The boutique store landscape thrives on uniqueness, where offering exclusive products is key to attracting discerning customers. Many boutique owners and independent brand managers want to offer their own line of distinctive knitted hats but are deterred by the perceived requirement of placing massive, risky inventory orders. You might wonder if there's a viable path between generic wholesale and overwhelming custom production.

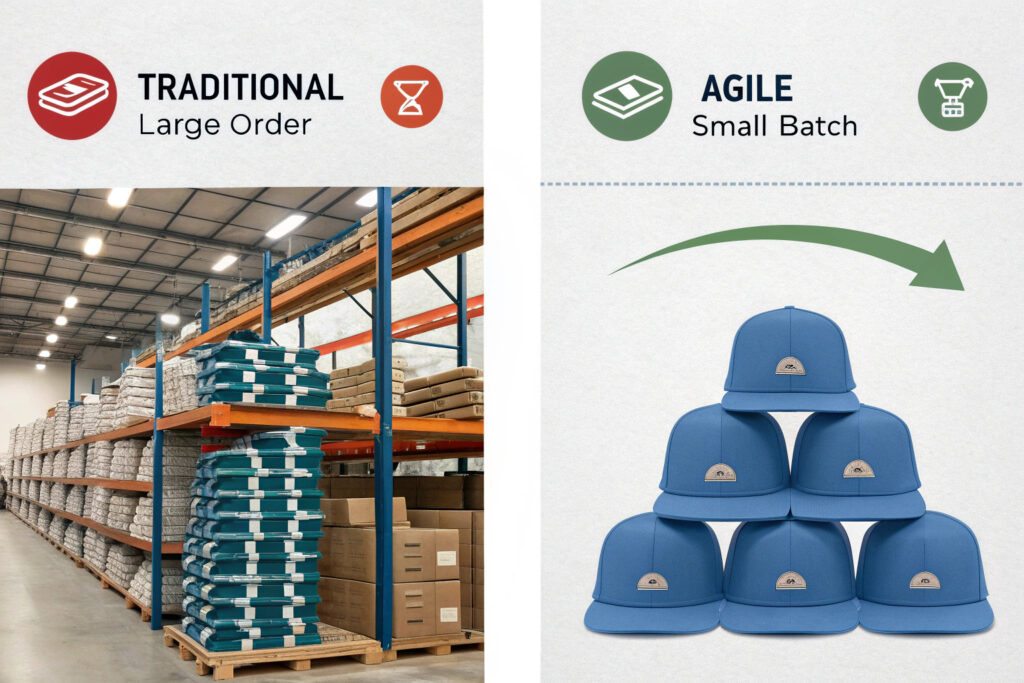

The answer is a definitive yes. Small-batch customization of knitted hats is not only possible but has become a strategically vital service for agile manufacturers. This approach allows boutiques to launch exclusive collections, test new designs with minimal risk, and build a strong, unique brand identity. The key lies in partnering with a supplier whose business model is built around flexibility and low minimum order quantities.

Gone are the days when custom knitwear was the exclusive domain of large brands with towering order volumes. Modern supply chains and production technologies have evolved to make small-batch runs commercially viable and creatively rewarding for smaller retailers. Let's explore how this process works and how it can become a cornerstone of your boutique's success.

Why Is Small-Batch Customization a Strategic Advantage for Boutiques?

Embracing small-batch production transforms a potential manufacturing hurdle into a significant business advantage. This model directly addresses the core operational and financial challenges faced by independent retailers, turning constraints into opportunities for growth and brand development.

How Does It Directly Reduce Financial Risk?

The most immediate benefit is a dramatic reduction in inventory risk and an improvement in cash flow. Placing an order for hundreds of identical units ties up substantial capital and commits valuable storage space. For a boutique operating with lean margins, this represents a major financial vulnerability. Small-batch production, with Minimum Order Quantities (MOQs) that can start from 50 to 100 pieces per style, lowers the initial investment barrier. This means you can invest in a greater variety of designs with the same budget, quickly respond to sales data, and avoid being burdened by slow-moving stock. This agile approach mirrors the just-in-time inventory principles that allow brands to be more responsive and financially resilient.

How Does It Foster Brand Uniqueness and Customer Loyalty?

Beyond the numbers, small-batch customization is a powerful brand-building tool. It empowers you to create exclusive designs that customers cannot find anywhere else. You can experiment with special yarn blends like organic cotton or recycled fibers, incorporate custom details such as branded leather patches or unique pompoms, and develop a cohesive color story for your store. This level of personalization allows you to tell a compelling story about craftsmanship, attention to detail, and exclusivity. By offering limited-edition collections or seasonal "drops," you can generate excitement, encourage repeat visits, and build a loyal customer base that values your unique product offering over generic alternatives.

What Are the Pathways to Sourcing Custom Knitwear in Small Batches?

Understanding the different avenues for production is crucial to finding the right partner for your brand's specific needs, scale, and creative vision. The landscape offers several distinct options, each with its own balance of control, capacity, and cost.

What Does Partnering with a Small-Batch Manufacturer Involve?

This is often the most practical and scalable route for boutiques aiming for consistent quality and commercial viability. These specialized manufacturers structure their operations to cater to lower volumes, offering services from Original Equipment Manufacturer (OEM) production—where they manufacture your precise design—to Original Design Manufacturer (ODM) support, where they can help develop designs based on your concepts. The key is to identify partners who explicitly advertise low MOQs and possess a portfolio demonstrating work with emerging or independent brands. This path provides a professional balance of creative input, technical expertise, and reliable output.

Is On-Demand Decoration a Good Starting Point?

For boutiques looking to test the waters of customization with minimal commitment, on-demand printing and embroidery services present a low-risk entry point. These services allow you to apply your custom logo or graphic design to pre-made, blank knitted hats. The primary advantage is an extremely low minimum order, sometimes as low as a single piece, which is perfect for validating a design idea or fulfilling a one-off custom request. The limitation is that you are only customizing the surface decoration, not the hat's fundamental structure, fit, or knit fabric. For boutiques at Shanghai Fumao Clothing, we often recommend this as a complementary service or a first step before embarking on a fully custom knit project.

How Do You Prepare for and Manage a Successful Production Partnership?

Transitioning from idea to finished product requires clear planning and professional communication. Being well-prepared not only streamlines the process but also establishes your credibility as a serious partner in the eyes of a manufacturer.

What Essential Materials Should You Prepare?

Preparation is the foundation of a smooth production journey. Before contacting potential suppliers, gather the following:

- Technical Sketches or Mockups: Clear visual references, whether digital renders or annotated drawings, that communicate your design intent.

- A Development Budget: Allocate funds specifically for sampling, which is a non-negotiable and invaluable phase.

- Target Cost Per Unit: Have a realistic understanding of your target retail price and the cost you can afford.

- Ideal Timeline: Define your launch goals but remain flexible to accommodate standard production lead times.

Compiling these elements into a basic "tech pack" demonstrates your professionalism and helps the manufacturer provide an accurate and timely quote.

What Are the Most Important Questions to Ask a Potential Supplier?

To identify a truly collaborative partner, move beyond basic questions about price and MOQ. Engage in a deeper dialogue by asking:

- "Can you explain your sampling process, including the typical timeline and costs for prototype and pre-production samples?"

- "What is your experience with the specific yarn types or knitting techniques (like jacquard or cable knit) I wish to use?"

- "How do you manage quality control for small-batch orders, and what are your inspection procedures?"

- "Can you share examples of or references from other small or boutique brands you have successfully partnered with?"

- "What are the options for packaging and labeling to align with my brand's aesthetic?"

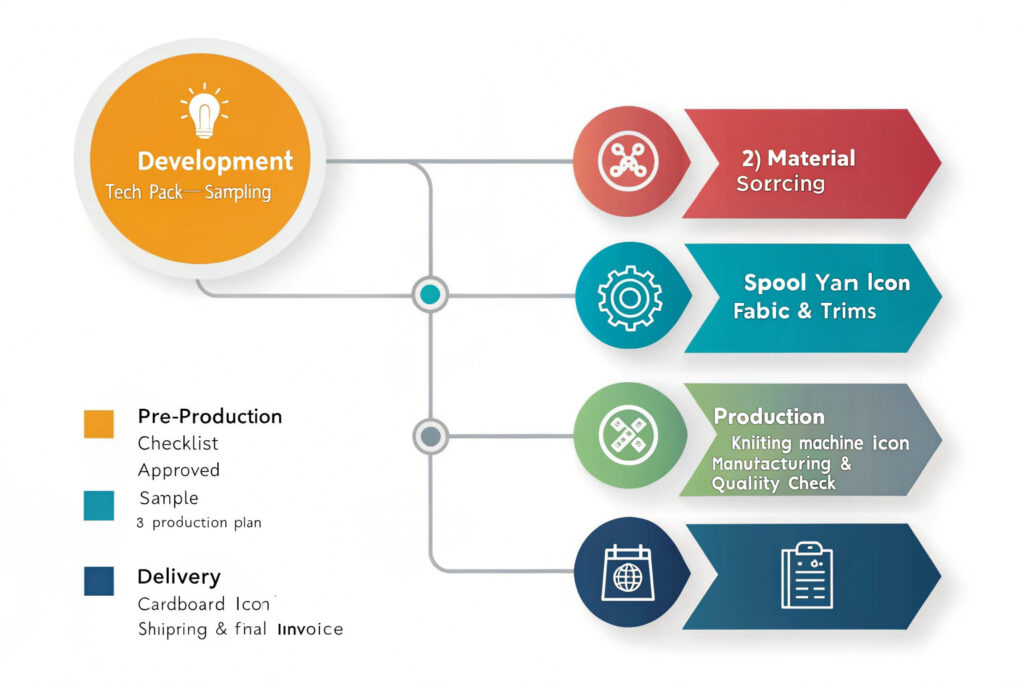

What Does the Step-by-Step Production Process and Cost Structure Look Like?

A clear understanding of the standard workflow and cost components will help you navigate the custom production process with confidence and avoid unexpected surprises.

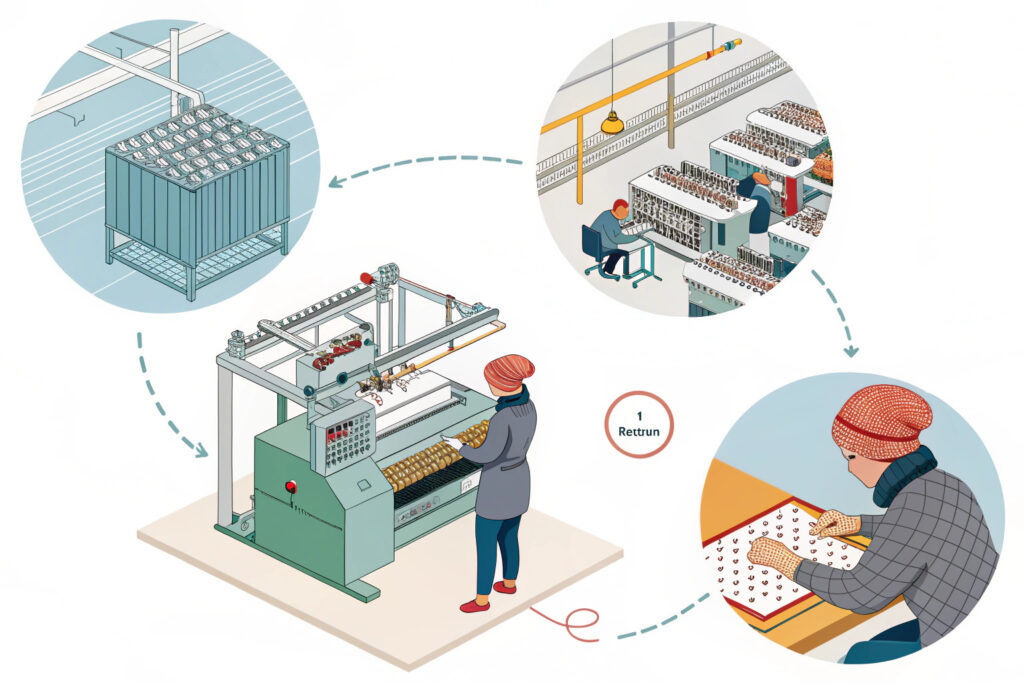

Why Is the Sampling Phase Non-Negotiable?

The sampling phase is the most critical investment you will make. It typically begins with a prototype sample, created to evaluate the design, fit, and materials. This stage usually involves 1-3 revisions to refine every detail. Once approved, a pre-production sample is made using the exact materials and methods planned for bulk production. This sample serves as the final contract between you and the manufacturer—the quality benchmark against which your entire order will be measured. Skipping or rushing this step significantly increases the risk of receiving bulk goods that do not meet your expectations.

How Are Costs Typically Broken Down for a Small Batch?

For small-batch orders, the cost per unit is understandably higher than for mass production due to setup costs being spread over fewer items. A transparent cost breakdown usually includes:

- Development and Setup Fees: Covers pattern creation, machine programming, and sampling labor.

- Material Costs: The price of yarn, as well as any custom labels, tags, or branded trims.

- Manufacturing Costs: The labor and overhead for knitting, sewing, finishing, and quality inspection of each hat.

- Logistics Costs: Expenses for shipping, import duties, and insurance from the factory to your location.

A reliable partner, such as Shanghai Fumao Clothing, will provide a detailed and transparent quotation outlining each of these components.

Conclusion

Customizing knitted hats in small batches is a powerful and accessible strategy for boutique stores to differentiate themselves and build a resilient, customer-centric brand. By leveraging the advantages of reduced financial risk, enhanced creative control, and the ability to offer genuine exclusivity, boutiques can turn their product vision into a tangible competitive edge. The journey requires careful planning, clear communication with the right manufacturing partner, and a commitment to the collaborative sampling process.

If you are ready to explore the creation of an exclusive, small-batch knitted hat collection that captures the essence of your boutique, we are here to help. For a detailed discussion on bringing your unique designs to life, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's collaborate to craft something exceptional for your customers.