Wearing the wrong hat in humid weather can feel like a sauna on your head. The discomfort of sweat-soaked fabric and the worry about odor buildup can ruin any outdoor experience. Many people abandon hats altogether in humid climates, missing out on essential sun protection.

The best hat materials for humid climates are natural fibers like breathable cotton and moisture-wicking bamboo, along with technical performance fabrics including quick-dry polyester and ventilated mesh. These materials manage sweat effectively while maintaining comfort and durability in high-humidity conditions.

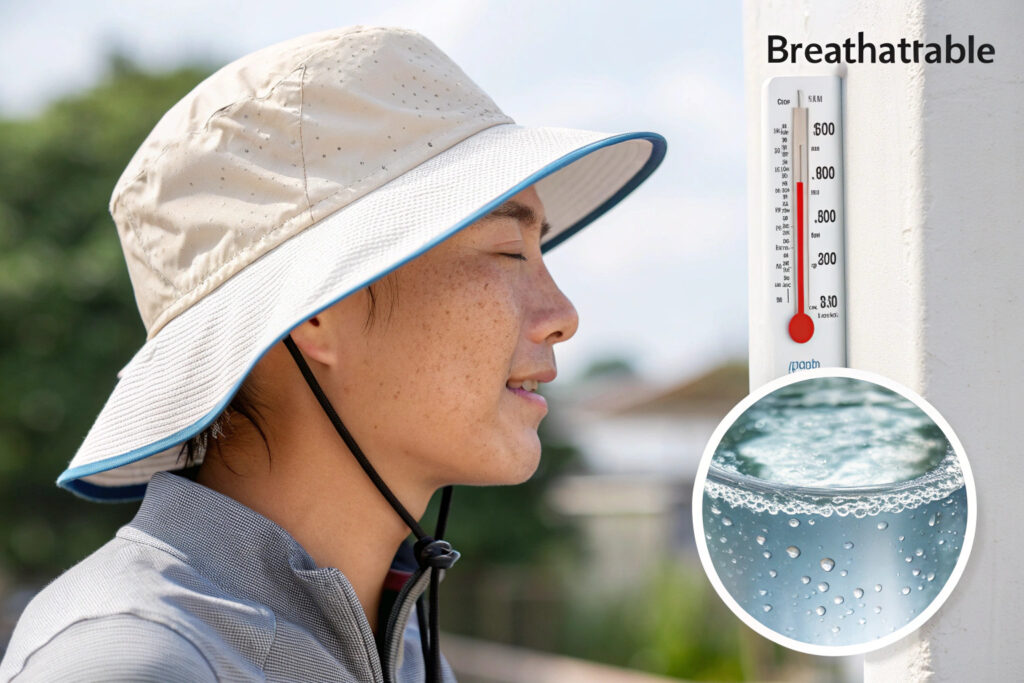

Why Does Breathability Matter in Humid Weather?

Breathability isn't just a marketing term - it's the scientific principle that determines how well air circulates through fabric. In humid conditions, this airflow becomes crucial for temperature regulation and moisture management.

Breathability matters because it allows heat and moisture vapor to escape from your skin, preventing that sticky, suffocating feeling. Materials with good breathability create a cooling microclimate around your head while wicking sweat away from your skin.

How Do Natural Fibers Enhance Air Circulation?

Natural fibers like cotton and bamboo contain microscopic pores that facilitate air movement. Cotton's natural fiber structure allows it to absorb significant moisture - up to 27% of its weight - while still feeling dry to the touch. This absorption capability pulls sweat away from your skin, where it can evaporate more efficiently. The moisture-wicking properties of bamboo are even more impressive, as the fiber's cross-section contains micro-gaps that enhance ventilation and speed up evaporation.

What Makes Mesh and Ventilated Designs Effective?

Strategic design elements can dramatically improve a hat's performance in humidity. Mesh panels, particularly in the crown area, create dedicated airflow channels that let heat escape rapidly. Ventilation eyelets, grommets, and strategic seam placements work together to create a chimney effect, drawing cool air in and pushing warm air out. These design features transform even less-breathable materials into effective humidity-fighting headwear through intelligent engineering.

Which Natural Fibers Work Best in Humidity?

Natural fibers have evolved over millennia to handle environmental challenges, making them particularly well-suited for humid conditions. Their biological structures offer inherent advantages that synthetic materials often try to mimic.

The best natural fibers for humid climates include lightweight cotton for its absorbency, bamboo for its antibacterial properties and superior wicking, and straw for its open-weave ventilation. These materials work with your body's natural cooling systems rather than fighting against them.

Why is Cotton Still a Popular Choice?

Cotton remains a go-to for humid weather because of its proven performance and comfort. The fiber's hollow core acts like tiny straws, pulling moisture along its length to spread it across a larger surface area for faster evaporation. However, not all cotton is equal - organic cotton with a looser weave provides better airflow than dense, heavily processed varieties. While pure cotton can become heavy when completely saturated, cotton-polyester blends offer improved drying times while maintaining good moisture absorption.

What Gives Bamboo Its Superior Performance?

Bamboo fiber represents a significant advancement in natural material technology. The manufacturing process creates micro-holes throughout the fiber that enhance breathability beyond what natural cotton can achieve. More importantly, bamboo contains a natural bio-agent called "bamboo kun" that resists bacterial growth, preventing the odor development that plagues other moist fabrics. This combination of physical structure and natural antibacterial properties makes bamboo ideal for extended wear in humid conditions.

How Do Technical Fabrics Manage Moisture?

Technical fabrics take a scientific approach to humidity management, using engineered fibers and specialized constructions to outperform natural materials in specific ways. These innovations have revolutionized performance headwear.

Technical fabrics manage moisture through hydrophobic treatments that repel liquid sweat, capillary action that pulls moisture to the fabric's exterior, and rapid evaporation technologies that use surface area maximization to speed up drying times significantly.

What is the Science Behind Moisture-Wicking?

Moisture-wicking isn't magic - it's physics. Technical polyester fibers are engineered with microscopic channels that use capillary action to pull sweat away from your skin. This directional movement relies on the principle that liquid naturally flows toward drier areas. The moisture management capabilities of these fabrics are measured using standardized tests like the AATCC Moisture Management Tester, which evaluates absorption rate, spreading speed, and evaporation rate across the fabric surface.

How Do Quick-Dry Technologies Work?

Quick-dry technologies combine fiber engineering with fabric construction to minimize drying time. These fabrics achieve rapid drying through three key methods:

- Hydrophobic fiber surfaces that don't absorb water internally

- Yarn construction that creates spaces for air circulation

- Thin fabric weights that minimize water retention

The result is fabric that can go from soaked to wearable in under 30 minutes under optimal conditions, making it perfect for tropical climates or high-activity use where frequent sweating occurs.

What Material Combinations Work Best?

Sometimes, the optimal solution comes from combining materials to leverage their individual strengths while minimizing their weaknesses. Strategic material combinations can create headwear that outperforms any single fabric.

The best material combinations for humid climates include cotton-polyester blends that balance absorption and drying, bamboo-Tencel™ mixes that enhance natural cooling, and hybrid designs that place technical fabrics in sweat zones while using natural fibers elsewhere for comfort.

Why Do Blended Fabrics Often Outperform Pure Materials?

Blended fabrics create synergistic effects that pure materials can't achieve alone. A typical 65% polyester/35% cotton blend offers the quick-drying properties of synthetic fiber while maintaining the comfort and absorbency of natural cotton. The fabric blend technology allows manufacturers to fine-tune performance characteristics like stretch recovery, durability, and moisture management. These engineered solutions demonstrate how material science has evolved to address specific environmental challenges.

How Can Strategic Panel Placement Enhance Performance?

Advanced hat designs use different materials in specific zones to optimize overall performance. Common strategic placements include:

- Moisture-wicking headbands in direct contact with the forehead

- Mesh crown panels for maximum ventilation

- Durable brim materials that maintain shape and sun protection

- Quick-dry sweatbands that target the highest-perspiration areas

This zoning approach acknowledges that different parts of your head have different needs in humid conditions, allowing for targeted material selection that addresses each requirement specifically.

Conclusion

Choosing the right hat material for humid climates involves understanding how different fibers manage moisture, promote airflow, and resist odor. The optimal choice balances breathability, quick-drying capability, and comfort to keep you protected and comfortable regardless of humidity levels.

If you're developing headwear for humid markets, our material experts can help select the perfect fabrics for your specific needs. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss humidity-resistant hat materials and manufacturing solutions.