As a key member of a Formula 1 pit crew, you operate in one of the most extreme and high-pressure workplaces on the planet. In a chaotic environment of intense heat, frantic activity, and split-second deadlines, every single piece of your gear must offer a competitive advantage. You've probably worn standard polyester or cotton caps that get soaked with sweat, feel heavy, and do little more than block the sun. But what if your cap could do more? What if it could actively help you stay cooler, safer, and more focused?

Graphene-infused baseball caps are ideal for F1 pit crews because they offer an unparalleled combination of passive thermal regulation, UV protection, and antimicrobial properties in an ultralightweight, durable package. The unique atomic structure of graphene allows it to dissipate heat away from the head, shield against harmful radiation, and inhibit bacterial growth, directly addressing the key environmental and physiological challenges of the pit lane.

For over two decades at my company, Shanghai Fumao Clothing, I have been at the forefront of integrating advanced materials into headwear. While we've worked with countless performance fabrics, nothing has the game-changing potential of graphene. For the high-stakes world of F1, where marginal gains determine winners and losers, a cap that actively manages heat and hygiene isn't a luxury; it's a vital piece of performance equipment. Let's break down the science that makes this revolutionary material a perfect fit for the pit crew.

How Does Graphene Provide Superior Thermal Regulation?

The F1 pit lane is an incredibly hot environment. You're surrounded by hot cars, blistering tarmac, and often located in sun-drenched climates like Bahrain or Singapore. Overheating is a serious risk that can impair cognitive function and slow reaction times—a disastrous outcome in a pit stop that lasts less than three seconds.

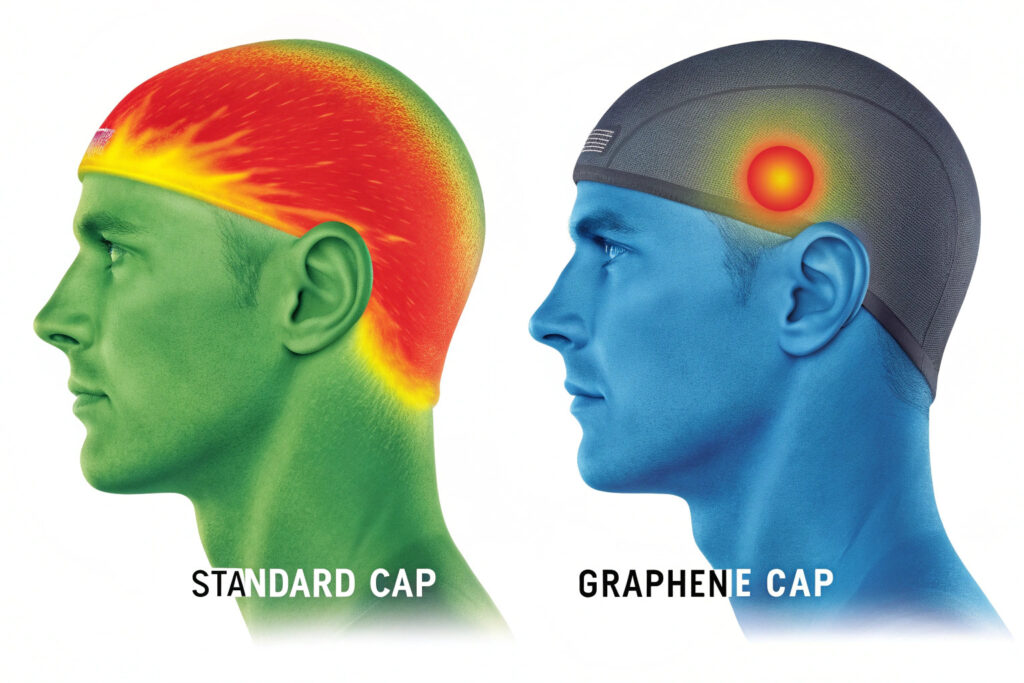

A graphene-infused cap acts as a passive heat sink for your head. Unlike standard fabrics that trap heat, graphene's unique 2D lattice structure is the most thermally conductive material ever discovered. It works by absorbing the heat your body generates and efficiently dispersing it across the entire surface of the cap, where it can be radiated away into the environment. This process helps to lower and stabilize the skin temperature of your head, keeping you measurably cooler and more comfortable under pressure.

What Is Thermal Conductivity and Why Does It Matter?

Thermal conductivity is a measure of a material's ability to transfer heat. Most fabrics, like cotton and polyester, are thermal insulators—they are good at trapping air and keeping you warm. Graphene is the opposite; it's a thermal superconductor. When the graphene-infused yarn in the cap comes into contact with your warm skin, it immediately pulls that heat energy away and spreads it out. This prevents the buildup of "hot spots" on your head, which is the primary cause of that stuffy, overheated feeling you get from a normal cap. This is a direct application of the principles of heat transfer to wearable technology.

How Does It Interact with Far-Infrared Radiation?

Your body naturally emits heat in the form of far-infrared (FIR) radiation. Graphene is exceptionally efficient at absorbing and re-emitting this energy. By absorbing the FIR energy from your head and radiating it outwards, the cap actively cools you. In colder conditions, this property can be reversed; the graphene can absorb FIR energy from the environment (like the sun) to provide warmth. This ability to dynamically regulate temperature based on the environment makes it a truly "smart" material, perfect for the fluctuating conditions of a race weekend.

What Other Performance Benefits Does Graphene Offer?

While thermal regulation is the headline feature, the benefits of graphene for a pit crew don't stop there. The unique properties of this "wonder material" address several other key challenges of the pit lane environment, including sun exposure, hygiene, and durability.

Graphene-infused fabrics provide a suite of built-in performance features that are highly desirable for any piece of technical apparel. These include powerful UV protection, natural antimicrobial and anti-odor properties, and exceptional strength and durability, all without the need for chemical coatings that can wash out over time.

How Does It Protect Against UV Radiation?

F1 races often take place under intense, direct sunlight. Prolonged UV exposure is a significant health risk. The carbon atoms in graphene are highly effective at absorbing the entire spectrum of UV radiation (UVA and UVB). When woven into a fabric, this provides a powerful, permanent barrier against the sun's harmful rays, typically achieving a UPF (Ultraviolet Protection Factor) rating of 50+, the highest possible. Unlike temporary chemical treatments, this protection is inherent to the material and will not degrade over time or with washing.

Why Are Antimicrobial Properties Important?

In a high-stress, high-sweat environment, bacteria can build up quickly on clothing, leading to unpleasant odors and potential skin irritation. Graphene's physical structure is naturally inhospitable to bacteria. The sharp edges of the graphene nanoplatelets can physically damage the cell membranes of microbes, preventing them from multiplying. This means the cap will stay fresher for longer, even after a long, hot race day. This built-in hygiene is a significant advantage for gear that is worn for extended periods under demanding conditions.

How Are Graphene Caps Manufactured?

You might be picturing a rigid, metallic hat. The reality is that a graphene cap looks and feels like a premium piece of performance apparel. The graphene is integrated at the fiber level, creating a soft, flexible, and comfortable textile.

The manufacturing process involves creating a graphene-infused yarn. This is typically done by blending graphene nanoplatelets into a polymer (like polyester or nylon) before it is extruded into a fiber. This masterbatch yarn is then woven or knitted into a fabric, which is then used to construct the cap. This method ensures that the graphene is permanently and evenly distributed throughout the material, guaranteeing consistent performance.

What Is Graphene-Infused Yarn?

The process starts with producing graphene oxide or graphene nanoplatelets from raw graphite. These microscopic particles are then mixed into a liquid polymer solution. This solution is then forced through a spinneret to create a continuous filament fiber. As the fiber solidifies, the graphene platelets are locked inside. This "dope-dyeing" style of integration is far superior to simply coating a finished fabric, as the properties become a permanent part of the yarn itself. At Shanghai Fumao Clothing, we partner with cutting-edge textile mills that specialize in producing these advanced composite yarns.

How Is the Cap Designed for a Pit Crew?

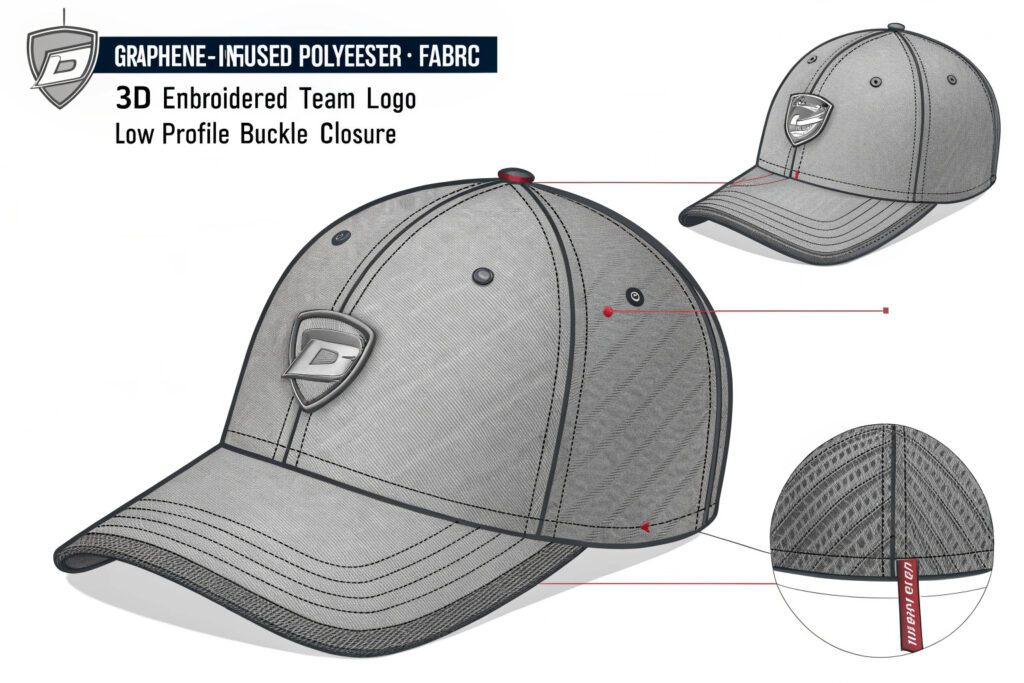

While the material is revolutionary, the design must still be functional for the specific user. For an F1 pit crew, the cap would be a classic six-panel baseball cap style, allowing for prominent team and sponsor branding on the front and sides. It would feature a pre-curved brim with a dark underside to reduce glare from the track and overhead lights. The closure would be a low-profile, adjustable system, like a Velcro strap or a sleek buckle, that won't snag on other equipment. The design combines the high-tech fabric with a proven, practical silhouette, a core principle of good industrial design.

How to Source and Customize These High-Tech Caps?

Sourcing graphene-infused apparel is not like ordering standard cotton hats. It requires partnering with a manufacturer who has an established supply chain for these advanced materials and the technical expertise to work with them.

You need to find a supplier who can demonstrate a clear understanding of the material's properties and can provide data to back up their claims. This involves asking for technical specifications, test reports, and certifications. Customization is also key, as the cap must be a core part of the team's official uniform.

What Certifications and Data Should You Request?

When vetting a supplier, ask for third-party test reports to verify their claims. This should include a thermal conductivity test (e.g., using the ASTM E1530 standard), a UPF test report (AATCC 183), and an antibacterial efficacy test (e.g., ISO 20743). A reputable manufacturer will have this data readily available. They should also be able to provide information on the source and quality of the graphene they use.

How Can the Caps Be Branded for an F1 Team?

Branding is paramount in F1. A graphene cap can be branded using the same high-quality techniques as any other premium cap. 3D embroidery for the main team logo on the front provides a bold, high-value look. Sponsor logos on the sides can be applied with flat embroidery or high-tech heat transfers. The key is to work with a manufacturer who can execute this branding with the precision and quality that a world-class F1 team demands. The cap must be a seamless part of the team's high-performance corporate identity.

Conclusion

In the world of Formula 1, where every thousandth of a second counts, the performance of the pit crew is just as critical as the performance of the car. Graphene baseball caps represent a significant leap forward in performance apparel, offering a tangible competitive advantage. By providing superior thermal regulation, permanent UV protection, and built-in antimicrobial properties, they help keep the crew cooler, safer, and more focused under the immense pressure of a race day. Sourcing this advanced headwear requires a partnership with a technically proficient manufacturer who understands the science and can deliver a product that meets the exacting standards of elite motorsport. It's the ultimate fusion of material science and functional design, built for the fastest team on Earth.

If you are a motorsport team, technical apparel brand, or corporate sponsor looking to leverage this cutting-edge technology, my team has the expertise to help you develop and produce graphene-infused performance headwear. Please contact our Business Director, Elaine, at elaine@fumaoclothing.com to explore the future of performance gear.