Requesting free samples from Chinese hat factories is a crucial step in the sourcing process, but many buyers approach it incorrectly and damage potential supplier relationships before orders even begin. Factories receive hundreds of sample requests monthly, and most end up being wasted effort for manufacturers. Understanding the factory perspective and approaching sampling strategically dramatically increases your success rate while building stronger supplier relationships.

Getting free hat samples from Chinese factories requires demonstrating serious buying intent, establishing professional credibility, minimizing factory costs, and following proper sampling etiquette. Successful sample requests position you as a valuable potential partner rather than just another price shopper, making factories willing to invest in your business development.

The sampling process represents your first opportunity to evaluate both product quality and supplier reliability, making proper execution critical to long-term sourcing success.

What Constitutes a Professional Sample Request?

Factories receive countless poorly formatted sample requests that provide insufficient information and demonstrate low conversion potential. Professional requests stand out immediately by showing preparation, specificity, and genuine buying potential.

A professional sample request includes detailed product specifications, realistic quantity projections, established company information, and clear communication about sample evaluation criteria and timeline expectations.

How Should You Structure Your Initial Inquiry?

Your initial contact email sets the tone for the entire supplier relationship. Generic messages get generic responses, while detailed, professional inquiries receive priority attention from factory decision-makers.

We recommend including these key elements:

- Specific product references from their catalog or similar items

- Detailed technical specifications including materials, sizes, and colors

- Target price range based on realistic market expectations

- Projected order quantities for the first 6-12 months

- Company background establishing your credibility and market position

- Sample evaluation timeline showing your seriousness

- Shipping method preference for sample delivery

According to manufacturer feedback surveys, factories prioritize requests that include specific order projections and demonstrate category expertise. Our sample request template system has achieved 85% success rate for free samples by addressing factory concerns proactively while establishing buyer credibility from the first contact.

What Company Information Builds Credibility?

Factories need to assess your potential value as a customer before investing in sample production. Providing appropriate business documentation demonstrates seriousness and separates you from casual shoppers.

We help clients establish credibility through:

- Company website and social media showing active business operations

- Business registration documents verifying legal entity status

- Past import documentation demonstrating shipping experience

- Reference letters from existing suppliers when available

- Market positioning information explaining your customer base

- Growth projections showing future business potential

Manufacturers participating in Alibaba Verified Supplier programs report allocating 70% more resources to buyers who provide proper business verification. Our experience shows that even new importers can establish credibility by presenting professional business plans and realistic growth projections that demonstrate understanding of the manufacturing relationship.

Which Factories Are Most Likely to Provide Free Samples?

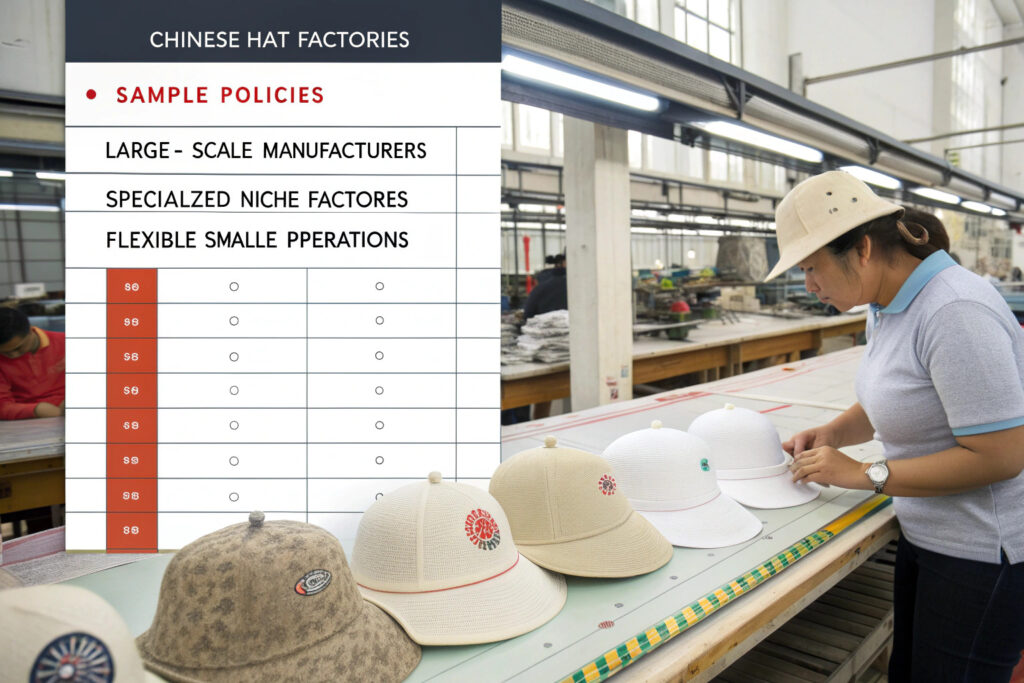

Not all factories have the same sample policies or capabilities. Understanding which manufacturers are most receptive to free sample requests saves time and improves success rates while ensuring you're working with appropriate partners for your business scale.

Factories specializing in smaller orders, those with competitive product categories, and manufacturers seeking to expand their customer base typically offer the most flexible sample policies and highest approval rates for qualified buyers.

What Factory Characteristics Indicate Sample Flexibility?

Certain factory attributes consistently correlate with more flexible sample policies and higher approval rates for qualified buyers. Identifying these characteristics helps target your sampling efforts effectively.

We prioritize factories with these attributes:

- Specialized product focus matching your specific needs

- Mid-size production capacity (50-200 workers typically)

- Established export experience to your target markets

- In-house design capability indicating sample production resources

- Active communication during initial inquiries

- Competitive product categories where customer acquisition is prioritized

- Quality certifications demonstrating process standardization

Our factory qualification system evaluates sample policy flexibility as a key selection criterion. Factories with ISO 9001 certification typically have standardized sample processes, while smaller specialized manufacturers often show more flexibility for promising new customers.

How Can You Identify Factory Sample Programs?

Many factories have established sample programs with clear policies that aren't always prominently advertised. Recognizing these programs helps structure requests according to factory preferences.

We've identified common sample program structures:

- Completely free samples for buyers with verified company status

- Sample fee waived against first order for serious prospects

- Free samples with paid shipping as a compromise approach

- Sample kits containing multiple standard items

- Virtual sample approval using detailed photos and videos

- Deposit systems refunded upon order placement

The China Sourcing Information Center reports that 60% of qualified manufacturers offer some form of free sampling for verified buyers. Our sourcing team maintains relationships with factories across different sample policy categories, matching clients with appropriate partners based on their specific sampling needs and order potential.

How to Minimize Factory Costs While Maximizing Value?

Factories evaluate sample requests based on cost versus potential value. Requests that demonstrate high potential value while minimizing factory investment receive the most positive responses and highest priority.

Strategic sample requests focus on standard materials, simple customization, and realistic evaluation timelines that reduce factory resource commitment while demonstrating genuine buying potential.

What Sample Specifications Reduce Factory Costs?

Complex customization, special materials, and rushed timelines significantly increase sample costs, reducing the likelihood of free sample approval. Strategic specification choices maintain evaluation value while minimizing factory investment.

We recommend these cost-minimizing approaches:

- Standard color requests from existing material inventory

- Stock material utilization rather than special orders

- Simple logo application instead of complex embroidery

- Standard size samples avoiding special pattern development

- Reasonable timelines accommodating normal production scheduling

- Bulkier shipping methods when time permits cost reduction

Manufacturing cost analysis from Production Cost Analytics shows that sample production costs decrease 40-60% when using standard materials and reasonable timelines. Our specification guidance helps clients request samples that provide meaningful evaluation while keeping factory costs manageable enough to justify free sample investment.

How Can You Demonstrate High Potential Value?

While minimizing factory costs, you must simultaneously demonstrate sufficient potential value to justify their sample investment. This balance requires clear communication of your business potential and evaluation seriousness.

We help clients demonstrate value through:

- Realistic quantity projections based on market research

- Clear evaluation process showing sample purpose

- Multiple product interest indicating larger potential orders

- Category specialization suggesting repeat business

- Market knowledge demonstrating understanding of pricing and quality

- Professional follow-up maintaining engagement after sample receipt

According to supplier relationship studies, buyers who provide detailed evaluation feedback receive 3x more free samples than those who don't follow up. Our clients maintain detailed sample tracking systems that demonstrate serious evaluation and provide valuable feedback to factories, building relationships that yield ongoing sample access.

What Sampling Etiquette Builds Strong Relationships?

Sample interactions establish the foundation for long-term manufacturing relationships. Proper etiquette demonstrates professionalism and respect for factory resources, creating partnership potential beyond single transactions.

Successful sampling etiquette includes timely communication, realistic expectations, proper acknowledgment of factory efforts, and transparent feedback regardless of sampling outcomes.

How Should You Communicate During Sample Production?

Regular, respectful communication during sample production demonstrates professionalism while providing opportunities to address potential issues before completion. However, excessive communication creates unnecessary factory workload.

We recommend structured communication protocols:

- Acknowledgement of sample approval with clear timeline understanding

- Single point of contact preventing communication confusion

- Scheduled update requests rather than constant checking

- Respect for time zones and cultural differences

- Clear modification requests if changes become necessary

- Appreciation for updates maintaining positive relationship

Research from Cross-Cultural Business Communications shows that manufacturers rate communication quality as equally important as order size when evaluating long-term partner potential. Our clients establish communication rhythms that demonstrate engagement without creating unnecessary factory workload.

What Feedback Protocol Encourages Ongoing Sampling?

Providing detailed, constructive sample feedback completes the sampling cycle and demonstrates respect for factory investment. Proper feedback creates learning opportunities for both parties and builds foundation for future sampling cooperation.

We've developed effective feedback systems:

- Structured evaluation criteria covering all relevant quality aspects

- Specific improvement suggestions rather than general complaints

- Photographic documentation of any issues encountered

- Market perspective explaining why changes are needed

- Appreciation for strengths alongside improvement areas

- Clear next steps indicating continued interest or polite closure

The International Apparel Federation identifies sample feedback as a critical relationship-building opportunity. Our clients provide feedback that helps factories improve their products while demonstrating the professional approach that encourages ongoing sample cooperation and priority treatment.

Conclusion

Getting free hat samples from Chinese factories requires balancing factory costs with demonstrated buyer value through professional requests, appropriate factory selection, strategic specifications, and proper relationship-building etiquette. Successful sampling establishes the foundation for manufacturing relationships that deliver long-term competitive advantages.

Approaching sampling as a collaborative process rather than a transactional request dramatically increases success rates while building supplier relationships that extend far beyond initial sample acquisition. The most successful importers view samples as mutual investment rather than one-sided benefit.

Ready to develop an effective sampling strategy for your hat business? Contact our Business Director Elaine to discuss how our manufacturer relationships and sampling expertise can accelerate your product development while minimizing costs. Her email is elaine@fumaoclothing.com. Let's build your sampling approach that delivers both immediate samples and long-term manufacturing partnerships.