Are you struggling to find a hat supplier who can deliver the style, quality, and portability that today's market demands? For fashion brands and retailers, a foldable straw hat represents the perfect blend of seasonal style and practical convenience. However, bringing this seemingly simple product from concept to mass production involves navigating a complex web of design, material science, and manufacturing expertise.

This guide will walk you through the essential process, from structural design and material innovation to efficient assembly, showing you how to successfully produce a high-quality, market-ready foldable straw hat.

Producing a foldable straw hat requires a three-part strategy focusing on innovative structure, specialized materials, and precision manufacturing. First, you need a design that incorporates folding mechanisms, like a nested-layer crown or a brim with a sewn-in elastic ring. Second, you must select and treat materials—such as specific straw weaves or blended fabrics—for both natural aesthetics and durable flexibility. Finally, specialized steps like precise assembly, controlled shaping, and thorough quality control transform these elements into a reliable, portable product suitable for modern retail and consumer use.

The journey from a flat sketch to a hat that can be neatly packed in a beach bag is fascinating. It demands careful attention at every stage to ensure the final product is not only beautiful and functional but also consistently manufacturable at scale. Let’s dive into the specifics.

What Are the Key Design Principles for Foldability?

The foundation of a successful foldable straw hat is its structural design. Unlike a rigid hat, it must have specific engineered features that allow it to collapse without damage and spring back into shape. There are two primary approaches: designing a collapsible crown and creating a flexible, yet shape-retaining, brim.

How Do You Engineer a Collapsible Crown?

One effective method is the layered or nested design. Imagine the crown divided into horizontal sections that can telescope into one another. A historical patent describes a "foldable tower cap" where the pyramidal crown is split into four separate layers. When folded, the upper layers neatly nest inside the bottom layer, drastically reducing the hat's height and volume. This creates a compact, regular shape that is easy to pack. The connection between layers is critical; designs may use integrated flaps or even small, hard rods as connectors to ensure the hat remains a single, stable unit when unfolded for wear. This principle moves beyond simple fabric compression to a predictable, mechanical folding action.

What Makes a Brim Foldable and Durable?

The brim is the most challenging part, as it needs to be wide yet packable. The industry standard involves integrating a thin, elastic metal wire into the outer seam of the brim. To solve the common problem of sharp wire ends damaging fabric, advanced methods use a flat wire rod made by rolling spring steel. This process creates a smooth, oval-shaped wire without sharp edges. The ends are then securely joined inside a small, crushed metal sleeve, forming a continuous, safe ring that is sewn into the brim. This spring-like wire allows the entire brim to be twisted and folded into a small bundle and then snap back to a perfect circle—a feature central to the functionality of foldable sun hats and visors. For more insights on modern hat design principles, organizations like the Headwear Association provide valuable industry resources.

How Do Material Selection and Treatment Impact Foldability?

Choosing the right straw and applying the correct treatments are what transform a good design into a great product. The raw material must possess inherent flexibility, which is then enhanced through controlled manufacturing processes to achieve the perfect balance of hand-feel, durability, and foldability.

Which Straw Types and Weaves Are Best?

Not all straw is created equal for this purpose. The ideal straw material is naturally pliable and fine. Paper straw, wheat straw, and certain finer braided natural straws are excellent choices as they start with a more flexible base than rigid materials like raffia or bamboo. The weave pattern is equally important. A tight, uniform braid provides structural integrity, while a slightly looser or flatter weave can improve flexibility. In some modern interpretations, designers even look beyond traditional straw, using materials like polypropylene rope for its straw-like appearance, modern feel, and inherent weather resistance. For suppliers like us at Shanghai Fumao Clothing, sourcing the right base material is the first critical step in our development process.

What Are the Essential Shaping and Stiffening Treatments?

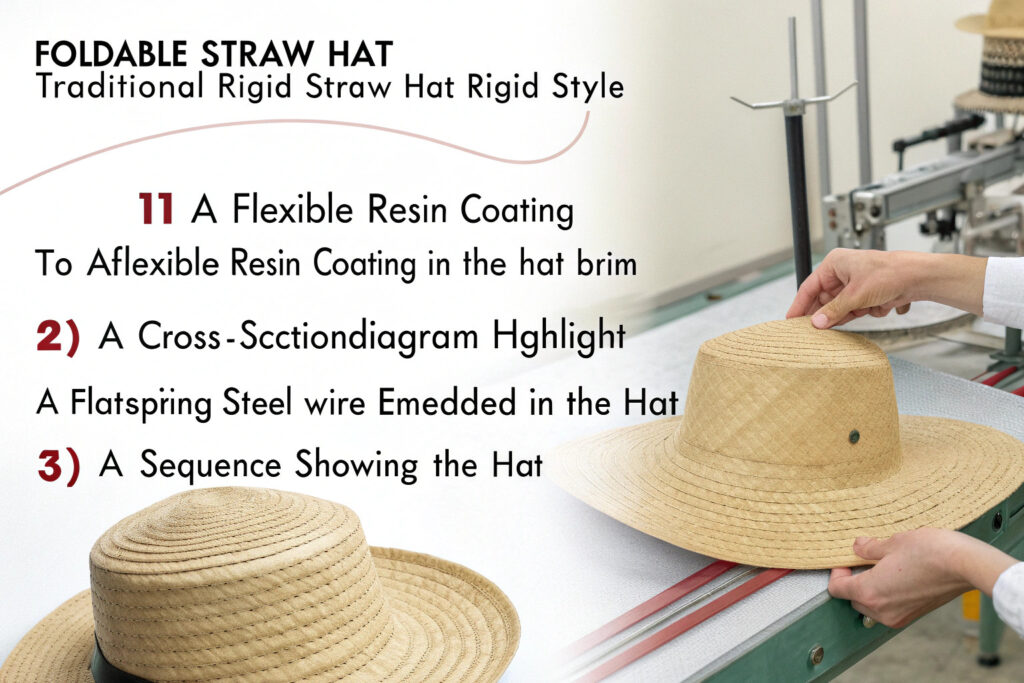

Historically, shaping a straw hat was a slow, manual process involving dipping the hat body in lacquer and air-drying for up to 36 hours—a method prone to imperfections. Modern production for foldable hats uses more controlled techniques. A key step is the application of a flexible stiffening agent or resin. This is often done via a rapid, automated process where hats on a conveyor are dipped, spun to remove excess liquid (preventing streaks and thick spots), and then passed through a heated drying chamber. This controlled drying in minutes, as opposed to hours, sets the shape without making the straw brittle. The goal is not to create a rigid shell, but to give the straw enough "memory" to return to its original form after being folded, which is a specialized treatment we perfect in our own production lines. Understanding the chemistry of these textile finishing processes is key to product performance.

What Does the Specialized Manufacturing Process Look Like?

Transforming flexible straw and clever designs into a consistent, high-quality product requires a dedicated and precise manufacturing sequence. This process builds upon standard hat-making but adds critical steps for foldability and final form.

What Are the Core Assembly Steps?

The process begins with cutting the straw fabric (or pre-woven braid) according to precise patterns for the crown panels and brim. For a nested crown design, each layer must be assembled separately before being connected. The brim assembly is particularly crucial: the spring wire must be accurately measured, joined, and perfectly sewn into its channel around the edge. Any misalignment here will cause the brim to lose its shape. After the main components are sewn, the hat gets its first shaping, often over a mold with gentle steam or heat to set the basic form without locking in rigidity. This stage requires artisans who understand how to handle flexible materials without over-stressing them. The importance of quality control in sewn products cannot be overstated for brand reputation.

How Is the Final Shape Set and Quality Ensured?

The final blocking and setting are what give the hat its retail-ready appearance. The hat is placed on a conforming mold for a final shaping cycle. For materials treated with flexible resin, this step cures the treatment. Rigorous quality control for a foldable hat is non-negotiable and goes beyond standard checks. Every single hat must undergo a functional fold test: it is folded and packed repeatedly to ensure the wire doesn't snap, the seams don't strain, and, most importantly, that it springs back to its perfect shape without permanent creases. As a professional manufacturer, we pair this with checks for even stitching, symmetry, and material flaws to ensure a 98% pass rate before shipment, giving our clients complete confidence in their order's reliability.

What Are the Common Production Challenges and Solutions?

Even with a solid design, moving into bulk production presents specific hurdles. Anticipating these challenges and having proven solutions is what separates a successful product launch from a problematic one.

How Do You Maintain Consistency in a Natural Material?

Straw is a natural, often hand-woven material, which can lead to variations in thickness, color, and flexibility between batches. The first solution is rigorous incoming material inspection, grading straw braids before they enter production. The second is process standardization. Modern techniques, like the automated conveyor-based finishing system, emphasize control. By automating the application and drying of stiffening agents, you remove human variables, ensuring each hat receives the same amount of treatment for uniform flexibility and durability. This principle of controlled, repeatable processes is central to how we manage quality at scale for our clients at Shanghai Fumao Clothing.

How Do You Balance Flexibility with Structural Integrity?

This is the core engineering challenge. A hat that's too stiff won't fold; one that's too floppy won't hold its shape. The solution lies in precise calibration at multiple points:

- Wire Specification: The gauge, temper, and exact alloy of the brim wire must be calculated to provide the ideal spring force.

- Resin Formulation: The concentration and type of flexible resin used must be tailored to the specific straw.

- Stitch Engineering: Seam construction, thread type, and stitch density in high-stress areas (like where the brim meets the crown) must be reinforced for repeated folding cycles.

Getting this balance right requires an iterative prototyping phase, where samples undergo accelerated life-cycle folding tests. The data from these tests informs fine-tuning before any bulk fabric is cut, safeguarding your investment and timeline. Familiarity with ASTM International standards for textile durability can guide these testing protocols.

Conclusion

Successfully producing a foldable straw hat is a sophisticated process that intertwines thoughtful design, smart material science, and precision manufacturing. It moves far beyond traditional millinery, requiring solutions for mechanical folding, controlled flexibility, and durability under repeated use. By understanding the principles of nested structures, spring-wire brims, specialized straw treatment, and rigorous functional testing, you can develop a product that perfectly meets the modern demand for portable, stylish, and reliable headwear.

If you are looking for a partner who not only understands these complexities but has the expertise and supply chain to execute them flawlessly at scale, we should talk. For a detailed discussion on developing and manufacturing your foldable straw hat line, please contact our Business Director, Elaine. Her email is elaine@fumaoclothing.com. Let's transform your vision into a bestselling reality.