As a wholesale buyer or brand developer, you're constantly looking for ways to extend the selling season of your most popular products. You see the enduring appeal of the straw hat, but you've always mentally filed it under "Spring/Summer Only." You're likely wondering: is it possible to break the straw hat out of its seasonal prison? Can it be engineered to handle more than just a perfect, sunny day, making it a viable product for year-round wholesale?

Yes, absolutely. A straw hat can be made significantly more weather-resistant through a combination of advanced material treatments, innovative construction techniques, and by blending traditional straw with high-performance materials. By applying water-repellent coatings, reinforcing the structure, and incorporating technical linings, you can create a "performance straw hat" that withstands light rain, wind, and cooler temperatures, dramatically expanding its marketability into the spring, fall, and even mild winter seasons.

At my company, Shanghai Fumao Clothing, we've spent over two decades pushing the boundaries of traditional hat making. The idea of a "four-season" straw hat isn't a fantasy; it's an engineering challenge that we solve by treating the straw not as a delicate fiber, but as a base material to be enhanced. For a wholesale client, this opens up a massive opportunity: to offer the timeless aesthetic of a straw hat with the practical resilience of modern outdoor gear. Let's explore the specific techniques used to create this new category of weather-resistant headwear.

How Do You Make Straw Resistant to Water?

The single greatest weakness of a traditional straw hat is its vulnerability to water. Rain can cause the straw to swell, lose its shape, and even begin to rot. The key to weather-resistance is to prevent water from ever saturating the fibers in the first place.

The most effective method is to treat the straw with a hydrophobic (water-repellent) coating. This is a specialized, invisible finish that is applied to the finished hat body, causing water to bead up and roll off rather than soak in. This is the primary technology that transforms a straw hat into an all-weather accessory.

What Kind of Coatings Are Used?

There are two main types of treatments. The first is a silicone-based spray. This is a very effective and common method where a fine mist of silicone is applied to the hat, creating a durable, water-repellent barrier. The second, more advanced option is a fluoropolymer-based finish (similar to the technology used in Scotchgard™ or Teflon™). This treatment not only repels water but also helps to resist oil and stains, making the hat more durable overall. When sourcing, you should specify that you require a "Durable Water Repellent (DWR) finish" applied to the hat.

Does the Type of Straw Matter?

Yes, the base material plays a huge role. While treatments can be applied to most types of straw, some materials are naturally more resilient. Toyo straw, which is made from rice paper, is often coated and shellacked, giving it a smooth, slightly stiff finish that is inherently more water-resistant. Raffia straw, which contains natural resins, has a degree of innate flexibility and water resistance. However, for the best performance, starting with a quality straw and adding a DWR finish is the winning combination.

How Do You Make a Straw Hat Wind-Resistant and Crush-Proof?

A gust of wind can easily send a flimsy straw hat flying, and packing one for a trip can result in a permanently creased or crushed crown. A true year-round hat needs to be more robust and travel-friendly.

The solution is to reinforce the hat's structure, primarily through a wired brim and a crushable, reinforced crown. These features ensure the hat holds its shape in the wind and can bounce back after being packed in a suitcase.

What Is a "Memory Wire" Brim?

To combat the wind and add durability, we sew a flexible "memory wire" into the outer edge of the brim. This wire is typically a plastic-coated metal that is strong but pliable. It serves two purposes: 1) It adds weight and stiffness to the brim, making it less likely to be flipped up by a gust of wind, and 2) It allows the wearer to shape the brim and, more importantly, to easily reshape it if the hat gets crushed. This is a key feature of a high-quality, travel-ready hat.

How Do You Create a "Crushable" Crown?

A crushable hat is not about using weaker straw; it's about using a higher quality, more flexible grade of straw (like genuine Panama straw or high-grade raffia) and constructing the hat with a slightly less rigid blocking process. Some designs also incorporate an invisible silicone or polymer reinforcement at the pinch point of the crown (on a fedora, for example). This allows the crown to be compressed and bounce back to its original shape without developing a permanent, sharp crease that would eventually break the straw fibers.

How Can You Adapt a Straw Hat for Cooler Temperatures?

To make a straw hat a true three-season or four-season item, you need to address temperature. A standard, unlined straw hat is designed for ventilation and offers no warmth.

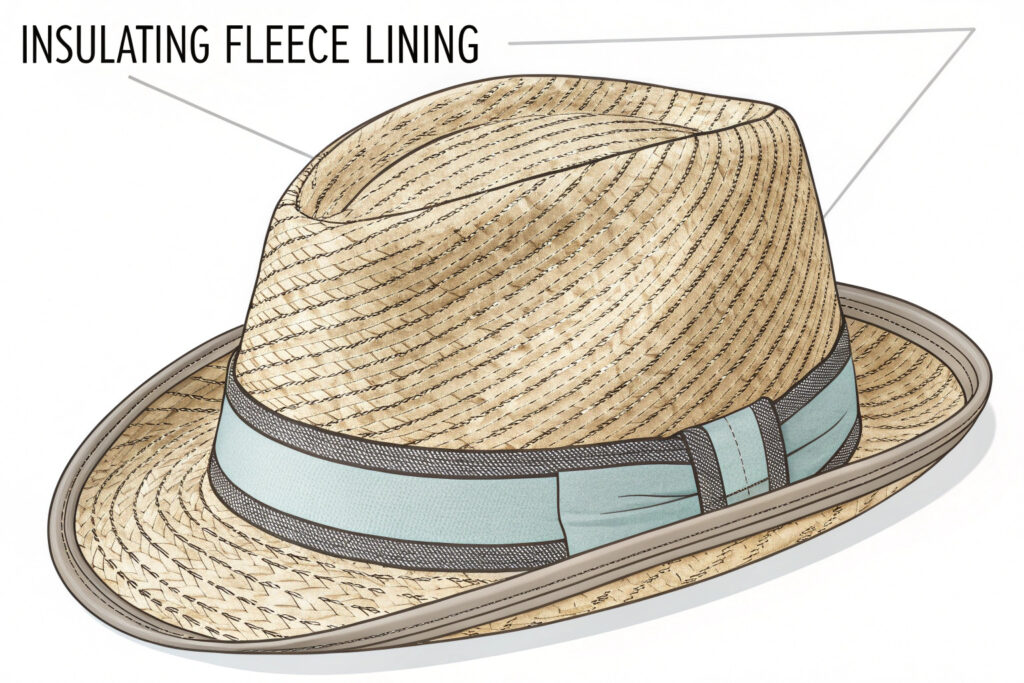

By incorporating technical and performance linings, you can add a significant amount of comfort and warmth, making the hat suitable for crisp fall days or mild winter weather.

What Are the Best Lining Materials for Warmth?

For a fall/winter version of a straw hat, you can specify a lightweight microfleece or a soft flannel lining. These materials are excellent at trapping a layer of warm air, providing insulation without adding significant bulk. A fleece-lined straw fedora is a surprisingly warm and comfortable accessory for a cool, sunny autumn day.

What About a Performance Sweatband?

The inner sweatband is another opportunity to enhance performance. Instead of a simple grosgrain ribbon, you can specify a moisture-wicking performance sweatband, similar to what's used in athletic caps. A brand like Coolmax® makes sweatbands that pull moisture away from the skin, which is valuable in both hot and cool weather. In the summer, it manages sweat. In the cooler months, it prevents the damp, clammy feeling that can make you feel colder. This is a small detail that significantly improves the hat's year-round comfort.

How Do You Verify and Market a Weather-Resistant Straw Hat?

You've created a technical masterpiece. Now, how do you communicate its value to your wholesale clients and the end consumer? You need to test its performance and market its features clearly.

This involves simple, documented in-house testing and creating marketing materials that highlight the hat's specific weather-resistant features. Unlike a UPF rating, there isn't a single lab certification for "weather resistance," so it's about demonstrating the benefits.

How Do You Test the Features?

As a manufacturer, we perform a series of documented quality tests.

- Water Repellency: We use a standardized spray test (like AATCC Test Method 22) to rate how well the fabric beads water. We can provide photos and videos of this test to our clients.

- Crush Test: We repeatedly crush a sample hat (e.g., rolling it up, compressing it flat) and document its ability to return to its original shape without damage.

- Wind Test: While harder to quantify, we can use a high-powered fan to demonstrate the stability of a wired brim versus a non-wired brim.

How Do You Market It for Year-Round Sales?

The key is to shift the narrative. Don't just call it a "straw hat." Call it a "Performance Straw Fedora" or an "All-Weather Safari Hat." Use your product descriptions, hang tags, and marketing campaigns to educate the customer about the specific features you've built in. Use phrases like:

- "Treated with a water-repellent finish to handle unexpected showers."

- "Features a crushable crown and shapeable wired brim, making it the perfect travel companion for any season."

- "A soft fleece lining adds a touch of warmth for crisp autumn days."

By doing this, you're not just selling a hat; you're selling a versatile, reliable, year-round piece of technical gear.

Conclusion

The notion of a straw hat as a summer-only item is officially outdated. Through the strategic application of modern technology—hydrophobic coatings, structural reinforcements like wired brims, and performance linings—it is entirely possible to create a durable, weather-resistant straw hat that is commercially viable for year-round wholesale. This new category of "performance straw" headwear meets the demands of consumers who value both timeless style and practical, four-season functionality. By engineering these features into your product and clearly marketing its benefits, you can unlock a new revenue stream and position your brand as an innovator in the headwear market.

If you are a wholesale brand looking to develop a line of weather-resistant, year-round straw hats, my team has the technical expertise and manufacturing capability to turn this concept into a reality. Please contact our Business Director, Elaine, at elaine@fumaoclothing.com to pioneer this exciting new category with us.