You've decided to create your own line of custom baseball caps and you're looking to manufacture them in bulk. You've probably heard that China is the place to do it, but the process seems daunting. How do you find a reliable factory? How do you communicate your design? What about quality, shipping, and all the hidden costs? It feels like a huge risk, and you're worried about making a costly mistake.

As someone who has been on the other side of this process for over 20 years, I can tell you that bulk ordering custom baseball caps from China is a straightforward and highly efficient process if you follow a clear roadmap. The key is to define your product specifications clearly, find a reliable manufacturing partner, approve a pre-production sample, and understand the logistics of payment and shipping. It's a partnership built on clear communication and trust.

My company, Shanghai Fumao Clothing, is rooted in the heart of China's hat industry. We've helped hundreds of entrepreneurs, buyers, and global brands just like you navigate this journey successfully. Let me walk you through the exact steps we use with our clients, demystifying the process and giving you the confidence to place your first bulk order.

How Do You Finalize Your Cap Design & Tech Pack?

Before you can get a price, you need to know exactly what you want to make. Simply saying "I want a black baseball cap with my logo" isn't enough. The first and most crucial step is to create a detailed "tech pack." This is the blueprint for your hat, and it's the most important document you will create.

A good tech pack for a baseball cap should include:

- Hat Style: Is it a 6-panel, 5-panel, or unstructured "dad hat"?

- Fabric: What material do you want? Cotton twill, polyester, corduroy, wool? Specify the weight (e.g., 108x56 cotton twill).

- Color: Provide specific Pantone (PMS) color codes for the crown, brim, eyelets, and stitching.

- Logo/Artwork: Include high-resolution vector files (like .AI or .EPS) of your logo. Specify the application method: 3D embroidery, flat embroidery, woven patch, screen print?

- Construction Details: Specify the type of closure (snapback, leather strap, metal buckle), eyelet style (sewn or metal), and any interior details like custom taping or labels.

- Measurements: Include key measurements like crown height and brim length.

Creating a detailed tech pack minimizes misunderstandings. It allows a manufacturer like us to give you an accurate price and a realistic production timeline. It's the foundation of a smooth process. The more detail you provide upfront, the fewer surprises you'll have later. This detailed planning is the first part of finding the right manufacturing partner.

What if I don't know how to create a tech pack?

Don't worry, this is very common. An experienced manufacturer can help you. At our company, we often work with clients to build their tech packs from scratch. You can provide sketches, photos of hats you like, and your logo, and our development team can translate your vision into a professional technical document for your approval. It's a collaborative process.

Why are Pantone colors so important?

Computer screens display colors differently. The "red" on your screen could look completely different from the "red" on my screen. Pantone is a standardized color matching system that ensures we are all talking about the exact same shade. Using Pantone codes is the only way to guarantee color accuracy in the final product, a standard practice recommended by design resources like 99designs.

How Do You Find the Right Manufacturer?

Once your tech pack is ready, it's time to find a factory. This is where many people get overwhelmed. You can use platforms like Alibaba, attend trade shows, or use Google to find potential suppliers. But how do you know who to trust?

You need to vet your potential partners carefully. Don't just look for the lowest price. Look for:

- Specialization: Do they specialize in hats? A factory that makes t-shirts and "also" makes hats will not have the same level of expertise or specialized machinery.

- Communication: Are they responsive, professional, and fluent in your language? Clear communication is essential to avoid costly errors.

- Certifications: Do they have certifications like ISO 9001 (for quality management) or BSCI (for social compliance)? This shows a commitment to professional standards.

- Transparency: Are they willing to show you photos of their factory, explain their process, and provide references? A good partner has nothing to hide.

At Shanghai Fumao Clothing, we pride ourselves on being a partner, not just a supplier. We provide our clients with a dedicated account manager, share videos of our production process, and guide them through every decision. Finding a manufacturer is like hiring an employee; you need to find one with the right skills, experience, and attitude. Once you've found a few potential partners, the next step is to get a quote and move to the sampling stage.

Is Alibaba a good place to find suppliers?

Alibaba can be a great starting point, but you must do your due diligence. Look for "Gold Suppliers" with many years of experience and a high transaction level. Read reviews carefully. Always treat the initial contact as the beginning of a vetting process. Platforms like Jungle Scout offer excellent guides on how to safely navigate the platform and verify suppliers.

What is a reasonable MOQ for custom caps?

MOQ stands for Minimum Order Quantity. For custom baseball caps from a decent-sized factory, the MOQ is typically between 100 and 300 pieces per design/color. This is because setting up the machinery, cutting the fabric for a specific design, and programming the embroidery machines has a fixed cost. Spreading that cost over a larger number of units makes the per-piece price affordable.

Why Is the Pre-Production Sample So Important?

Never, ever skip the sample stage. I cannot stress this enough. A pre-production sample (PPS) is a physical, finished version of your hat made for your approval before the factory starts the bulk order. This is your last chance to catch any mistakes and make final changes.

When you receive your sample, you must check it against your tech pack with extreme care:

- Check the Colors: Do the fabric and embroidery colors match your Pantone codes?

- Check the Quality: Is the stitching straight and clean? Is the embroidery sharp? Does the hat feel solid?

- Check the Fit and Shape: Put the hat on. Is the crown height correct? Does it fit comfortably? Is the brim curved correctly?

- Check the Details: Is your custom label stitched in correctly? Is the closure the right type and quality?

If there are any issues, now is the time to address them. Provide clear feedback and photos to your manufacturer. They may need to make a revised sample. Only after you have given your 100% written approval of the PPS should you authorize the factory to begin bulk production. This sample is the "master copy" that the entire bulk order will be judged against. It is your single most important quality control tool and the final step before you discuss payment and shipping.

How much does a sample cost?

A sample typically costs between $50 and $150. This fee covers the labor for a single piece and the cost of materials. Many manufacturers, including us, will refund the sample fee or deduct it from the total cost of the bulk order once you place it. The cost is a small price to pay for the insurance it provides.

How long does it take to get a sample?

From finalizing the tech pack, it usually takes 1 to 2 weeks to produce the sample. International shipping via a courier like DHL or FedEx will then take another 3-7 days. You should budget about 3 weeks for the entire sampling process.

How Do Payment and Shipping Work?

Once you approve the sample, it's time to talk money and logistics. The payment and shipping process is fairly standardized in the manufacturing industry.

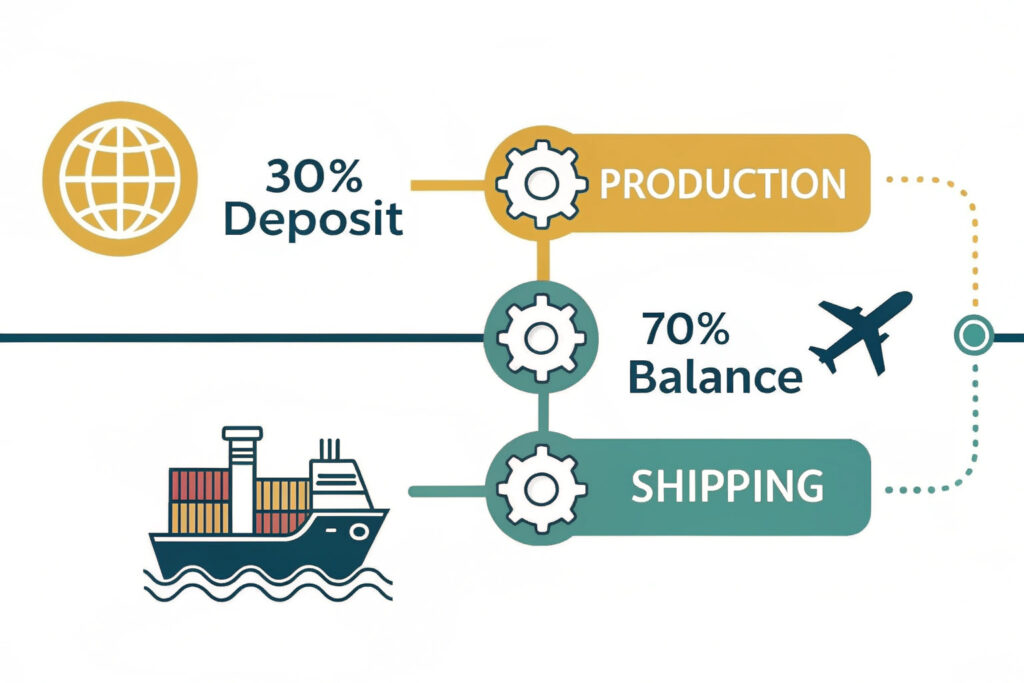

Payment Terms:

The most common payment structure is a 30% deposit to start the bulk production and a 70% balance payment due upon completion, before the goods are shipped. The initial deposit is used by the factory to purchase the raw materials for your order. No reputable factory will start production without a deposit. Payments are typically made via international wire transfer (T/T).

Shipping (Incoterms):

You need to agree on the shipping terms, known as Incoterms. The most common are:

- EXW (Ex Works): You are responsible for picking up the goods from the factory. You handle all shipping, export, and import procedures. This gives you the most control but is also the most work.

- FOB (Free On Board): This is the most popular option. The manufacturer is responsible for getting the goods to the designated port in China (e.g., FOB Shanghai). From that point on, you are responsible for the sea/air freight, insurance, and import process in your country.

- DDP (Delivered Duty Paid): The manufacturer handles everything—shipping, insurance, customs clearance, and duties. The goods arrive at your door. This is the easiest option but also the most expensive, as the manufacturer charges a premium for this full service.

For most new importers, FOB is the best balance of cost and control. You can hire a freight forwarder in your own country to manage the shipping from the Chinese port to your warehouse. A good freight forwarder is a valuable partner who can handle all the complex paperwork of international logistics.

What is a freight forwarder?

A freight forwarder is a company that organizes shipments for individuals or corporations to get goods from the manufacturer to a final destination. They don't move the goods themselves but act as an intermediary between you and the various transportation services. Companies like Flexport have built entire platforms to simplify this process for importers.

How long does bulk production and shipping take?

After sample approval, bulk production for a few hundred to a few thousand caps typically takes 25-40 days. Sea freight from China to the US or Europe can take another 30-45 days. Air freight is much faster (5-10 days) but significantly more expensive. All in, you should plan for about 2-3 months from the day you approve your sample to the day the goods arrive at your warehouse.

Conclusion

Bulk ordering custom baseball caps from China doesn't have to be a complicated or risky endeavor. By following a structured process—creating a detailed tech pack, carefully vetting your manufacturing partner, insisting on a perfect pre-production sample, and understanding the terms of payment and shipping—you can turn your vision into a high-quality product, ready for your market. The key is to be diligent, communicate clearly, and view your manufacturer as a partner in your success.

We've built our business on this principle of partnership. For over two decades, we've helped brands launch and scale by providing them with a transparent, reliable, and high-quality manufacturing solution.

If you're ready to take the next step and create your own line of custom hats, my team at Shanghai Fumao Clothing is here to guide you through every stage of the process. Let's build something great together. Please feel free to reach out to our Business Director, Elaine, at her email: elaine@fumaoclothing.com to get your project started.