ergonomic "Hard Hat Cooler." Finding the right manufacturing partner is a process of rigorous vetting, focusing on their expertise in ruggedized electronics and PPE integration. While the technology is still emerging, its potential to save lives and improve productivity is immense. The future lies in smart, sensor-driven systems that will make job sites safer and more efficient than ever before.

If you are a company looking to pioneer the adoption of this life-saving technology and need a partner who understands the unique challenges of creating industrial-grade wearable tech, my team and I are ready to build it with you. Business Director at shanghai Fumao Clothing, and my email is: elaine@fumaoclothing.com.