Imagine you're out on the water—kayaking, paddleboarding, or sailing. The sun is beating down, so you're wearing a cap. Suddenly, you're in the water. In that disorienting moment, what if the cap you were wearing for sun protection could also be the first thing that helps save your life? This is the powerful concept behind a PFD-integrated cap.

Designing a Personal Flotation Device (PFD)-integrated cap is a complex safety engineering project, not just a fashion design exercise. The process requires integrating a compact, user-activated inflation mechanism (like those in inflatable life vests) into a secure, water-sport-specific cap, followed by rigorous testing and certification to meet maritime safety standards. This is about creating a dual-function piece of life-saving equipment.

As the owner of Shanghai Fumao Clothing, my two decades in the headwear industry have been about pushing the boundaries of what a hat can be. The idea of integrating a life-saving device into our core product is the ultimate expression of functional design. It's a project where the stakes are incredibly high, and the margin for error is zero. Let's explore the engineering, design, and rigorous process required to bring such a product to life.

Is This a PFD or Just a Hat? Understanding the Concept

First, let's be crystal clear: this is not a hat that is inherently buoyant. You can't just sew foam into a cap and call it a PFD. A PFD-integrated cap is a manually-activated, inflatable life-saving device that is housed within the structure of a cap.

The core concept is based on the technology used in inflatable life vests and airline life jackets:

- Housing: The cap itself is designed with hidden, reinforced compartments, typically in the crown or along the sides.

- Inflatable Bladder: A compact, folded nylon bladder (the part that fills with air) is packed into these compartments.

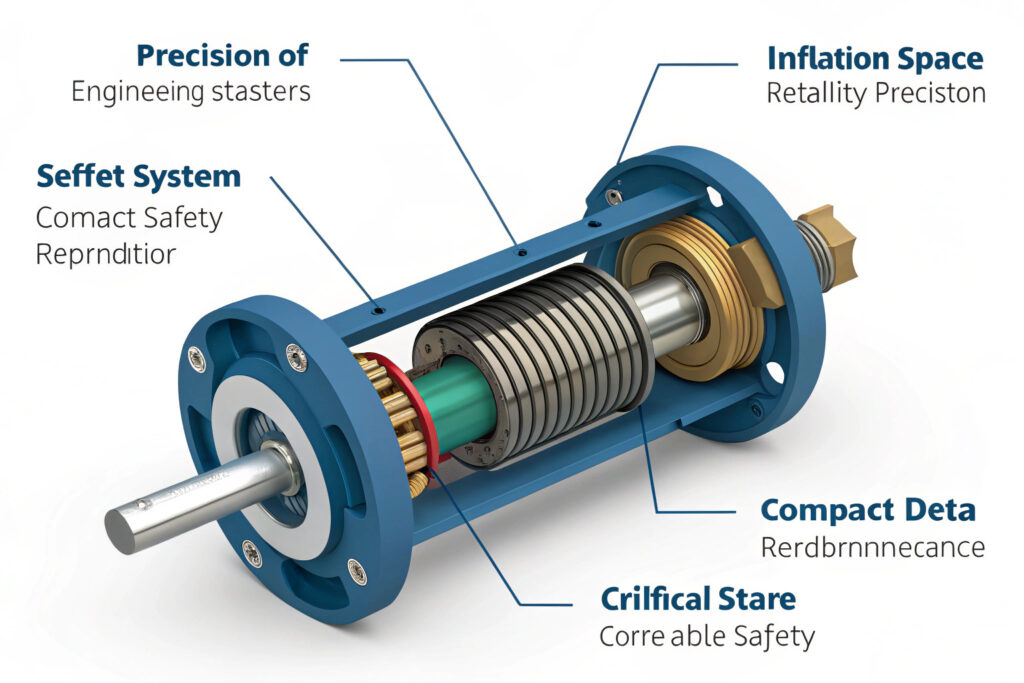

- Inflation Mechanism: A small, threaded CO2 cartridge is connected to the bladder via an inflator mechanism.

- Activation: A manual pull-cord (the "jerk tab") is discreetly integrated into the cap, often tucked under the brim or along the side. When the wearer pulls this cord, it punctures the CO2 cartridge, instantly inflating the bladder.

The inflated bladder would then provide immediate, crucial buoyancy around the wearer's head, helping to keep their airway clear of the water in the critical first moments of an emergency. This is not a replacement for a full life vest, but a supplementary safety device for in-water emergencies. The design must prioritize reliability and safety above all else.

Is this meant to replace a traditional life vest?

No, absolutely not. This would be classified as a Type III or Type V PFD under U.S. Coast Guard regulations, meaning it's intended for specific activities and situations where a bulkier vest might not be worn. It's a supplementary device designed to provide instant, head-up flotation for a conscious person. It's for that "oh no" moment, giving you buoyancy while you get your bearings. Users should always comply with local regulations regarding PFDs, as explained by safety organizations like the BoatUS Foundation.

Has this been done before?

Yes, the concept exists, though it is a very niche market. There have been several attempts and patents for headwear-based flotation devices. For example, products like the "De-Fender" have explored this space. However, bringing a reliable, comfortable, and certified product to the mass market remains a significant engineering and manufacturing challenge.

How Do You Engineer the Inflation Mechanism?

This is the heart of the product, and it must be flawless. The engineering of the inflation system is a life-or-death matter. It involves sourcing and integrating proven, reliable components into a very small space.

The key engineering challenges are:

- Component Sourcing: You cannot invent this from scratch. You must use a proven, certified inflator mechanism from a reputable supplier that specializes in life vest components. Companies like Halkey-Roberts or UML (United Moulders) are the industry standard. Their mechanisms are trusted by the world's best life vest manufacturers.

- Miniaturization and Integration: The challenge is to take one of these mechanisms and integrate it into the cap's design without it being bulky, uncomfortable, or prone to accidental activation. This requires clever pattern engineering and creating reinforced pockets to hold the CO2 cartridge and inflator securely.

- Activation Cord Design: The pull-cord needs to be easily accessible in an emergency but also secure enough that it won't get snagged and accidentally deploy during normal activity. This involves designing a specific channel and a breakaway "tuck" for the cord's handle.

- Bladder Design and Packing: The inflatable bladder must be designed to inflate outward and away from the wearer's head, not inward. It must be folded in a very specific, prescribed way (like a parachute) to ensure it deploys reliably every single time.

At my company, Shanghai Fumao Clothing, this is where our role would shift from apparel designer to technical integrator. We would partner with a certified PFD component supplier and work with their engineers to build the cap's "chassis" around their proven inflation "engine." This is a non-negotiable, safety-first approach to choosing the right materials.

What size CO2 cartridge is needed?

The size of the CO2 cartridge (measured in grams) determines the volume of the inflation and thus the amount of buoyancy. For a headwear device, a small cartridge (e.g., 12-18 grams) would likely be sufficient to provide the necessary buoyancy to keep a person's head above water. The exact size would be determined through extensive testing to meet the buoyancy requirements of the target safety standard (e.g., ISO 12402).

Can the device be repacked and reused?

Yes. Just like an inflatable life vest, after deployment, the user would deflate the bladder, screw in a new CO2 cartridge, and carefully re-fold and pack the bladder according to the manufacturer's instructions. The product would be sold with a "re-arming kit" containing a new cartridge and any necessary safety clips.

What Materials Are Used for the Cap and Bladder?

The materials for this product must be chosen for extreme durability, water resistance, and reliability. This is not a place for standard cotton or fashion fabrics.

For the Cap (The "Chassis"):

- Outer Shell: The cap itself should be made from a lightweight but incredibly strong and abrasion-resistant fabric, such as a ripstop nylon or a high-density polyester. This fabric needs a strong DWR (Durable Water Repellent) finish to shed water and dry quickly.

- Liner: The inside of the cap should have a comfortable, moisture-wicking liner to manage sweat during normal wear.

- Hardware: All components, like the closure system, must be marine-grade. This means using stainless steel or high-impact, UV-resistant polymers that will not corrode or degrade in a saltwater environment. A plastic snapback would be replaced with a secure, non-slip buckle system.

For the Inflatable Bladder:

- Fabric: The bladder is made from a specialized 200-denier or 400-denier nylon fabric that has been coated with polyurethane (PU) on the inside.

- Seams: The seams of the bladder are not sewn. They are RF (Radio Frequency) welded or heat-sealed. This process melts the PU coating on the two pieces of fabric together, creating a permanent, airtight, and waterproof bond that is stronger than the fabric itself. This is the same technology used to make high-end inflatable boats and life rafts.

Sourcing these materials requires a supply chain that is geared towards life-saving and marine equipment, not just apparel. The fabric for the bladder, for example, must come from a certified mill that can guarantee its airtight properties. This is a critical part of the design and certification process.

What is RF welding?

Radio Frequency (RF) welding, also known as dielectric sealing, uses high-frequency electromagnetic energy to heat and melt thermoplastic materials (like PU coatings) at a molecular level. As explained by experts in industrial technology like Thomasnet, this creates a seamless, incredibly strong bond without the need for any external heat or adhesives. It is the gold standard for creating airtight and watertight seams.

Why is ripstop nylon a good choice for the outer shell?

Ripstop nylon has a special reinforcing technique that makes it resistant to tearing and ripping. During weaving, thick reinforcement threads are interwoven at regular intervals in a crosshatch pattern. This texture stops a small tear from spreading. It's a lightweight yet very durable fabric, making it ideal for outdoor and marine gear.

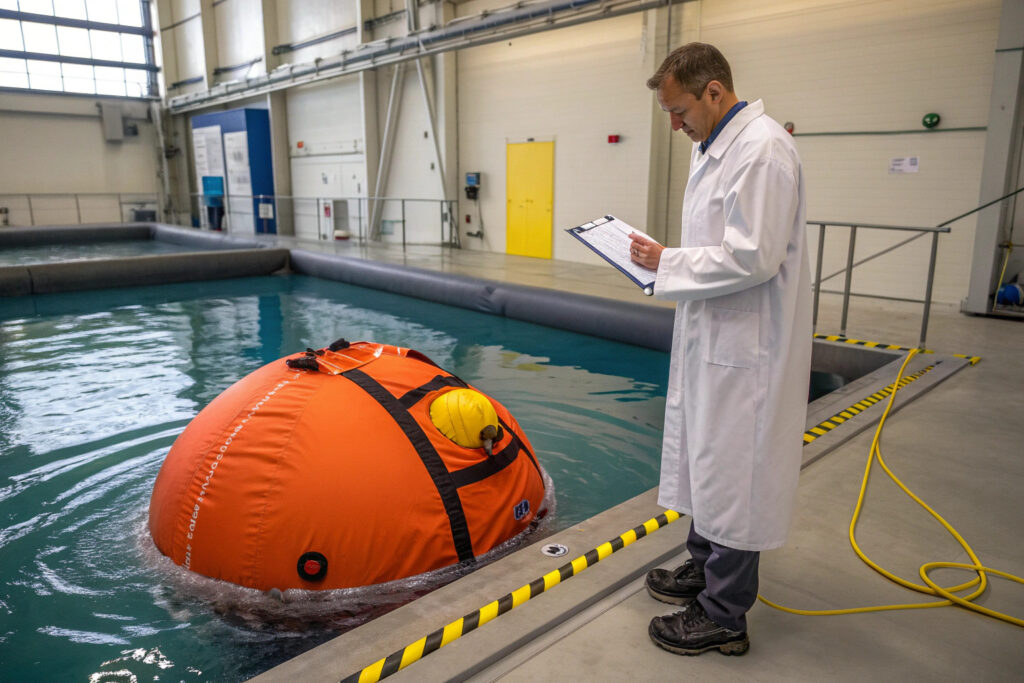

How Do You Get Such a Product Certified?

This is the most important and most challenging step. You cannot sell a product and claim it has life-saving properties without it being officially tested and certified by a recognized regulatory body. An uncertified product is a massive liability and a danger to your customers.

The certification process is rigorous and expensive:

- Identify the Standard: You must first determine which safety standard you are targeting. In the U.S., this would be a specific U.S. Coast Guard (USCG) standard under 46 CFR 160. In Europe, it would be an ISO standard (e.g., ISO 12402).

- Third-Party Lab Submission: You must submit multiple finished samples of your product to an independent, accredited testing laboratory (like UL Solutions or similar certified labs).

- Rigorous Testing: The lab will subject the product to a battery of brutal tests, including:

- Buoyancy tests (does it provide the required lift?).

- Inflation tests (does it inflate reliably within a specified time?).

- Leak tests (does the bladder hold air?).

- Material strength and durability tests.

- In-water performance tests with human subjects to ensure it performs as expected.

- Approval & Production Oversight: If the product passes all tests, it receives a certification number. The factory that produces it will also be subject to periodic inspections to ensure that every unit is made to the exact same standard as the samples that were tested.

This process is non-negotiable. Designing the product is only 50% of the battle; getting it certified is the other 50%. Any manufacturing partner you choose must have experience with producing certified life-saving equipment and be willing to undergo the required factory audits.

How much does certification cost?

The cost for third-party testing and certification for a new PFD product can be substantial, often running into the tens of thousands of dollars. This is a significant investment that must be factored into the business plan from day one.

Can I sell it as a "flotation aid" without certification?

No. Making any claim about a product's ability to provide buoyancy or act as a safety device in the water without the proper certification is illegal in most countries and incredibly dangerous. It opens your company up to massive legal liability and puts your customers' lives at risk.

Conclusion

Designing a PFD-integrated cap is a serious undertaking that sits at the intersection of apparel design, mechanical engineering, and public safety. It requires a deep commitment to quality, reliability, and a safety-first mindset at every stage, from the initial concept to the final certified product. The process involves sourcing certified life-saving components, using marine-grade materials, and undergoing a rigorous and expensive third-party certification process.

This is the pinnacle of functional headwear—a product that can genuinely make a difference in a life-or-death situation. While the challenges are immense, the reward is the creation of a truly meaningful innovation in personal water safety.

At Shanghai Fumao Clothing, while our expertise is in headwear, we understand that projects like this require a new level of partnership and technical integration. We would approach such a challenge by building a coalition of experts—partnering with certified PFD component manufacturers and safety consultants to ensure the final product is not just a good hat, but a reliable piece of life-saving equipment. If you are a brand or innovator serious about tackling this challenge, we are ready to explore the possibilities with you. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com to start this critical conversation.