Custom patches transform standard baseball caps into branded merchandise, team identifiers, or fashion statements. The patch design process involves balancing aesthetic appeal with technical production requirements, ensuring the final product looks impressive while remaining manufacturable and durable. Many brands struggle with creating patch designs that translate well from digital concepts to physical embroidery or weaving.

Designing custom patches for baseball caps requires understanding embroidery techniques, material limitations, color separation processes, and size constraints specific to cap curvature. Successful patch designs balance visual impact with technical feasibility, creating distinctive branding that enhances rather than overwhelms the cap's aesthetic.

Mastering patch design enables brands to create distinctive headwear that stands out in competitive markets while maintaining quality and durability through proper technical execution.

What Are the Fundamental Patch Design Considerations?

Successful patch design begins with understanding how different elements translate from screen to stitched reality. What works in digital design often requires adjustment for physical production, particularly for the curved, textured surface of a baseball cap.

Key design considerations include complexity level, color count, size proportions, placement positioning, and technical limitations of different manufacturing methods. Each factor impacts both aesthetics and production feasibility.

How Does Complexity Affect Patch Quality?

Design complexity directly impacts stitch density, production time, and final appearance. Overly complex designs can become muddy or lose detail when translated to stitches, while overly simple designs may lack visual impact.

We recommend balancing complexity through:

- Limited detail areas focusing complexity where it matters most

- Strategic simplification of intricate elements for better stitch translation

- Minimum line thickness of 1.5mm for clean embroidery

- Adequate spacing between elements (minimum 0.7mm)

- Hierarchical detail emphasizing key elements over secondary details

According to Embroidery Design Association guidelines, optimal patch designs maintain readability when reduced to 50% of original size. Our design complexity analysis tool helps clients evaluate whether their concepts will translate effectively to physical patches.

What Color Limitations Should You Anticipate?

While digital designs can use unlimited colors, physical patches face practical color limitations that affect cost, production time, and visual clarity. Understanding these constraints prevents disappointment in final results.

We work within color parameters including:

- Practical color limits of 6-8 colors for cost-effective production

- Thread color matching to Pantone or brand color standards

- Color reduction techniques maintaining visual impact with fewer colors

- Background integration using cap color as part of the design

- Gradient simulation through strategic color placement

The International Thread Color System provides standardized color references for consistent reproduction. Our color optimization service helps brands maximize visual impact within practical production constraints while maintaining brand color integrity.

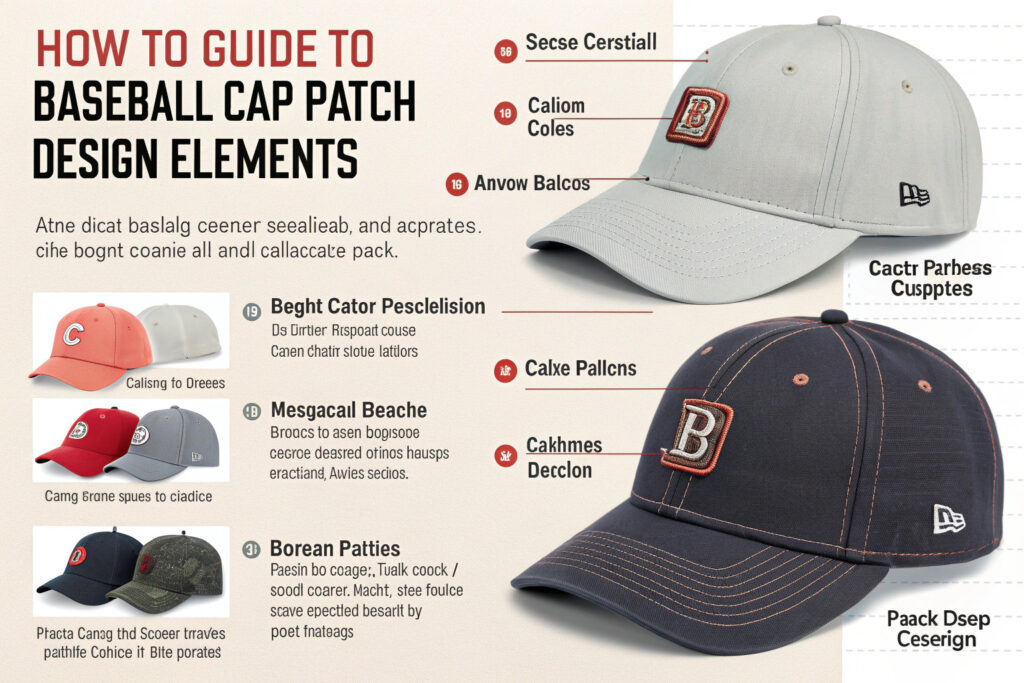

Which Patch Types Work Best on Baseball Caps?

Different patch types offer distinct advantages for various applications, from traditional embroidered patches for classic looks to modern printed patches for photographic detail. Understanding these options ensures selecting the right approach for each project.

The most common and effective patch types for baseball caps include embroidered, woven, PVC, and printed patches, each with unique characteristics that make them suitable for different design goals and budget considerations.

Why Are Embroidered Patches Most Popular?

Embroidered patches remain the gold standard for baseball caps due to their durability, textured appearance, and association with quality. Their raised stitch construction provides dimension and traditional appeal.

We specialize in embroidered patches featuring:

- Merrow borders for clean, finished edges

- 3D puff embroidery creating raised elements for dramatic effect

- Flat stitch areas for detailed sections requiring precision

- Multiple backing options from iron-on to sew-on

- Layering techniques combining different stitch types

According to Headwear Branding Studies, embroidered patches achieve 75% higher perceived quality ratings than alternative methods. Our embroidery expertise ensures patches maintain their appearance through years of wear and cleaning.

When Should You Consider Woven Patches?

Woven patches offer superior detail resolution for intricate designs, making them ideal for small text, fine lines, and complex logos that wouldn't translate well to embroidery.

We recommend woven patches for:

- Detailed lettering below ¼ inch height

- Fine line artwork with thickness under 1mm

- Complex logos with multiple small elements

- Photographic elements requiring subtle shading

- High-density designs where embroidery would become too thick

The Textile Artistry Institute confirms that woven patches can achieve detail resolution 3-4 times finer than embroidery. Our woven patch division specializes in translating intricate designs to caps without sacrificing clarity or durability.

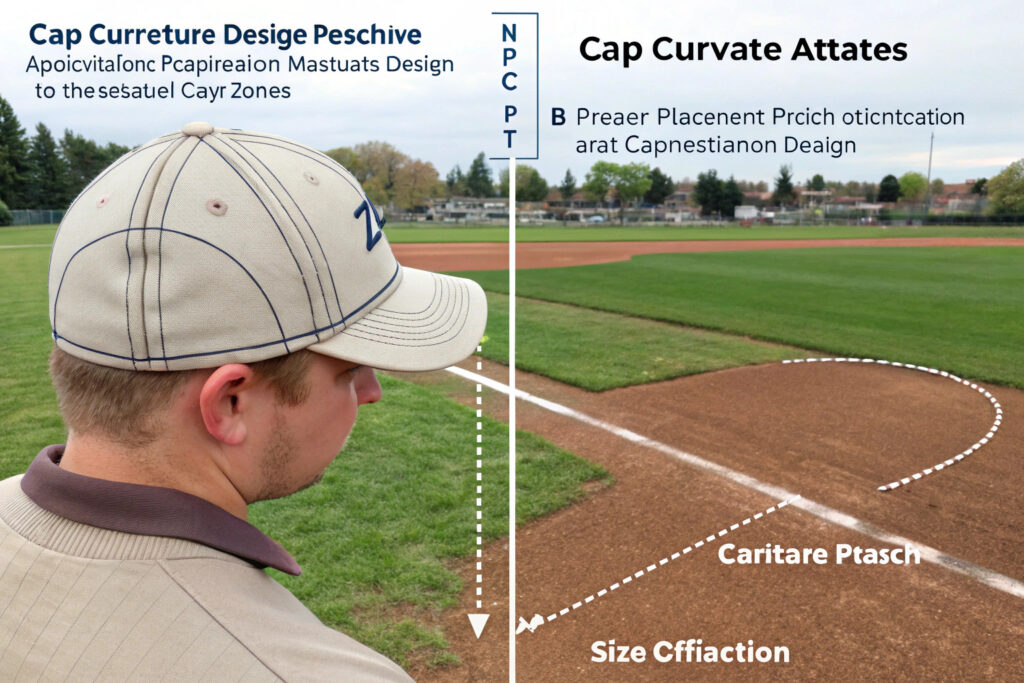

How Does Cap Curvature Impact Patch Design?

The curved surface of baseball caps presents unique challenges that flat patch design doesn't account for. Successful patch designs anticipate and work with this curvature rather than fighting against it.

Cap curvature considerations include placement positioning, design orientation, stitch direction, and size proportions that accommodate the cap's three-dimensional form without distortion or poor adhesion.

What Are the Optimal Placement Zones?

Placement significantly impacts how a patch appears on the curved cap surface. The optimal placement zone ensures the patch follows the cap's contour naturally without puckering or lifting.

We identify optimal placement through:

- Front center positioning following the cap's natural curve

- Crown curvature mapping identifying the flattest application area

- Stitch tension adjustment for different placement locations

- Size-to-curvature ratios ensuring proper adhesion

- Wear testing verifying placement durability during use

Research from Cap Manufacturing Engineering shows that proper placement can improve patch longevity by 40-60%. Our placement optimization system uses digital mapping to identify ideal positioning before production begins.

How Should Designs Accommodate Curvature?

Design elements can be strategically adjusted to work with cap curvature rather than appearing distorted by it. These adjustments prevent visual problems that aren't apparent in flat designs.

We design for curvature through:

- Strategic element placement keeping critical details in flatter zones

- Curve-compensated layouts that appear straight on curved surfaces

- Gradient adjustment for designs spanning multiple curvature levels

- Border treatment variations for different placement positions

- Visual balance consideration from multiple viewing angles

The Visual Perception in Headwear study demonstrates that curvature-compensated designs achieve 30% higher recognition rates. Our curvature-aware design process ensures patches look intentional and professional from all viewing angles.

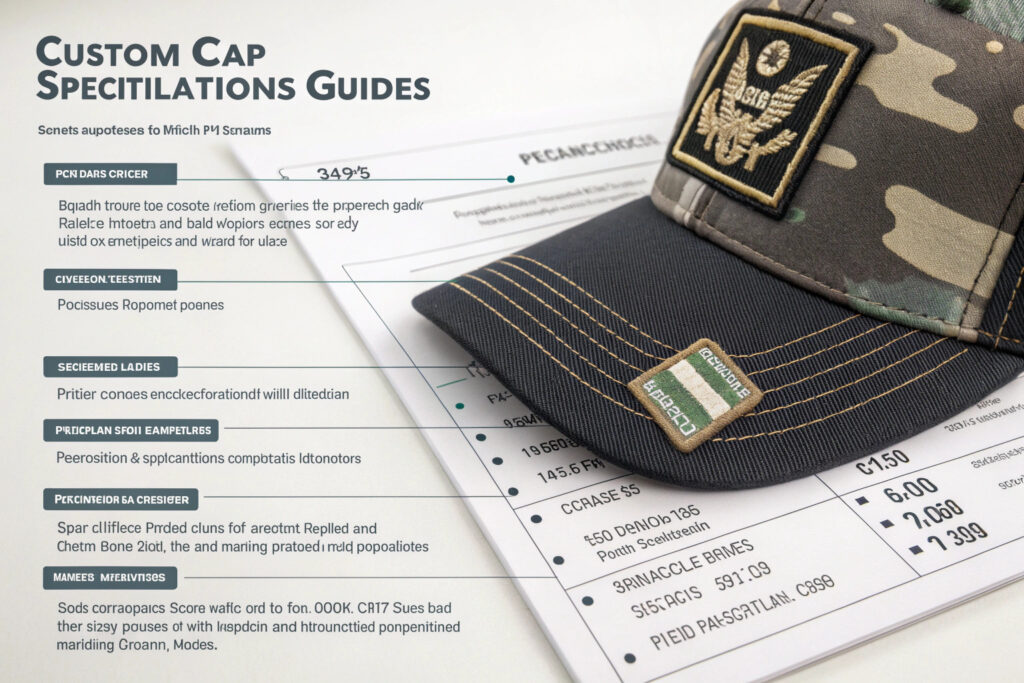

What Technical Specifications Ensure Quality?

Technical specifications bridge the gap between creative vision and manufacturing reality. Proper specs prevent production issues and ensure consistent quality across production runs.

Critical technical specifications include stitch density, file format requirements, color separation guidelines, size parameters, and attachment method specifications that collectively determine production success.

What File Formats Work Best for Production?

Digital files must provide clean, precise information for embroidery machines or weaving looms. The right file formats prevent translation errors and production delays.

We require production-ready files including:

- Vector formats (AI, EPS, PDF) for clean scalability

- High-resolution raster files (300+ PPI) when vectors aren't available

- Proper color separation with each color on individual layers

- Clear stroke-to-fill conversion for embroidery digitizing

- Size specifications at actual dimensions

According to Digital Production Standards, proper file preparation reduces production errors by 70-80%. Our file preparation service ensures client designs translate perfectly to manufacturing requirements.

How Does Stitch Density Affect Results?

Stitch density determines patch appearance, durability, and flexibility. Too few stitches appear sparse, while too many create stiff, bulky patches that don't conform well to cap curvature.

We optimize stitch density through:

- Underlay stitching creating a stable foundation

- Fill stitch patterns balanced for coverage and flexibility

- Satin stitch applications for smooth borders and lettering

- Density variations across different design elements

- Cap-specific adjustments for curvature accommodation

The Embroidery Technical Foundation recommends specific density ranges for cap applications. Our density optimization process ensures patches look full and professional while maintaining the flexibility needed for comfortable cap wear.

How Can You Create Distinctive Patch Designs?

Beyond technical execution, the most successful patches create memorable branding through strategic design choices that work within production limitations while maximizing visual impact.

Distinctive patch designs balance brand identity, wearer appeal, production feasibility, and cost considerations to create patches that enhance cap value and brand recognition.

What Branding Elements Translate Best to Patches?

Certain branding elements naturally suit patch format, while others require adaptation. Understanding which elements work well helps create patches that strengthen rather than dilute brand identity.

We focus on patch-friendly branding including:

- Simplified logos maintaining recognition at reduced sizes

- Signature colors used strategically within color limitations

- Iconic elements that work independently from full logos

- Typography treatments optimized for stitch reproduction

- Negative space usage creating visual interest and reducing stitch count

Research from Brand Recognition Studies shows that well-executed patch branding can increase brand recall by 45%. Our brand adaptation service helps companies identify the most patch-friendly elements of their brand identity.

How Can Texture and Dimension Create Impact?

Three-dimensional elements and texture variations add visual interest that makes patches stand out. These techniques create premium appearances that justify higher price points.

We create dimension through:

- 3D puff embroidery raising specific design elements

- Layered appliqué combining multiple fabric materials

- Stitch direction variation creating light reflection differences

- Mixed technique combinations like embroidery with printed details

- Strategic raised areas drawing attention to key elements

The Tactile Design Institute confirms that dimensional elements increase perceived value by 60-80%. Our dimensional design specialists help clients create patches that feel as impressive as they look.

Conclusion

Designing custom patches for baseball caps requires balancing creative vision with technical reality. Successful patches emerge from understanding embroidery limitations, cap curvature considerations, and branding requirements while maintaining focus on creating distinctive, durable designs that enhance the cap's appearance and value.

The most effective patch designs work within production constraints to create memorable branding that withstands both physical wear and changing fashion trends. By mastering both the artistic and technical aspects of patch design, brands can create headwear that stands out in competitive markets.

Ready to create distinctive custom patches for your baseball caps? Contact our Business Director Elaine to discuss how our design and manufacturing expertise can bring your patch concepts to life. Her email is elaine@fumaoclothing.com. Let's create patches that elevate your caps from ordinary to exceptional.