As a brand owner or product developer specializing in summer headwear, you know that a straw hat is the epitome of effortless style. But you also know the single point of failure that can turn a beautiful product into a customer complaint: a weak or detaching brim. A customer's idyllic beach day is ruined if the last row of braid on their hat unravels or the brim starts to separate from the crown. This isn't just a minor flaw; it's a catastrophic failure of the product's core structure.

To ensure the brim of a straw hat is securely connected, you must focus on three critical areas of manufacturing: 1) The quality and tension of the sewing thread used, 2) The skill of the sewing machine operator in achieving a consistent, overlapping stitch, and 3) The finishing technique used to terminate the final row of straw braid, which must be securely back-tacked and locked.

I've been manufacturing hats for over two decades at Shanghai Fumao Clothing, and I can tell you that the art of making a durable straw hat lies entirely in the stitching. Unlike a fabric hat where you join two pieces of material, a braided straw hat is built row by row in a continuous spiral. The connection between the crown and the brim—and between each row of the brim itself—is created entirely by the thread. A failure in that thread or stitch is a failure of the entire hat. Let's dive into the technical details that separate a well-made straw hat from one that will fall apart.

Why Is the Sewing Process the Heart of a Straw Hat's Strength?

Most high-quality straw hats are not woven in one piece. They are constructed from a long, continuous braid of material (like raffia, wheat straw, or paper straw). This braid is fed into a specialized, heavy-duty sewing machine, and the operator skillfully guides it in a spiral, stitching each new row to the one before it.

The connection between the brim and the crown isn't a separate step; it's a seamless continuation of this spiral process. The point where the hat transitions from the vertical walls of the crown to the horizontal plane of the brim is the area under the most structural stress. A secure connection here is entirely dependent on the stitch quality, thread strength, and operator skill.

!

How Critical Is the Choice of Thread?

The thread is the skeleton of the hat. If it fails, everything falls apart. Using standard apparel thread is a recipe for disaster. A durable straw hat requires a high-tensile strength, bonded polyester or nylon thread. "Bonded" means the thread is coated with a special resin that prevents the filaments from fraying or shredding as they pass through the tough, abrasive straw material at high speed. This bonding also adds a degree of water resistance and UV protection to the thread itself, preventing it from becoming brittle and weak over time. When specifying a hat, you must insist on this type of industrial-grade thread.

Why Is Operator Skill Non-Negotiable?

Manufacturing a straw hat is not a fully automated process; it's a craft that relies on the "feel" and experience of the machine operator. This is especially true at the critical transition from the crown to the brim. The operator must manually change the angle of the hat to create the flare of the brim, all while maintaining perfect stitch tension and overlap. This is a skill that takes years to master. When vetting a manufacturer, you should always ask about the experience level of their straw hat sewing operators. This human element is a crucial component of quality control in this specific industry.

How Do You Secure the Final, Outer Edge of the Brim?

The outer edge of the brim is the most vulnerable point of the entire hat. This is where the continuous braid terminates. If this end is not properly secured, the hat will begin to unravel from the outside in.

The solution is a combination of secure termination stitching and edge reinforcement. The raw end of the straw braid must be folded under and then stitched over multiple times to lock it in place. This is often done with a "back-tack" or a dense bar-tack stitch. For added durability, many high-quality hats also feature a reinforced edge.

What Is a "Wired Brim"?

One of the best methods for both securing the edge and adding functionality is to sew a thin, flexible wire into the final row of the brim. This is called a wired brim. The wire is encased in the final stitch, providing a rigid structure that the last row of straw can be anchored to. This not only prevents unraveling but also allows the wearer to shape the brim to their liking—a huge selling point. The wire must be rust-resistant (e.g., plastic-coated or stainless steel) to prevent it from staining the straw if it gets wet.

How Does Edge Binding Work?

Another common and very durable method is to finish the brim with fabric edge binding. This involves wrapping the raw outer edge of the brim with a strip of fabric (like cotton twill or grosgrain ribbon) and stitching it in place. This technique completely encases the raw end of the straw braid, making it impossible for it to unravel. It also provides a clean, finished look and can be used as a design element, adding a pop of color or pattern to the hat.

How Can You Verify the Connection Strength Yourself?

When you receive a pre-production sample, you need to physically test the strength of the brim connection before you approve the bulk order. You don't need a lab for this; a few simple, hands-on tests can tell you a lot about the construction quality.

Your goal is to apply targeted stress to the hat's weakest points: the crown-to-brim transition and the outer edge. A well-made hat will withstand this stress without any signs of separation or damage.

What Is the "Seam Pull Test"?

Grip the hat firmly with one hand on the crown and the other hand on the brim, right next to the main seam. Now, pull your hands apart with firm, steady pressure. Don't try to rip it in half, but apply a realistic amount of force. On a poorly made hat, you will see the stitch line stretch, and gaps will appear between the rows of straw. On a well-made hat, the seam will feel solid and unyielding, like a single piece of material.

How Do You Check the Brim Edge?

Find the spot on the outer edge of the brim where the last row of braid was terminated. It's usually a slightly thicker, stiffer area. Pick at it with your fingernail and try to unfold the end of the braid. On a poorly finished hat, you'll be able to easily lift the raw end. On a properly finished hat, it will be so securely stitched down that you can't get it to budge. If it has a wire, bend it back and forth a few times to ensure the wire feels secure and doesn't poke through the stitching.

What Should You Specify in Your Tech Pack?

To ensure the factory produces a durable hat every time, you must provide them with clear, unambiguous instructions in your technical specification sheet, or "tech pack." This document translates your quality expectations into concrete manufacturing requirements.

Your tech pack should include specific callouts for the thread, stitch, and finishing techniques you require. This leaves no room for the factory to cut corners by using cheaper materials or rushing the process.

How Do You Specify the Stitching?

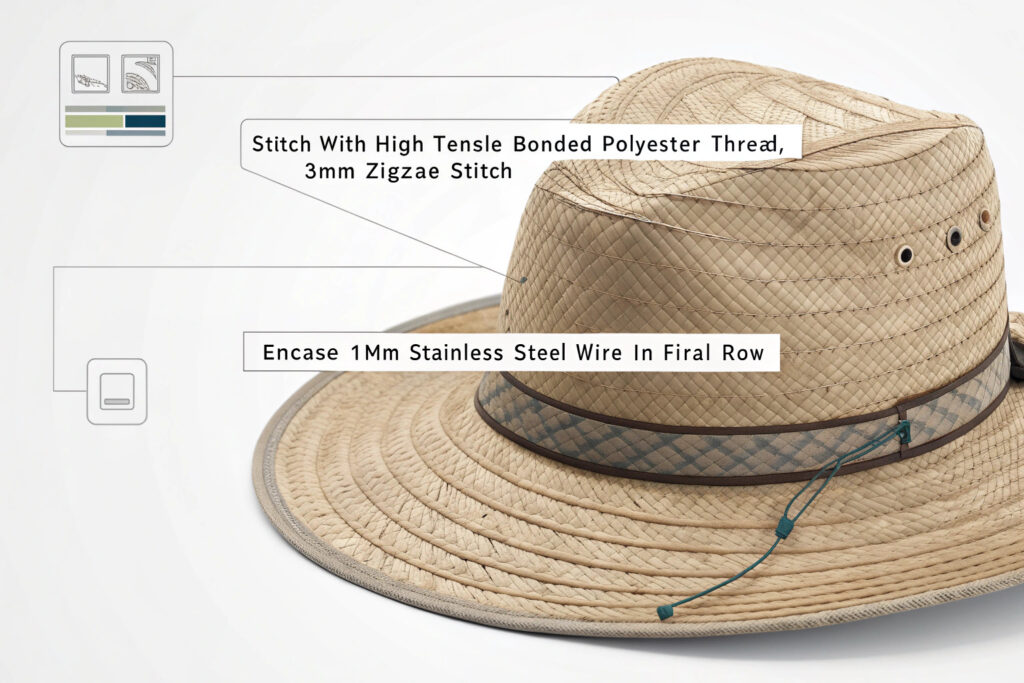

Don't just say "sew the hat." Be specific. Your tech pack should state:

- Thread Type: "Must use high-tensile, bonded nylon or polyester thread, Tex 60 or higher."

- Stitch Type: "Use a 3mm zigzag stitch (or lockstitch)."

- Stitch Density: "8-10 stitches per inch."

- Braid Overlap: "Maintain a minimum of 30% overlap between braids."

How Do You Specify the Finishing?

Clearly define how the brim edge should be finished.

- For a Wired Brim: "Encase a 1mm plastic-coated, rust-proof wire within the final row of the brim. Secure end of braid with a 1cm back-tack stitch."

- For a Bound Edge: "Finish brim edge with a 2cm wide cotton twill binding, folded over and secured with a lockstitch."

Conclusion

The security of a straw hat's brim is not a matter of luck; it is the direct result of deliberate, high-quality manufacturing choices. A strong, secure connection is achieved through the synergistic combination of high-strength bonded thread, a consistent, overlapping stitch applied by a skilled operator, and a meticulously finished and reinforced outer edge. By understanding these critical components, performing your own physical tests on samples, and clearly defining your requirements in a technical pack, you can ensure that every hat you sell is a durable, reliable product that your customers will love for many summers to come.

If you are looking for a manufacturing partner who understands this level of detail and is committed to crafting high-quality, durable straw headwear, my team has the expertise and the passion to deliver. Please contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your next collection.