As a resident of a bustling city or a buyer for a health-conscious brand, you're acutely aware of a growing, invisible threat: air pollution. You see the daily air quality index, you read the headlines about the health effects of PM2.5, and you wonder how you can get a real-time, personal understanding of the air you're breathing as you move through your day.

The key to sourcing PM2.5 air quality-sensing smart caps is to partner with a specialized manufacturer that has proven expertise in integrating miniaturized environmental sensors and data connectivity into wearable apparel. This involves identifying suppliers who can embed a laser-based particle sensor, a processing unit, and a user interface (like an LED indicator or Bluetooth module) into a comfortable, stylish, and functional cap.

This technology might sound like it's straight out of a science fiction novel, but as a hat manufacturer who has been navigating the industry for over two decades, I can tell you it's the next frontier of functional headwear. At my company, Shanghai Fumao Clothing, we're moving beyond just fabric and thread into the realm of smart textiles. A smart cap that senses air quality isn't just a gadget; it's a personal environmental awareness tool that empowers the user to make healthier decisions. Let's explore how you can source this innovative technology.

Why Is a Smart Cap the Future of Personal Air Quality Monitoring?

You've probably seen phone apps that give you a city-wide air quality reading. While useful, this data is broad and generalized. The air quality on a busy, traffic-choked street can be drastically different from a quiet park just two blocks away. You need a personal, hyperlocal reading.

A PM2.5-sensing smart cap provides exactly that. It moves with you, sampling the air in your immediate vicinity and giving you real-time feedback. This transforms air quality data from an abstract number on a screen into an actionable, personal insight. It's the difference between knowing the weather report for the whole city and having a personal thermometer. This empowers users to make immediate decisions, like choosing a less polluted route for their run or putting on a mask when their cap alerts them to poor conditions.

How Does the PM2.5 Sensor Work?

The core of the smart cap is a miniaturized laser particle sensor. This tiny component, small enough to be embedded in the side of a cap, works by drawing in a small sample of air and passing it through a laser beam. When microscopic PM2.5 particles (particulate matter smaller than 2.5 micrometers) pass through the beam, they scatter the light. A photodetector measures this scattering and uses a sophisticated algorithm to calculate the concentration of these harmful particles in the air. This is the same core technology used in many high-end indoor air purifiers, now made small enough to be wearable. Sourcing a cap with a high-quality sensor from a reputable maker like Plantower or Sensirion is critical for accuracy.

How Does the Cap Display the Data?

Raw data isn't useful without a simple interface. The most common method is a multi-color LED indicator integrated into the cap's design. This provides an at-a-glance understanding of the current air quality, typically using the universal color code: green for good, yellow for moderate, red for unhealthy, and purple for very unhealthy. For more detailed data, the cap's processor can be equipped with a Bluetooth module. This allows it to connect to a smartphone app, where the user can see precise readings, track their exposure over time, and view a map of their journey with corresponding air quality data. This is a perfect example of the Internet of Things (IoT) being applied to personal wellness.

How Do You Find a Manufacturer for Such a Niche Product?

You won't find this technology at a standard apparel factory. Sourcing a PM2.5-sensing smart cap requires finding a highly specialized, tech-forward manufacturer that operates at the intersection of electronics, software, and textiles.

Your search should focus on manufacturers who explicitly advertise their capabilities in "smart textiles," "wearable technology," or "e-textiles." These are the partners who have invested in the multidisciplinary R&D teams necessary to integrate sensitive electronics into clothing. They understand the unique challenges, such as ensuring the device is durable, comfortable, and that the electronics can be safely removed for washing.

What Specific Capabilities Should You Look For?

When you contact a potential supplier, ask about their experience with sensor integration. Have they worked with air quality sensors before? Can they show you case studies or prototypes of other smart garments they have produced? Inquire about their electronics sourcing and certification process. They must be able to guarantee that the sensors and batteries are from reputable sources and have the necessary certifications (like CE, RoHS, FCC) for your target market. A vertically integrated partner like us at Shanghai Fumao Clothing who manages the entire process, from textile selection to final electronics assembly and testing, is a much safer bet than a factory that outsources the tech.

How Do You Verify the Accuracy of the Sensor?

This is a critical question. A smart cap is useless if its data is wrong. Ask the manufacturer how they calibrate and test the sensors. Do they test the final product against a reference-grade, professional air quality monitor? A serious manufacturer will have a clear quality assurance protocol for the electronic components. They should be able to provide you with a spec sheet for the sensor that details its accuracy, range, and margin of error. Don't be afraid to request this data or even ask for a sample to test against a known air quality monitor yourself.

What Are the Key Design and Construction Challenges?

Integrating a sensor into a hat is more complex than just sewing in a pocket. The design must be thoughtful, ensuring the final product is comfortable, aesthetically pleasing, and practical for everyday use.

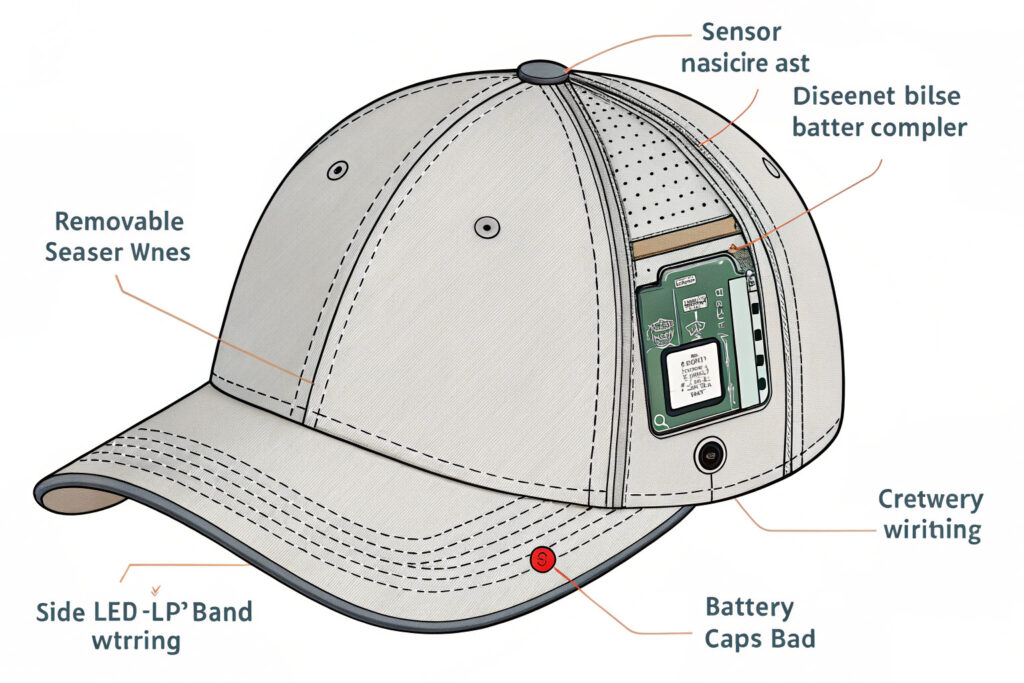

The primary challenges are sensor placement, component housing, and washability. The sensor needs access to ambient air without being overly exposed to the elements. The electronics need to be housed in a way that is comfortable for the wearer and doesn't create pressure points. And, most importantly, the user must be able to easily wash the hat without damaging the expensive technology inside.

Where Is the Best Place to Position the Sensor?

The ideal placement for the sensor module is on the side or the back of the cap's band. This position allows the sensor's intake vent to be exposed to the surrounding air while being somewhat protected by the cap's structure. It also keeps the electronic components away from the forehead, which is a sensitive area prone to sweating. The design must include a small, discreet opening covered by a fine mesh to allow air to enter the sensor while preventing larger dust particles or rain from getting in. This is a micro-engineering challenge that requires precision manufacturing.

How Do You Make the Hat Washable?

The only practical solution is to make the electronics fully removable. A well-designed smart cap will feature a custom-built, flexible pocket or a small plastic housing integrated into the sweatband. The entire smart module—containing the sensor, processor, and battery—can be easily slid out before washing. The cap itself can then be hand-washed or machine-washed according to the fabric's care instructions. This modular design is the cornerstone of creating a successful and long-lasting piece of wearable technology.

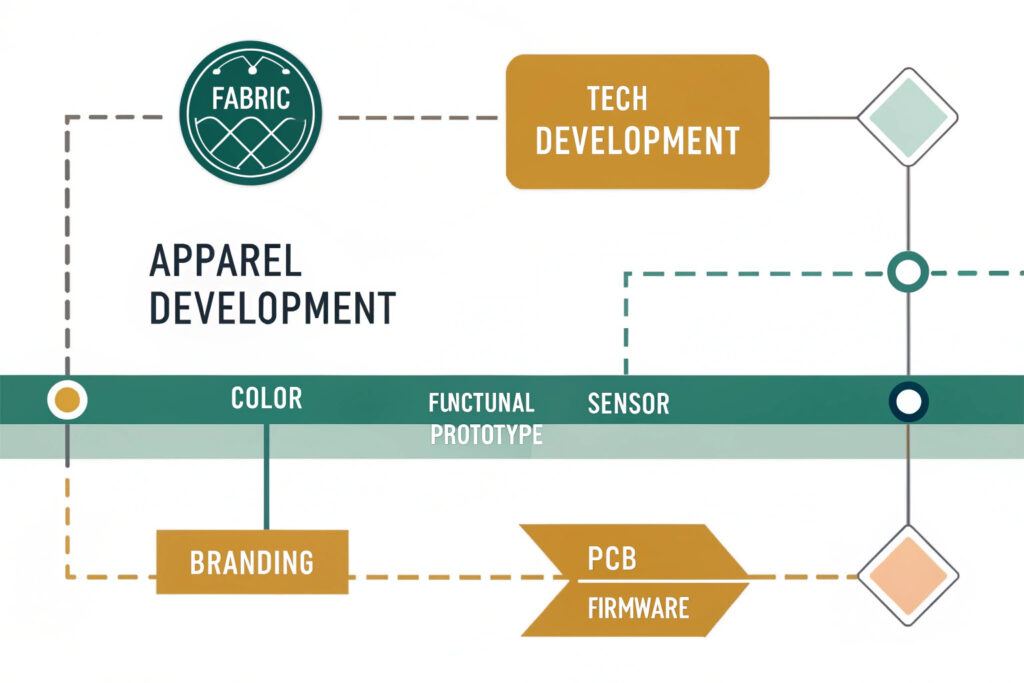

What Is the Sourcing and Customization Process Like?

Sourcing a smart cap is a more collaborative and technical process than ordering a standard hat. It involves stages of electronic development and software consideration alongside the usual apparel design process.

The process starts with defining the features you need. Do you want a simple LED indicator, or do you need Bluetooth connectivity and a companion app? Once the tech specs are defined, you move to the physical design. You can customize the cap's style (e.g., baseball cap, running cap), fabric, color, and branding, just like any other hat. The manufacturer will then create a prototype that integrates the electronics into your chosen design for you to test and approve.

How Much Customization Is Possible?

A surprising amount. While the core sensor module might be a standard component, almost everything else can be customized. You can choose the style of the cap—a sleek performance running cap is a great option for athletes, while a classic six-panel baseball cap works for everyday urban wear. You can select from a wide range of technical fabrics that are breathable and comfortable. And, of course, you can add your own branding through high-quality embroidery or modern techniques like high-frequency welding. You can even customize the behavior of the LED light or the features of the companion smartphone app.

What Is a Realistic Lead Time and Cost?

You should expect a longer lead time and higher cost than for a standard hat. The development of a functional prototype can take anywhere from 4 to 8 weeks, depending on the complexity. The unit cost will also be significantly higher due to the inclusion of the sensor, processor, and battery, likely falling in the range of a consumer electronics product rather than a simple apparel item. When requesting a quote, be sure you are getting a clear breakdown of the costs for the apparel component, the electronics, and any software development. This is not a cheap promotional item; it's a premium piece of health tech.

Conclusion

Sourcing a PM2.5 air quality-sensing smart cap is an exciting step into the future of functional, health-conscious apparel. It requires a shift in mindset from sourcing simple clothing to sourcing an integrated technology product. The key to success is finding a specialized manufacturing partner with proven expertise in both smart textiles and electronics integration. By focusing on the quality of the sensor, the intelligence of the design, and the reliability of the manufacturer, you can create a groundbreaking product that offers real value to your customers, empowering them with personal, real-time data about the air they breathe.

If you are a brand, innovator, or retailer ready to pioneer this new category of wearable technology, my team is at the forefront of this manufacturing evolution. We have the R&D capabilities and technical expertise to help you develop a custom smart cap. Please contact our Business Director, Elaine, at elaine@fumaoclothing.com to begin a conversation about your project.