Creating comprehensive tech packs is the foundation of successful hat manufacturing. Many designers struggle with incomplete specifications that lead to production errors, cost overruns, and timeline delays. A well-developed tech pack serves as the universal language between design vision and manufacturing execution.

Developing custom tech packs for hat designs requires systematic documentation of materials, measurements, construction details, and quality standards. The most effective tech packs combine visual specifications, technical drawings, material requirements, and precise measurements that leave no room for interpretation during manufacturing.

Mastering tech pack development ensures your hat designs translate accurately from concept to finished product while maintaining quality control and cost efficiency throughout production.

What Essential Components Make a Complete Tech Pack?

A comprehensive tech pack serves as the manufacturing blueprint, containing all necessary information to produce hats exactly as designed. Missing elements can lead to costly errors and production delays.

Complete tech packs include technical drawings, materials specifications, measurement charts, construction details, and quality standards that collectively provide manufacturers with unambiguous production instructions.

How to Create Accurate Technical Flats and Drawings?

Technical drawings form the visual foundation of tech packs, providing manufacturers with clear, scaled representations of the hat design from multiple angles.

Professional technical flats should include orthographic projections showing front, back, side, and top views with consistent scale and proportion. Use CAD software or specialized fashion design tools to create precise digital flats that maintain accurate proportions. Include exploded views for complex constructions showing how different components assemble. All drawings should specify scale ratio and include reference dimensions for key features. Our technical packs incorporate 3D renderings when possible to provide additional visual context for complex shapes and constructions.

What Material Specifications Ensure Consistency?

Detailed material specifications prevent substitutions and ensure consistent quality across production runs by providing unambiguous material requirements.

Comprehensive material specs include fiber content percentages, fabric weight, construction type, and finish requirements. Specify color standards using Pantone TPX or TCX codes for exact color matching. Include performance requirements such as UPF ratings, water resistance, or stretch recovery where applicable. Provide approved mill sources or material standards that manufacturers must meet. Our tech packs include physical swatches when possible and always specify testing requirements for material verification.

How to Specify Measurements and Grading?

Precise measurements and consistent grading ensure proper fit and proportional scaling across size ranges. Incomplete measurement specifications represent a common source of production errors.

Comprehensive measurement specifications include point-to-point dimensions, tolerance ranges, and graded specifications that maintain design proportions across all sizes.

What Critical Measurements Ensure Proper Fit?

Key measurements determine how hats fit and function, with specific points varying by hat style and construction type.

Essential measurements include head circumference at multiple depths, crown height, brim width, and brim drop. For structured hats, specify crown tip to front and crown tip to side measurements. Include sweatband dimensions and opening specifications for adjustable features. Our tech packs provide measurement points diagrams with clear visual indicators showing exactly where each measurement should be taken. All measurements specify tolerance ranges - typically ±¼ inch for circumference measurements and ±⅛ inch for critical dimensions.

How to Develop Accurate Size Grading?

Size grading systematically scales measurements across different sizes while maintaining design proportions and functional fit.

Establish a grading rule base with consistent increment steps between sizes - typically ½ inch for head circumference in adult sizes. Use computer-aided grading systems or manual grading techniques that maintain proportional relationships. Specify which points remain fixed versus which points grade between sizes. Our tech packs include graded measurement charts showing exact specifications for each size and grading verification samples to confirm proportional scaling. For international markets, include size conversion charts referencing different regional sizing systems.

How to Detail Construction and Assembly Methods?

Construction specifications determine how hat components assemble into finished products, affecting both aesthetics and durability. Clear assembly instructions prevent manufacturing variations.

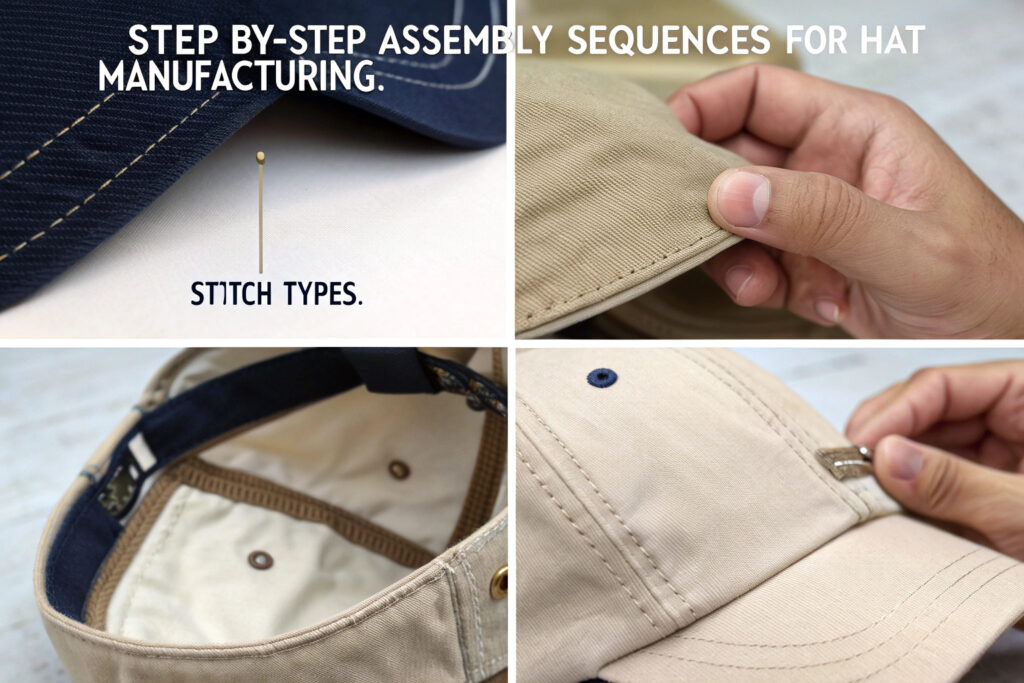

Detailed construction specifications include stitching requirements, assembly sequences, reinforcement methods, and finishing techniques that ensure consistent manufacturing quality.

What Stitching Specifications Ensure Durability?

Stitching details significantly impact hat durability, appearance, and production efficiency, requiring precise specification of techniques and materials.

Specify stitch types using ASTM classification - lock stitch (301), chain stitch (401), or overlook (504) - for different construction areas. Define stitch density in stitches per inch - typically 8-12 SPI for most hat constructions. Specify thread types and weights appropriate for different materials and stress points. Include reinforcement stitching requirements at high-stress areas like crown joins and brim attachments. Our tech packs provide stitch specification diagrams showing exact stitch locations, types, and densities for each construction area.

How to Specify Assembly Sequences?

Proper assembly sequences ensure efficient manufacturing and consistent quality by guiding manufacturers through logical construction steps.

Detail component preparation steps like blocking, fusing, or edge finishing. Specify assembly order - typically constructing crown components first, then adding brim and finishing elements. Include pressing requirements at each stage to maintain shape and appearance. Define quality check points throughout assembly to catch issues early. Our tech packs use flowchart diagrams to visualize assembly sequences and checkpoint specifications to ensure consistent quality at each stage.

What Quality Standards and Testing Should Be Included?

Quality standards and testing requirements ensure finished hats meet design specifications and performance expectations, preventing customer dissatisfaction and returns.

Comprehensive quality specifications include inspection criteria, performance testing, and compliance requirements that verify product quality and regulatory compliance.

How to Define Visual Quality Standards?

Visual quality standards establish acceptance criteria for appearance, workmanship, and finishing that determine whether products meet quality expectations.

Specify acceptable defect levels for issues like stitching irregularities, fabric flaws, or color variations. Define workmanship standards for elements like seam neatness, edge finishing, and component alignment. Include reference samples or photographic standards showing acceptable and unacceptable examples. Our tech packs incorporate AQL sampling plans based on ANSI/ASQ Z1.4 and provide detailed inspection guidelines for consistent quality evaluation.

What Performance Testing Ensures Product Durability?

Performance testing verifies that hats meet functional requirements and durability expectations under real-world use conditions.

Specify fabric testing for colorfastness, dimensional stability, and strength properties. Include construction testing for seam strength and component attachment. Define product testing for elements like shape retention and water resistance. Our tech packs reference specific test methods and performance standards with clear acceptance criteria for each requirement. We also specify testing frequency - typically first article, pre-production, and production lot testing.

How to Organize and Present Tech Pack Information?

Effective organization and presentation ensure manufacturers can easily understand and implement tech pack specifications, reducing errors and communication challenges.

Well-organized tech packs use consistent formatting, clear hierarchies, and logical information flow that guide manufacturers through specifications efficiently.

What File Organization Systems Work Best?

Structured file organization ensures all tech pack components remain connected and accessible throughout the manufacturing process.

Use consistent naming conventions that include style numbers, revision dates, and component identifiers. Create master folders with subfolders for technical drawings, materials, measurements, and quality standards. Implement version control systems to track revisions and prevent confusion. Our standard organization includes PDF master files for easy distribution and native source files for manufacturer modifications.

How to Ensure Clear Communication with Manufacturers?

Effective communication strategies prevent misunderstandings and ensure manufacturers can easily implement tech pack specifications.

Use universal technical terms rather than colloquial descriptions for materials and processes. Include visual references like callout numbers on drawings that correspond to specification tables. Provide translated versions for non-English speaking manufacturers when necessary. Our tech packs include contact information for technical questions and revision history logs to track specification changes and updates.

Conclusion

Developing comprehensive tech packs for hat designs requires meticulous attention to materials, measurements, construction details, and quality standards. The most effective tech packs serve as complete manufacturing blueprints that leave no room for interpretation while facilitating efficient communication between designers and manufacturers.

By implementing systematic tech pack development processes and including all essential components, designers can ensure their hat concepts translate accurately into finished products that meet quality expectations, fit requirements, and design specifications.

Ready to develop professional tech packs for your hat designs? Contact our Business Director Elaine today to discuss technical specification development and manufacturing preparation. Her email is elaine@fumaoclothing.com. Let's create comprehensive tech packs that ensure your hat designs manufacture exactly as envisioned with consistent quality and precise execution.