For retailers and brands, finding the next big thing in accessories is a constant pursuit. The foldable packable sun hat is no longer just a travel niche; it's a fashion staple with year-round demand. But how do you transition from a basic design to a product that stands out on the shelves and earns customer loyalty? The challenge lies in balancing style, durability, and packability without compromising on any front.

Designing a successful foldable packable sun hat requires a strategic focus on three core elements: selecting innovative fabrics that offer structure and memory, implementing a construction technique that defines the foldable nature, and incorporating style details that elevate it beyond a utilitarian item. It's a precise blend of material science and design aesthetics, ensuring the hat looks good both when worn and when packed away.

This guide will walk you through the critical stages of the design process. We will explore how to choose the right materials, master the construction, integrate fashion-forward elements, and ensure rigorous quality control. This will equip you with the knowledge to create a product that your customers will love.

What Materials Are Best for Foldable Sun Hats?

The journey to a perfect packable hat begins with the fabric. The wrong material can lead to a hat that crumples irreversibly, loses its shape, or feels uncomfortable. Your customers expect a hat that emerges from a bag or suitcase looking fresh and ready to wear. The key is to select fabrics with inherent resilience and memory.

The best materials combine lightweight properties with structural recovery. Fabrics like high-density paper straw, specially treated polyester-cotton blends, and innovative textiles like BAMSILK (Bamboo Silk) are excellent choices. These materials are designed to withstand repeated folding and unfolding. They bounce back to their original shape, resisting unsightly creases. Furthermore, for the modern consumer, options made from recycled materials or featuring UPF 50+ sun protection are becoming standard expectations, not just bonuses.

How to Choose Fabrics with Shape Memory?

The concept of "shape memory" is paramount. This refers to a fabric's ability to return to its original form after being deformed. When evaluating fabrics, you must look beyond just composition.

- Weave Density: A tighter weave generally offers better shape retention. For instance, a densely woven polyester blend will outperform a loose, breezy linen in terms of spring-back, though linen offers other aesthetic benefits.

- Blend Ratios: A common choice is a polyester-cotton blend. The polyester provides strength and memory, while the cotton adds softness and breathability. The exact ratio can be tuned; a higher polyester content typically enhances packability.

- Finishing Treatments: Many fabrics receive special chemical or mechanical finishes that enhance their resilience. These treatments can help the fibers resist crushing and make the fabric more amenable to folding.

| Fabric Type | Key Pros | Key Cons | Best For |

|---|---|---|---|

| High-Density Paper Straw | Excellent structure, very packable, unique aesthetic | Can be less breathable | Fashion-forward, structured styles |

| Poly-Cotton Blend | Great balance of durability, packability, and comfort | May require blends for high-end feel | All-around bestseller, high volume |

| BAMSILK (Bamboo Silk) | Naturally soft, moisture-wicking, eco-friendly appeal | Softer structure, may require careful design | Eco-conscious and comfort-focused lines |

| Tencel™ Blends | Drapes beautifully, sustainable, comfortable | Less inherent structure | Floppy, bohemian-style wide-brim hats |

What Role Do Interlinings and Wires Play?

While the outer fabric is crucial, the hidden components truly define a hat's packable character. Strategic use of interlinings and flexible wires can make the difference between a good hat and a great one.

A lightweight, fusible interlining can be added to the brim to provide a subtle body and stability without adding stiffness. This helps the hat maintain its silhouette. For wider brims, the inclusion of a flexible plastic or steel wire inside the brim edge is a game-changer. This wire allows the customer to shape the brim to their preference for optimal sun protection or style, and it can be gently bent to facilitate a clean, compact fold. The wire must be sheathed properly to prevent it from poking through the fabric, a common point of failure in low-quality hats. At our facility, we conduct durability tests on these components, simulating hundreds of folds to ensure the wire casing and stitching hold up over time.

How to Engineer the Foldable Construction?

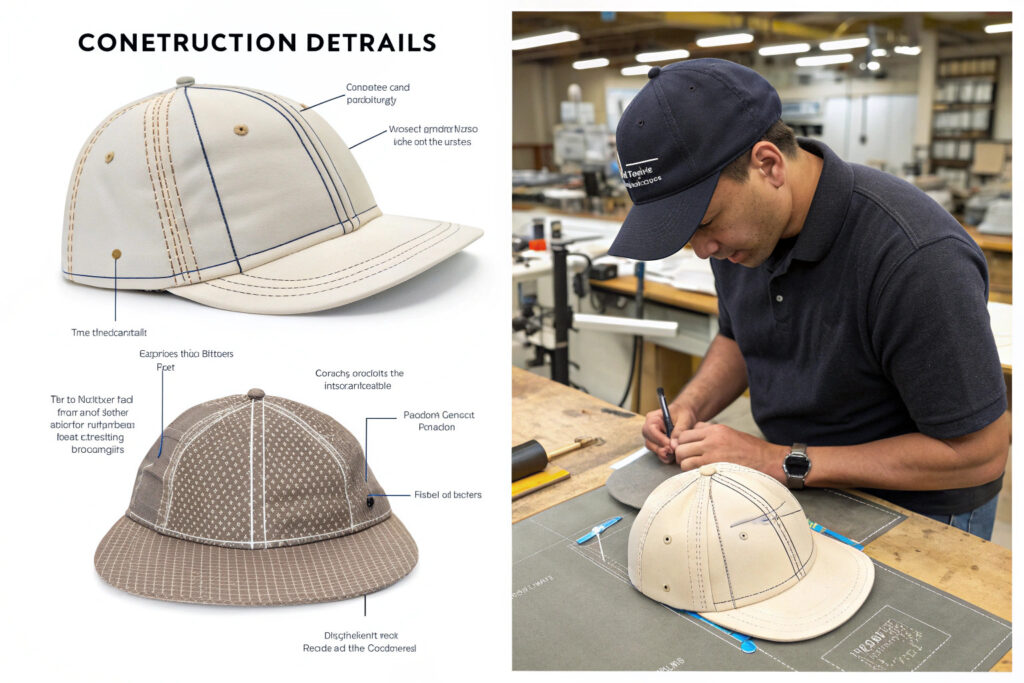

A beautiful material is useless without a construction method that leverages its packable properties. The goal is to create intentional fold lines that are part of the design, not a flaw. This requires precision patterning and stitching.

The most common and user-friendly construction is the tri-fold or quad-fold design with a central crown. This involves creating designated folding points along the brim, often reinforced with a specific stitch pattern. The crown itself is a critical component; a soft, unstructured crown made from the same flexible material as the brim is ideal. Alternatively, a collapsible crown with soft pleats or gussets allows it to flatten completely. The key is to avoid rigid internal headbands or bulky seams that create bulk and prevent a flat fold.

What Are the Key Stitching Techniques for Durability?

Stitching is the backbone of your hat's lifespan. For high-stress areas like the fold lines and the joint where the crown meets the brim, standard straight stitching may not be sufficient.

We recommend employing bar tack stitching at these critical stress points. A bar tack is a dense, concentrated zigzag stitch that distributes tension over a wider area, dramatically reducing the chance of seam failure. Additionally, using high-tenacity polyester thread ensures the stitches themselves can withstand the repeated stress of folding and unfolding without breaking. This attention to detail in the garment construction phase is what separates a product that lasts for seasons from one that fails after a few trips.

How to Design a Compact and Protective Packing Solution?

The "packable" experience is incomplete without a thoughtful packing solution. Simply stuffing the hat into a bag is not what your customers have in mind.

Including a lightweight, breathable storage pouch is essential. This pouch protects the hat from dust and snags when in a suitcase. For premium products, consider a rigid, circular box that holds the hat in a pre-folded state, completely eliminating the guesswork for the consumer. The material of the pouch should be breathable, like non-woven polyester or cotton, to prevent moisture buildup and mildew. This final touch demonstrates a brand's commitment to quality and enhances the unboxing experience, making the product feel more valuable.

How to Integrate Style with Packability?

The biggest misconception is that packable hats must be plain or utilitarian. Today's market demands fashion-forward designs. The trick is to integrate style elements that are compatible with the hat's foldable function.

Color and trim are your best tools. Offering a range of colors, from classic neutrals to seasonal brights, allows the hat to be a style statement. Decorative elements like a contrasting grosgrain ribbon band, a subtle leather logo patch, or a removable fabric flower can add significant perceived value. However, these elements must be chosen and attached with packability in mind. A large, rigid ornament will hinder folding, so opt for flat, flexible trims that can withstand being packed down.

What Brim Styles Are Most Compatible with Folding?

The brim style is the most visible design element and directly impacts packability.

A medium to wide brim with a uniform, all-around shape is the most versatile for folding. It provides ample sun protection and can be engineered with a flexible wire for easy tri-folding. Floppy brims are also excellent as they have no rigid structure to begin with. Styles that are more challenging include upswept brims or stiff, asymmetrical designs, as their specific shapes are more difficult to flatten without complex folding patterns. For most brands entering this category, starting with a classic round-brimmed style is the most reliable path to success.

How to Select Colors and Trims for Market Appeal?

Your color and trim selections should be data-driven, not just based on gut feeling. We use AI-driven trend analysis to forecast color palettes and decorative details that are gaining traction in key markets like the EU and North America.

For instance, earthy tones and classic neutrals often form a strong baseline collection, while a capsule of vibrant prints or pastels can attract attention for seasonal promotions. When it comes to trims, a branded ribbon is a must for brand recognition. For a feminine touch, a fabric bow or a braided cord can be highly effective. The key is to prototype these designs and physically test their packability to ensure the style elements do not compromise the core function.

How to Ensure Quality in Mass Production?

A perfect prototype means nothing if it cannot be replicated consistently in a production run of 10,000 units. Quality control for packable hats must be proactive and integrated throughout the manufacturing process.

This starts with incoming material inspection. Every batch of fabric and component is tested in our CNAS-accredited lab for properties like colorfastness, shrinkage, and seam slippage. During production, we implement a combination of inline and final inspections. Inline inspectors monitor critical operations like wire insertion and bar tack stitching, catching defects in real-time. Final inspection involves a statistical sampling of finished hats, where they are physically folded and unfolded multiple times to simulate real-world use and check for any shape recovery failure or construction issues.

What Tests Guarantee Long-Term Shape Recovery?

The most important test for a packable hat is the Cycle Compression Test. In this test, a hat is mechanically folded and compressed in a controlled manner for a set number of cycles (e.g., 100 cycles). After the test, it is left to rest and then evaluated against a standard for how well it returns to its original shape. Any significant permanent deformation or creasing means the material or construction is not adequate. This test, along with tests for colorfastness to perspiration and light, ensures the product you receive is durable and reliable.

How to Implement Effective Quality Control Checks?

A successful QC system is built on clear, measurable standards and checkpoints. We use a detailed Quality Control Checklist for every order, which includes:

- Pre-Production Meeting: Aligning on all specs, including fold points and packing method.

- During Production (DUPRO) Checks: Random checks on the assembly line for stitching consistency, wire placement, and trim attachment.

- Final Random Inspection (FRI): Following international statistical sampling standards (like AQL), inspectors check for workmanship, size, shape, function, and packaging. Each hat is folded and unfolded to ensure the core feature works perfectly.

This multi-stage process, supported by digital QC platforms that provide real-time data, guarantees a consistent and high-quality product, minimizing the risk of returns and protecting your brand's reputation.

Conclusion

Designing a best-selling foldable packable sun hat is a detailed process that merges smart material selection with intentional construction and stylish design. It's about creating a product that is as functional as it is fashionable, one that delivers on its promise of convenience without sacrifice. By focusing on shape-memory fabrics, reinforced construction, and market-relevant aesthetics, you can develop a product line that captures significant market share and builds brand loyalty.

If you are looking for a manufacturing partner to bring your foldable hat designs to life with precision, quality, and speed, we are here to help. Our team specializes in turning concepts into high-yielding commercial products. For a direct conversation about your specific needs, please contact our Business Director Elaine at elaine@fumaoclothing.com. Let's create something remarkable together.