As a buyer for an outdoor supply store or a brand manager developing a new adventure gear line, your reputation rests on the quality of your products. You know your customers don't just wear your hats to look good; they depend on them for protection in rugged, unpredictable environments. You've probably had that nagging fear: what if the fabric on the thousands of hats you just ordered fades after one season, tears on the first branch it meets, or fails to protect your customer from a sudden downpour?

To verify the fabric durability of bulk cloth hats for outdoor use, you must implement a three-pronged strategy: 1) Specify the right technical fabrics from the outset, 2) Demand certified lab testing reports from your manufacturer for key performance metrics like tensile strength, abrasion resistance, and colorfastness, and 3) Conduct rigorous physical sample testing yourself before approving mass production.

I've spent more than two decades at Shanghai Fumao Clothing manufacturing headwear for some of the most demanding applications imaginable. I can tell you with certainty that "durability" isn't a vague marketing term; it's a measurable science. Verifying it isn't about hope; it's about process. For a bulk order, you cannot afford to discover a fabric's weakness after the product has shipped. Let's walk through the professional, systematic approach to ensuring the hats you sell are built to last.

How Do You Choose the Right Durable Fabric from the Start?

Verification begins at the very beginning: with fabric selection. You can't test durability into a weak fabric. You must choose materials that are inherently suited for the rigors of outdoor use. This means looking beyond simple cotton and into the world of technical textiles.

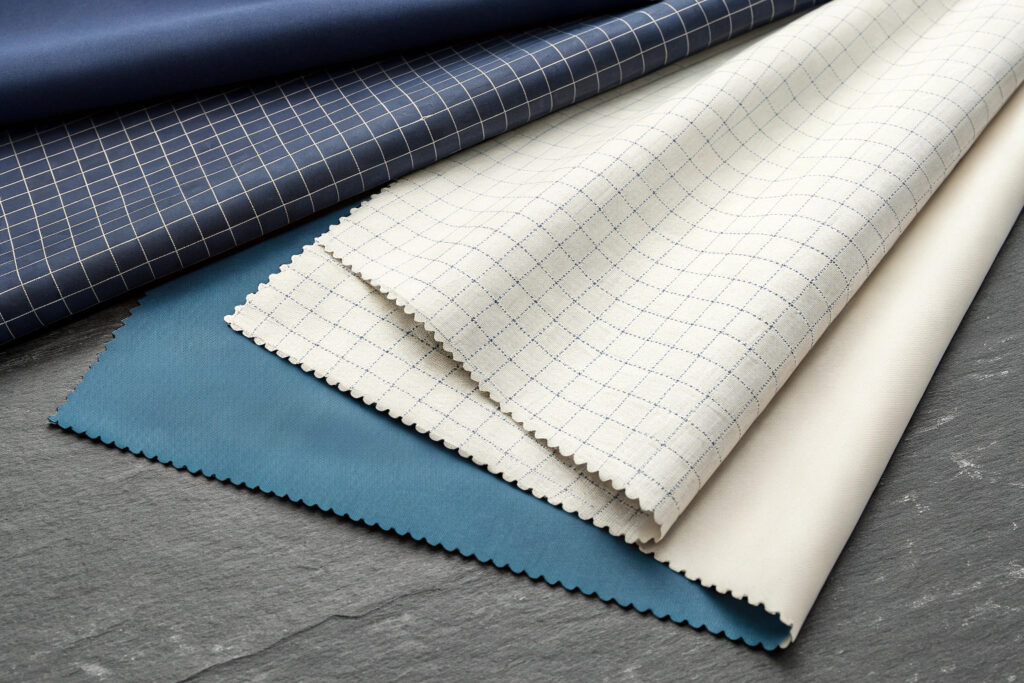

The best approach is to specify a fabric known for its performance characteristics. The most common and reliable choices for durable outdoor hats are nylon ripstop, cotton canvas, and specialized synthetic blends. Each offers a different balance of strength, weight, and breathability. Starting with one of these proven materials is the first and most important step in ensuring a durable final product.

What Is Nylon Ripstop and Why Is It So Popular?

Nylon ripstop is a lightweight, synthetic fabric that has a special reinforcing technique. Thicker threads are interwoven in a crosshatch pattern, which creates the signature grid you can see and feel. This grid structure is the key to its durability: if the hat does get a small tear, the rip will stop at the next thick thread instead of continuing to tear across the entire fabric. This makes it incredibly strong for its weight, which is why it's a favorite for everything from tents to high-performance outdoor hats.

When Is Cotton Canvas the Right Choice?

For a more traditional, rugged aesthetic, nothing beats cotton canvas. This is a heavy-duty, plain-weave fabric known for its exceptional strength and abrasion resistance. Think of classic workwear jackets or durable duffel bags. A hat made from a high-quality, tightly woven canvas can withstand a tremendous amount of abuse. You can also get "waxed canvas," which is treated with paraffin wax to provide excellent water resistance, making it perfect for hats intended for use in wet, demanding climates.

What Specific Lab Tests Should You Demand?

Once you've selected your fabric, you cannot simply take the supplier's word for its quality. You must demand objective, scientific proof. This is where certified laboratory testing comes in. A reputable manufacturer will be able to provide you with test reports from an accredited lab (like SGS, Intertek, or a CNAS-certified facility) for the specific fabric batch being used for your order.

These tests replace subjective feelings about a fabric with hard data. The three most critical tests for outdoor hat durability are Tensile Strength, Abrasion Resistance, and Colorfastness to Light. These three data points will give you a clear, objective picture of how the fabric will perform in the real world.

How Is Tensile Strength Measured?

Tensile strength testing measures the force required to tear a fabric. A strip of the material is clamped into a machine and pulled from opposite ends until it rips. The result is measured in Newtons (N) or pounds-force (lbf). A higher number means the fabric is stronger and more resistant to tearing. For a durable outdoor hat, you should look for a robust tensile strength rating, which provides confidence that the hat won't easily tear if snagged on a branch. This is a standard test under methods like ASTM D5034.

Why Is Colorfastness to Light So Critical?

An outdoor hat spends its entire life exposed to the sun. Colorfastness to light measures a fabric's ability to resist fading when exposed to UV light. In the lab, a fabric sample is exposed to intense artificial light that simulates prolonged sunlight. The amount of fading is then graded on a scale, typically from 1 (very poor) to 5 (excellent) for apparel. For an outdoor hat, you should never accept a grade lower than 4. A grade of 3 means the color will noticeably fade after just one season of regular use, leading to unhappy customers and returns.

How Should You Conduct Your Own Physical Sample Testing?

Lab reports are essential, but they are no substitute for your own hands-on testing of a pre-production sample. This is your chance to simulate real-world use and abuse before you commit to a bulk order of thousands of pieces.

Your physical testing should be aggressive and practical. Don't just look at the sample; use it. Wear it. Abuse it. Try to make it fail. This tactile, real-world evaluation can reveal issues that lab reports might not, such as the strength of the stitching, the durability of components like snaps or buckles, and the overall feel of the product after being subjected to stress.

How Can You Test Abrasion and Stitching?

You don't need a Martindale machine to get a sense of abrasion resistance. Take the sample hat and vigorously rub a section of it against a rough surface, like a brick wall or the corner of a wooden desk, for 30 seconds. A poor-quality fabric will show immediate fuzzing or pilling. A good fabric will show little to no effect. Next, grab the hat on either side of a major seam (like where the brim meets the crown) and pull hard. Listen for any popping sounds, which indicate weak thread or poor stitch quality.

How Do You Perform a Simple Water Resistance and Colorfastness Test?

To test water resistance, sprinkle some water on the hat. Does it bead up and roll off (good), or does it immediately soak in and darken the fabric (bad)? For a quick colorfastness check, soak a corner of the hat in warm water for 20 minutes, then squeeze it out into a white bowl or onto a white paper towel. If you see any significant color bleeding into the water or onto the towel, it's a major red flag for poor dyeing, which often correlates with poor UV resistance.

How Do You Ensure the Bulk Order Matches the Approved Sample?

You've done your homework, approved the lab reports, and tortured the pre-production sample. It's perfect. Now, how do you ensure that the 10,000 hats you receive are made to the exact same standard?

This is where a clear manufacturing agreement and quality control process become critical. You need to have a "Golden Sample" or "Sealed Sample" that serves as the benchmark for the entire production run. You should also agree on an AQL (Acceptable Quality Limit) inspection standard with your manufacturer.

What Is the Role of the "Golden Sample"?

The "Golden Sample" is a pre-production sample that you have fully approved. You and your manufacturer both sign it and keep a version. This sample becomes the physical contract for the product's quality. Any product from the bulk production run that does not match this Golden Sample in terms of fabric, color, stitching, or construction can be considered a defect.

How Does an AQL Inspection Work?

AQL is a statistical method for quality control used for bulk orders. Instead of checking every single hat (which is impractical), an inspector will pull a random sample from the production lot and inspect them for defects. The AQL standard (e.g., AQL 2.5) defines how many minor and major defects are acceptable within that random sample. This process, often performed by a third-party inspection service before the goods leave the factory, provides a statistically reliable snapshot of the entire order's quality. It's your final insurance policy, ensuring the durability you verified in the sample has been successfully replicated in mass production.

Conclusion

Verifying the fabric durability of bulk outdoor hats is a systematic process, not a game of chance. It begins with selecting the right high-performance materials, is validated by demanding certified lab reports for key metrics like tensile strength, abrasion, and colorfastness, and is confirmed through your own rigorous physical testing of a pre-production sample. By locking in quality with a Golden Sample and using AQL standards for the final inspection, you create a chain of accountability that ensures the product you sell is worthy of your brand and the trust of your adventurous customers. This professional approach eliminates guesswork and protects your investment, your reputation, and your customers on their next great adventure.

If you are looking for a manufacturing partner who understands and embraces this level of quality control and transparency, my team is ready to help. We believe in building products that last. Please contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your next project.