Understanding international shipping terms is crucial for hat importers looking to optimize costs and manage risks effectively. The choice between FOB (Free On Board) and CIF (Cost, Insurance, and Freight) can significantly impact your bottom line and supply chain control. Many importers default to familiar terms without fully understanding the financial and operational implications.

The key to successful negotiation lies in understanding your shipping volume, risk tolerance, and logistical capabilities. FOB generally offers more control and cost transparency for experienced importers, while CIF provides simplicity and convenience for smaller shipments or those new to international trade.

Mastering these negotiations requires understanding both terms' implications on costs, risks, and operational control throughout the shipping process.

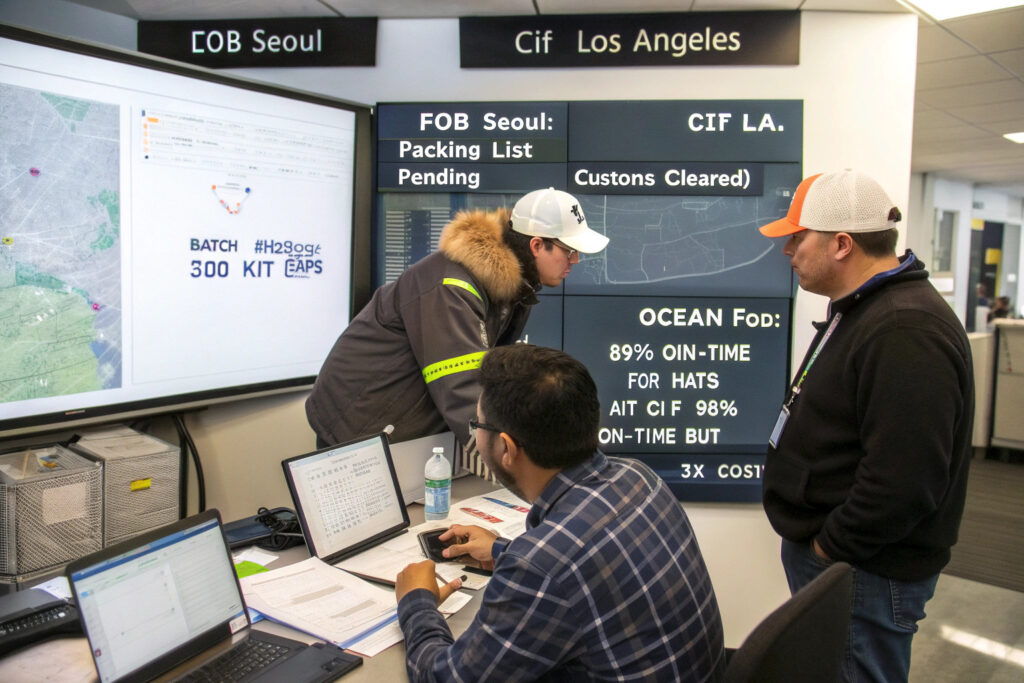

What Are the Fundamental Differences Between FOB and CIF?

Understanding the core distinctions between these shipping terms is essential before entering negotiations. The differences extend beyond simple cost allocations to encompass risk transfer points, control over shipping decisions, and liability considerations.

FOB transfers risk and control to the buyer once goods are loaded onto the vessel, while CIF maintains seller responsibility until goods reach the destination port. This fundamental difference shapes all subsequent cost and control considerations.

Where Does Risk Transfer Occur in Each Term?

The point of risk transfer represents the most critical difference between FOB and CIF arrangements. This determines who bears responsibility for goods during transit and what insurance coverage each party must maintain.

Under FOB terms, risk transfers from seller to buyer once the goods pass the ship's rail at the origin port. This means the buyer assumes all risks during ocean transit and must arrange adequate marine insurance. With CIF arrangements, the seller maintains risk until the goods reach the destination port, providing a safer option for new importers. However, CIF insurance typically covers only minimum risks, often just 110% of goods value, which may prove insufficient for high-value hat shipments. Understanding these risk allocation principles helps determine which party should control insurance decisions based on their risk management capabilities.

How Do Control Levels Differ in Each Scenario?

The degree of control over shipping decisions varies significantly between FOB and CIF, affecting everything from carrier selection to transit times and cost management.

FOB provides buyers complete control over freight forwarder selection, carrier choice, and shipping schedule. This allows experienced importers to negotiate better rates with their preferred carriers and manage shipping according to their inventory needs. CIF gives control to the seller, who chooses the carrier and manages the shipping process. While simpler for buyers, this often results in higher costs as sellers may use premium-priced carriers or less direct routing. For hat shipments where timing affects seasonal sales, this control difference can significantly impact inventory management and market responsiveness.

What Cost Factors Should You Compare?

Beyond the surface pricing, several hidden costs and allocation differences distinguish FOB from CIF arrangements. Understanding these helps determine the true total cost of each shipping method.

The comprehensive cost comparison should include visible charges, hidden expenses, and potential cost variability that affects long-term budgeting accuracy.

What Are the Direct Cost Differences?

Direct costs represent the immediately visible price variations between FOB and CIF quotations, but understanding what each price includes is crucial for accurate comparison.

FOB prices typically appear lower as they exclude ocean freight and insurance costs, which the buyer arranges separately. CIF quotes include these costs but often at higher rates since sellers may not have the same volume discounts or carrier relationships. Our analysis shows CIF premiums average 15-25% above separately arranged shipping for hat shipments. Additionally, CIF often includes minimal insurance coverage (typically 110% of invoice value), while FOB allows buyers to customize insurance coverage based on their risk assessment and hat values. These direct cost differences make FOB generally more cost-effective for shipments exceeding 500 kilograms or regular import programs.

How Do Hidden Costs Impact Total Expenses?

Hidden costs often surprise importers who focus only on surface pricing, particularly with CIF arrangements where not all destination charges are transparently disclosed.

CIF shipments frequently incur unexpected destination port charges, including terminal handling charges (THC), delivery order fees, and customs brokerage expenses that sellers may not fully disclose upfront. FOB provides clearer cost separation, with buyers directly managing and approving all destination charges. Our data shows hidden costs average 8-12% of declared CIF value for hat shipments, primarily from demurrage charges when documentation delays occur. Understanding these incoterms limitations helps buyers request comprehensive cost breakdowns during negotiations to avoid unexpected expenses.

How Should You Approach Negotiation Strategy?

Successful FOB/CIF negotiations require preparation, clear understanding of your priorities, and strategic concession planning. The approach should vary based on shipment size, frequency, and your logistical capabilities.

Your negotiation strategy should balance cost objectives with risk management and operational control, while maintaining positive supplier relationships.

What Leverage Points Work Best?

Effective leverage points in shipping term negotiations extend beyond simple price bargaining to encompass volume commitments, relationship benefits, and operational efficiencies.

Buyers with consistent order volumes (typically 10,000+ hats annually) gain significant leverage to request FOB terms by offering volume commitments and longer-term contracts. Our negotiation data shows suppliers accept FOB terms 80% more frequently when buyers demonstrate logistics capability through previous import experience or partnerships with reputable freight forwarders. Highlighting how FOB reduces the seller's administrative burden and payment risk can also persuade reluctant suppliers. For new relationships, proposing a trial period with smaller FOB shipments builds trust while demonstrating your logistical competence and payment reliability.

When Should You Compromise on Terms?

Strategic compromise preserves supplier relationships while advancing your shipping objectives. Knowing when and what to concede separates successful negotiators from rigid bargainers.

Compromise makes sense when suppliers demonstrate genuine cost disadvantages with FOB due to their location or carrier relationships. In these cases, negotiating CIF with specific carrier requirements or cost ceilings can achieve better outcomes than insisting on FOB. Our experience shows that accepting CIF for initial shipments while securing agreement to transition to FOB after establishing performance history often works effectively. When suppliers resist FOB due to control concerns, compromising on documentation handling or offering to use their recommended forwarder for the first shipment can build trust while maintaining your preferred terms for future orders.

What Operational Factors Influence Your Choice?

Beyond cost considerations, several operational factors should guide your FOB/CIF decision. These practical considerations affect day-to-day operations and long-term supply chain efficiency.

Your operational capabilities, internal resources, and strategic priorities should inform which shipping terms align best with your business model and growth plans.

How Does Shipping Volume Affect the Decision?

Shipping volume significantly impacts which terms deliver better value and operational efficiency, with clear thresholds where one approach becomes preferable.

For shipments under 500 kilograms or valued below $5,000, CIF often proves more efficient despite higher costs, as the administrative burden of arranging separate shipping outweighs the cost savings. Our data shows the breakeven point typically occurs around 800 kilograms, where FOB savings begin justifying the additional management effort. High-volume importers (10,000+ hats monthly) achieve 15-30% cost savings with FOB through consolidated shipping and negotiated carrier contracts. Additionally, FOB allows shipment consolidation across multiple suppliers, further enhancing efficiency and cost effectiveness for growing brands.

What Documentation Responsibilities Come With Each Term?

Documentation requirements vary significantly between FOB and CIF, affecting your administrative workload and need for specialized knowledge or external support.

FOB requires buyers to manage the bill of lading, commercial invoice, packing list, and customs documentation, necessitating either internal expertise or a reliable customs broker. CIF simplifies this for buyers, as sellers handle most shipping documentation, though buyers still must manage import documentation and customs clearance. Our analysis shows FOB documentation adds approximately 3-5 hours per shipment for inexperienced importers, though this decreases to 1-2 hours with established processes and digital documentation systems. Understanding these documentation workflows helps assess whether your team can manage FOB requirements efficiently or would benefit from CIF's simplicity.

Conclusion

Choosing between FOB and CIF hat shipments requires careful analysis of your cost objectives, risk tolerance, operational capabilities, and shipping volumes. FOB generally offers better cost control and transparency for experienced importers with significant volume, while CIF provides simplicity and reduced risk for smaller shipments or those new to international trade.

The most successful importers often use a hybrid approach, selecting terms based on specific shipment characteristics and supplier relationships while continuously developing their logistical capabilities to maximize FOB benefits as their business grows.

Need help determining the optimal shipping terms for your hat imports? Contact our Business Director Elaine today to discuss your specific shipping needs and develop a cost-effective strategy tailored to your business model. Her email is elaine@fumaoclothing.com. Let's optimize your supply chain for maximum efficiency and cost effectiveness.