Have you ever wondered what's inside the brim of a baseball cap? How does it maintain that perfect, stiff curve for years without breaking or becoming floppy? Is it just cardboard? (Hint: in a quality cap, absolutely not!) The creation of a stiff, durable brim is a critical manufacturing process that separates a high-quality cap from a cheap, disposable one.

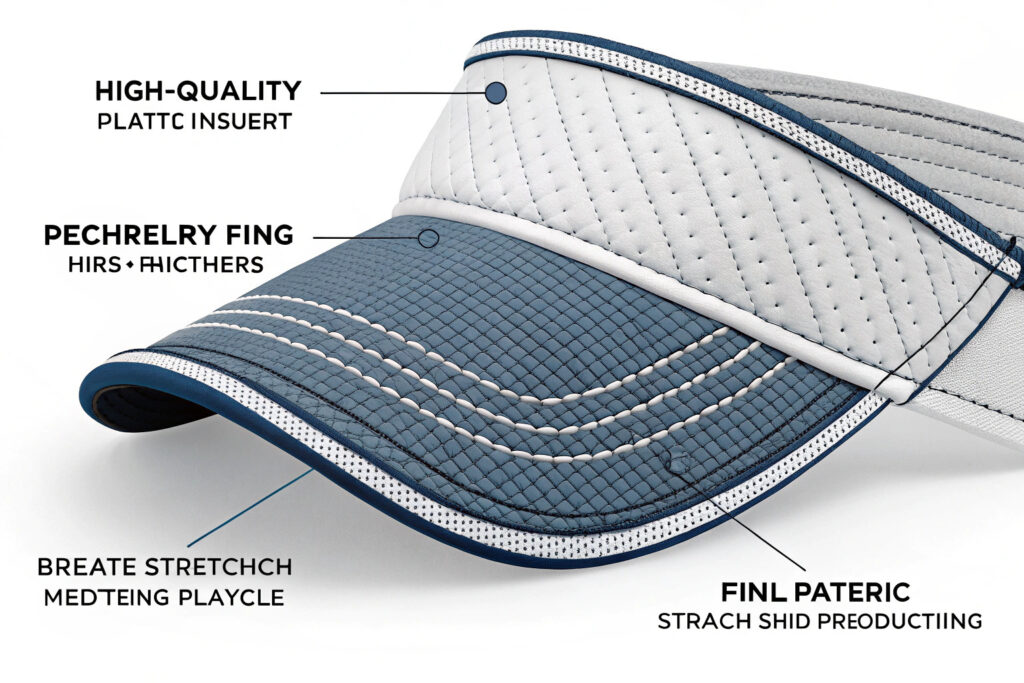

The secret to a stiff and durable brim lies in a high-quality plastic visor insert, which is sandwiched between two layers of fabric and then stitched together with multiple rows of high-density stitching to create a strong, unified, and perfectly shaped final component. It's a precise combination of the right core material and the right construction technique.

As the owner of Shanghai Fumao Clothing, I want to walk you through the three crucial stages of this process. Understanding how the brim is constructed will give you a much deeper appreciation for what makes a truly great cap.

What is the "Secret Ingredient" Inside the Brim?

Let's start by answering the most common question: what is actually inside the brim? In the past, and in very low-quality caps today, the insert might have been made from cardboard or a cheap, brittle plastic. This is why old hats would lose their shape or even disintegrate if they got wet.

So, what do modern, high-quality caps use? The industry standard core material is a specialized plastic visor insert, most commonly made from Polyethylene (PE) or Polypropylene (PP). These materials are chosen for a very specific set of properties that make them perfect for the job.

Isn't choosing this core material the most important decision in the entire process? It is the literal foundation of the brim.

Why is Polyethylene the Perfect Material?

What makes this specific type of plastic so special?

- Durability & Flexibility: High-quality PE plastic has the perfect balance. It is stiff enough to hold a curve but flexible enough to be bent without snapping or creasing. It has a "plastic memory," meaning it will return to its intended shape.

- Waterproof: This is a huge advantage over cardboard. A PE insert is completely waterproof. You can wash the cap or get caught in the rain without any fear of the brim turning to mush.

- Lightweight: Despite its strength, it is very lightweight, ensuring the cap is comfortable to wear.

- Consistency: It can be manufactured to a precise, uniform thickness, which is crucial for a consistent final product. This is a key part of our quality control process.

How is the Visor Insert Shaped?

How do we get that perfect curve? The plastic inserts are created using a process called die-cutting. A large sheet of the PE plastic is fed into a machine, and a custom-shaped metal die (like a heavy-duty cookie cutter) presses down to cut out the precise visor shape. The inserts are typically cut flat and are flexible enough to be curved during the final assembly stages. This allows us to use the same insert for both flat-brim and curved-brim styles.

How Do We Construct the "Sandwich"?

Once we have our high-quality plastic insert, the next stage is to create the "sandwich." The brim of a cap is not a single piece of fabric; it's a carefully constructed assembly of three layers:

- The Top Fabric Layer: This is the same fabric as the rest of the cap's crown.

- The Plastic Visor Insert: The "secret ingredient" we just discussed.

- The Bottom Fabric Layer: This can be the same fabric as the top, or a different color for a contrast effect (often called an "under-visor").

How are these layers combined? This is done through a combination of lamination and sewing.

Isn't this assembly process where the skill of the factory really shows? A poorly assembled brim will look lumpy and unprofessional.

What is the Role of Lamination?

How do you prevent the fabric from slipping around on the plastic? Before sewing, we often use a thin layer of adhesive to temporarily bond the fabric to the plastic insert. This ensures that the fabric lies perfectly flat and smooth against the insert, with no air bubbles or wrinkles. This step is crucial for creating that clean, premium look, especially on the top surface of the brim.

How is the Sandwich Sewn Together?

What is the first sewing step? The three layers are stacked, and then a single stitch is sewn around the outer curved edge to join them together. The excess fabric is then trimmed away. At this point, we have a raw, semi-finished brim. But the real magic of its durability comes from the next, most visible step: the decorative stitching.

Why is the Stitching on the Brim So Important?

Have you ever counted the number of stitches on the brim of a baseball cap? There are typically between four and eight parallel rows of stitching that run along the curve of the brim. Are these stitches just for decoration? No. They play a critical structural role.

What is the function of these stitches? This dense pattern of stitching does three things simultaneously:

- It permanently quilts the top fabric, the plastic insert, and the bottom fabric together into a single, unified piece.

- It adds significant rigidity and strength to the entire structure.

- It helps to "set" the curve of the brim, encouraging it to hold its shape.

This stitching is the final step that transforms the "sandwich" into a stiff, strong, and incredibly durable component.

How is This Stitching Done So Perfectly?

How do you get the lines so parallel? We use specialized sewing machines that are fitted with a "guide." This guide ensures that each row of stitching is perfectly spaced from the previous one. The operator guides the brim along this edge, and the machine does the work of creating those flawless, evenly spaced lines. The number of rows of stitching is a key detail specified in the product's tech pack.

Does More Stitching Mean a Stiffer Brim?

Generally, yes. A brim with eight rows of stitching will feel slightly stiffer and more robust than a brim with just four rows. The number of stitches is often a design choice. A classic, retro-style cap might have fewer rows, while a modern, on-field athletic cap will almost always have the maximum number of rows to provide the most strength and a crisp, rigid look. This is a detail that brands can specify to achieve their desired aesthetic and feel.

Conclusion

So, how do we make a baseball cap brim stiff and durable? Is it a simple, one-step process? As you can see, it's a carefully engineered system.

It's a combination of starting with the right core material—a high-quality, waterproof plastic insert—then skillfully constructing a three-layer "sandwich" with the outer fabric, and finally, locking it all together with multiple rows of dense, structural stitching.

It's this three-stage process that creates a brim you can curve to your liking, get wet, and wear for years without it losing its essential shape and character. The next time you pick up a high-quality baseball cap, take a moment to appreciate the hidden engineering that went into creating its most defining feature.

Understanding these details is what separates a good product from a great one. If you're looking for a partner who obsesses over these details to build the best possible headwear for your brand, we are ready to help. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com.