Imagine a helmet that not only protects a construction worker's head but also flashes a warning when toxic gas levels rise, or a cap worn by a city commuter that subtly changes color as the PM2.5 concentration climbs. This is the frontier of functional wearables—air quality-monitoring headgear. For manufacturers like us, entering this space means navigating a complex intersection of advanced sensor technology, wearable design, and new market demands.

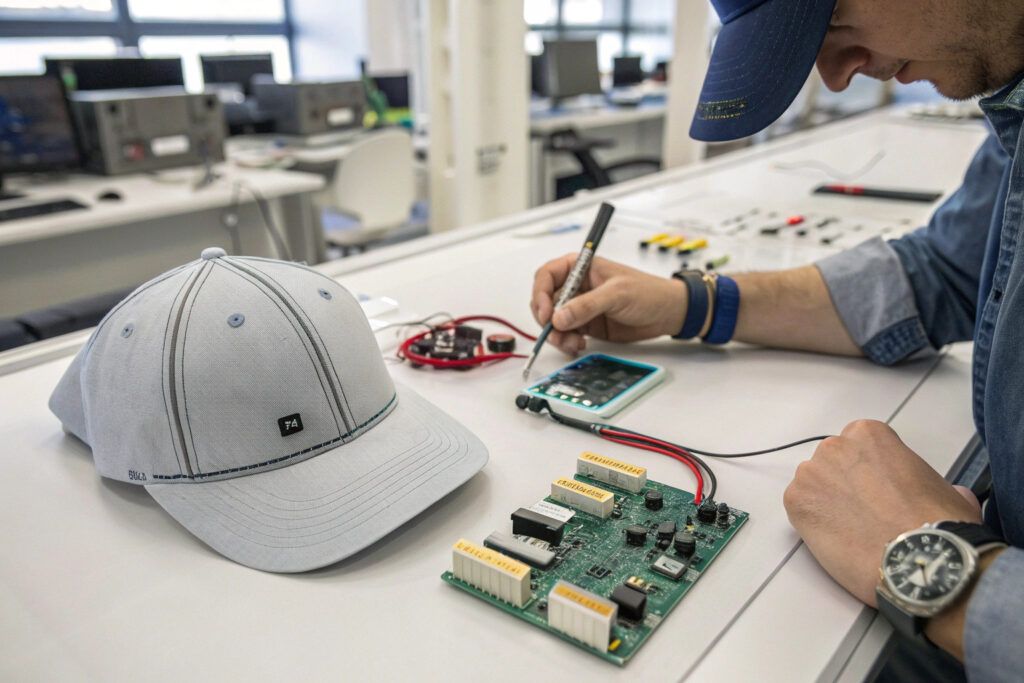

The most viable path to source air quality-monitoring smart caps is through strategic partnerships with sensor technology providers and specialized electronics manufacturers, as ready-made solutions are scarce. Success hinges on integrating miniaturized, low-power sensor modules into cap designs, a process requiring technical collaboration rather than simple off-the-shelf procurement. For a hat manufacturer, this represents a shift from pure apparel production to becoming a tech-integration hub.

At Shanghai Fumao Clothing, while our core expertise is in high-volume hat manufacturing, we recognize that the future of functional headwear lies in such smart integrations. The journey involves understanding the key components, identifying potential partners, and clearly defining your product's purpose. Let's map out a practical sourcing strategy.

What Are the Core Technical Components You Need to Source?

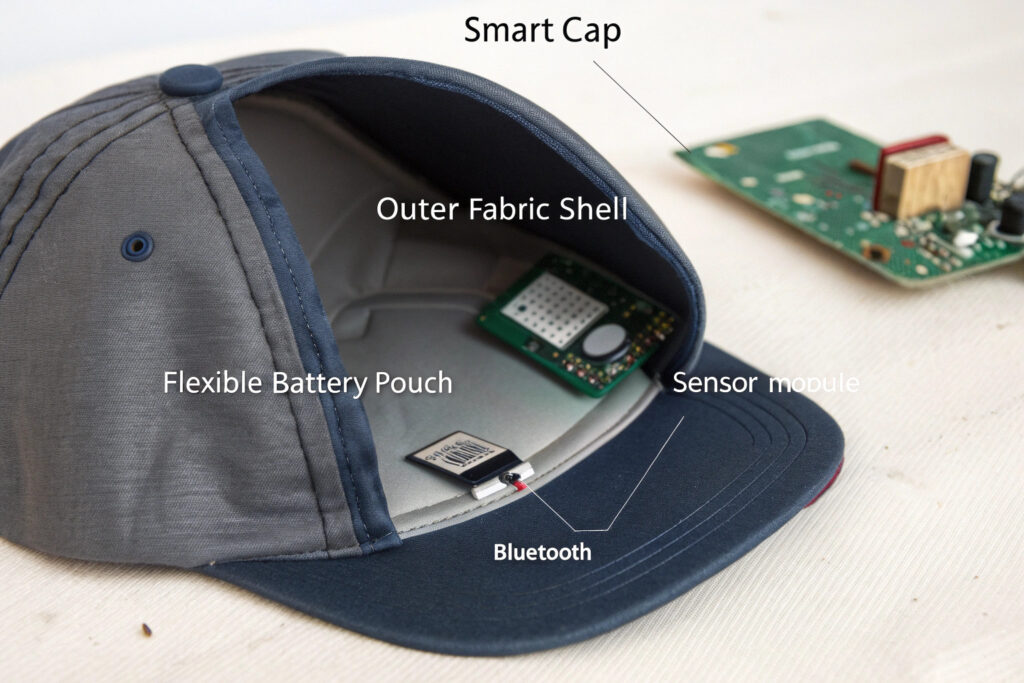

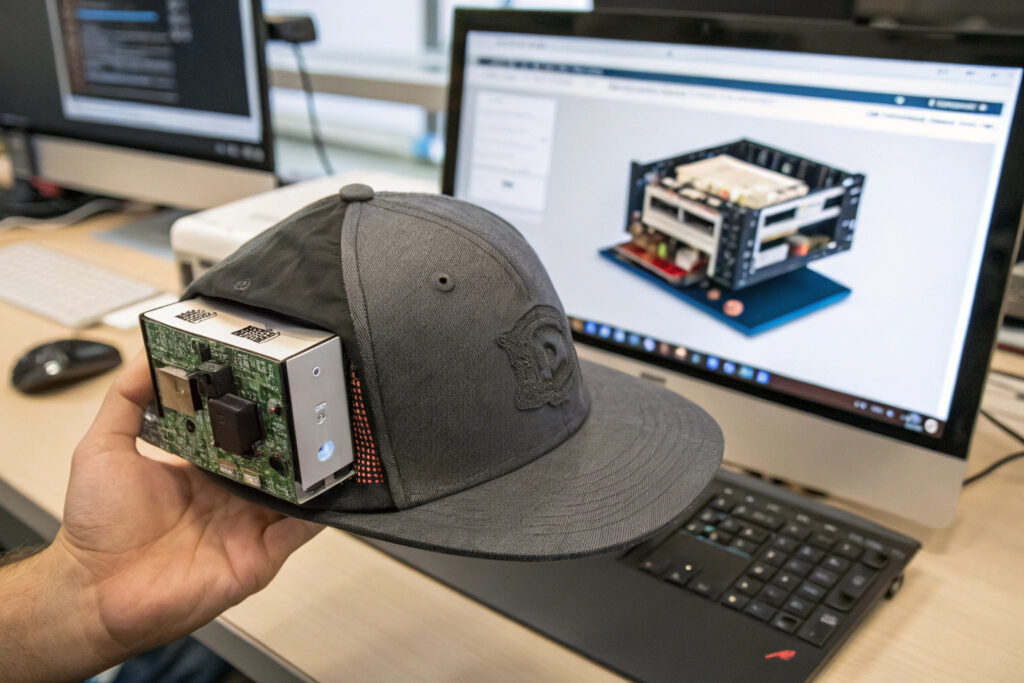

A smart cap is a system, not just fabric. You are essentially sourcing and assembling three critical technological layers: the sensor module, the processing and power unit, and the user interface. Getting these components right is 90% of the battle.

The core of the product is the miniaturized air quality sensor module. This is a highly specialized component that detects specific pollutants. For example, a module like the ZMOD4510 from Renesas is designed for wearable applications and can detect gases like ozone and nitrogen dioxide to calculate an Air Quality Index (AQI). Other critical pollutants to monitor might include PM2.5, carbon monoxide (CO), and volatile organic compounds (VOCs). The choice of sensor dictates what your cap can measure. Accompanying this is a micro-controller to process sensor data, a compact battery solution for all-day wear, and an output method—which could be a tiny LED light, a vibration motor, or a Bluetooth module to sync with a smartphone app.

What Types of Sensors are Used for Different Pollutants?

Not all air quality sensors are the same, and your sourcing will vary by target pollutant. Here’s a quick breakdown of common technologies:

- Metal Oxide (MOx) Sensors: Used in modules like the ZMOD4510 for detecting gases like O3 and NO2. They are small and suitable for wearables.

- Laser Particle Counters: For measuring PM2.5 and PM10. These are more complex but available in miniaturized forms for portable monitors.

- Electrochemical Sensors: Often used for toxic gases like CO and H2S. They are found in industrial safety equipment.

- Non-Dispersive Infrared (NDIR) Sensors: The standard for accurate CO2 measurement, common in indoor air quality monitors.

Your first sourcing call should be to specialized sensor manufacturers or distributors who can provide evaluation kits and integration support.

How Do You Handle Data and User Interaction?

This defines the user experience. A simple, standalone cap might use a color-changing fabric that reacts chemically to pollutants—a concept demonstrated in the "Aerochromics" project where dyes react to CO or particles. However, for precise, quantitative data, you need electronics. The sensor data must be processed, which requires a micro-controller (like an ARM Cortex-M series chip). For output, the simplest is an LED that changes from green to red. For advanced functionality, integrating a low-energy Bluetooth module is key, allowing the cap to transmit data to a companion smartphone app where users can see real-time AQI readings and historical data. Sourcing these micro-electronics requires partners in the consumer electronics or IoT hardware space.

Who Are the Potential Sourcing Partners and Suppliers?

You will not find a factory that produces complete "smart caps" on Alibaba. Building this product requires assembling a consortium of partners, each providing a piece of the puzzle.

Your sourcing network should include specialized sensor manufacturers, flexible electronics assemblers, and IoT solution developers. The goal is to find partners who can provide not just components, but also integration support and firmware/software development.

| Partner Type | What They Provide | Example Companies/Entities (From Search) | What to Ask For |

|---|---|---|---|

| Core Sensor Tech | Miniaturized air quality sensor modules, evaluation boards, technical datasheets. | Renesas (ZMOD4510 module), Companies like ScioSense, Sensirion. | Request samples, evaluation kits, and application notes for wearable integration. |

| Electronics Design & Assembly | Design of the PCB that holds the sensor, micro-controller, and Bluetooth chip. Assembly of these components into a small, flexible package. | IoT hardware design houses, flexible PCB manufacturers. | Inquire about experience with wearable tech, minimum project fees, and ability to create water-resistant enclosures. |

| Firmware & App Development | The code that runs on the cap's chip and the smartphone application for data display. | IoT software studios, freelance developers on platforms like Toptal. | Request portfolios of previous health/wellness wearable apps and ask about data visualization capabilities. |

| Advanced Prototyping | For proof-of-concept, especially for non-electronic solutions like reactive fabrics. | Material science labs, specialty dye/ink manufacturers. | Discuss the feasibility and durability of color-changing textiles for outdoor use. |

Are There Any Existing Products or Patents to Guide Sourcing?

Yes, researching existing concepts is a vital sourcing step. While not mass-market products, they provide a blueprint:

- Research Concepts: Academic papers show prototypes like sensor-embedded smart helmets for detecting toxic gases. This validates the technical feasibility.

- Patent Filings: A Chinese patent exists for a "head-mounted air quality risk warning and improvement device" that integrates biosensors and air quality sensors. Analyzing such patents reveals component layouts and potential supplier names in the documentation.

- Adjacent Products: Companies like ible Tech make wearable air purifiers (like the Airvida), while Oizom makes portable air quality monitors (Polludrone). While not caps, they are benchmarks for miniaturizing sensor technology. Sourcing similar sensor packages from their suppliers could be a strategy.

Haven’t You Considered Professional Winter Gear Brands for Direct Sourcing?

Established outdoor gear brands with a focus on professional winter sports/rescue gear are ideal for reliable, ready-to-customize ski patrol hats—they prioritize performance and compliance with industry safety standards.

What Are the Major Sourcing and Production Challenges?

Bridging the gap between a prototype and a reliable, manufacturable product is where most projects stumble. Anticipating these hurdles is crucial for a realistic sourcing plan.

The primary challenges are achieving a wearable form factor, ensuring power efficiency and battery life, and managing product durability and certifications. Integrating rigid electronics into a soft, flexible, and often sweaty environment like a cap is a fundamental design hurdle. The electronics package must be lightweight, low-profile, and robust enough to handle bending and minor impacts. Furthermore, continuous sensor operation is power-hungry. Sourcing a suitably small yet long-lasting battery (or exploring energy-harvesting options) is a critical task. Finally, the finished product must be washable (or have easily removable electronics), safe for skin contact, and comply with electronic device regulations (FCC, CE).

How Do You Ensure Accuracy and Calibration?

An inaccurate air quality reading is worse than no reading at all. Sourcing sensors is just the start; they require calibration. Professional-grade portable monitors, like the Aeroqual Series 500, emphasize traceable calibration and sensor accuracy[citation:8]. For a consumer cap, you may not need lab-grade precision, but you must source sensors from reputable suppliers who provide calibrated units and have a plan for factory calibration during your assembly process. This adds a step to your quality control protocol that traditional hat manufacturing does not have.

What Does This Mean for Your Supply Chain?

Adopting this product line transforms your operations. You move from a textile-focused supply chain to a dual supply chain. You'll need to manage lead times for electronic components (which can be volatile), establish ESD-safe handling areas in your factory, and develop new testing procedures for both garment quality and electronic functionality. It requires close collaboration between your apparel product development team and new hardware engineering partners—a significant but necessary operational evolution.

Haven’t You Explored Specialized Wearable Tech Platforms & Brands?

Dedicated wearable tech brands and niche platforms are the primary sources for air quality-smart caps, as they focus on merging functionality with user-centric design.

Why Overlook B2B Industrial Suppliers & Custom Wearable Manufacturers?

For specialized use cases (e.g., outdoor workforces, event management, or corporate wellness programs), B2B suppliers and custom manufacturers offer tailored solutions to meet specific needs.

Why Overlook Niche Industrial & Custom Wearable Suppliers?

For specialized use cases (e.g., industrial workplaces, outdoor patrols, or custom team requirements), niche suppliers and custom manufacturers deliver tailored solutions that meet specific environmental or functional needs.

Conclusion

Sourcing air quality-monitoring smart caps is an exercise in technology partnership and integrated design. The path forward is not to find a single supplier, but to strategically source the core sensor intelligence and partner with experts who can help encapsulate that technology into a wearable, comfortable, and useful form factor. It demands a clear vision of the target user (industrial safety vs. consumer wellness), a deep understanding of the technical constraints, and a willingness to navigate a more complex, tech-driven supply chain.

For a forward-thinking manufacturer, this challenge is also a tremendous opportunity to lead in the next generation of functional apparel. It aligns perfectly with a commitment to innovation and high-value product development.

If your brand is ready to explore the development of smart, sensor-integrated headwear, Shanghai Fumao Clothing can be your gateway. We have the headwear manufacturing expertise and are actively building partnerships in the wearable tech space to facilitate this convergence. We can help manage the integration of sourced technology into scalable, high-quality cap designs. To discuss how we can collaborate to turn this innovative concept into a producible reality, please contact our Business Director, Elaine, at elaine@fumaoclothing.com.