You've sourced the perfect, eye-catching neon hats for the festival season. They look incredible, destined to be the star of countless social media posts. But then, after just one weekend in the sun, you get a customer complaint: the brilliant pink has faded to a dull salmon. This is a common and frustrating problem. Neon dyes are notoriously unstable, and nothing kills the vibrant festival vibe faster than a faded hat.

The key to preventing fading in neon-dyed festival hats lies in a multi-faceted approach that starts long before the hat ever sees the sun. It involves selecting the right fabric, using advanced dyeing techniques with high-quality, UV-resistant dyes, and applying a post-treatment UV-protective finish. For the end-user, simple care practices can then extend the life of the color.

As the owner of Shanghai Fumao Clothing, I've spent more than two decades tackling challenges just like this. The demand for vibrant, fluorescent colors is huge, but so is the expectation for quality and durability. For a buyer like you, understanding the science behind colorfastness is crucial for sourcing products that won't disappoint your customers. Let's break down how we create neon hats that stay bright from the opening act to the final encore.

Why Do Neon Colors Fade So Quickly?

Ever wondered why that electric green or hot pink seems to disappear in the sun? The problem isn't your eyes; it's the very nature of the dyes themselves. Neon, or fluorescent, colors are fundamentally less stable than conventional dyes. Their brilliance comes at a cost.

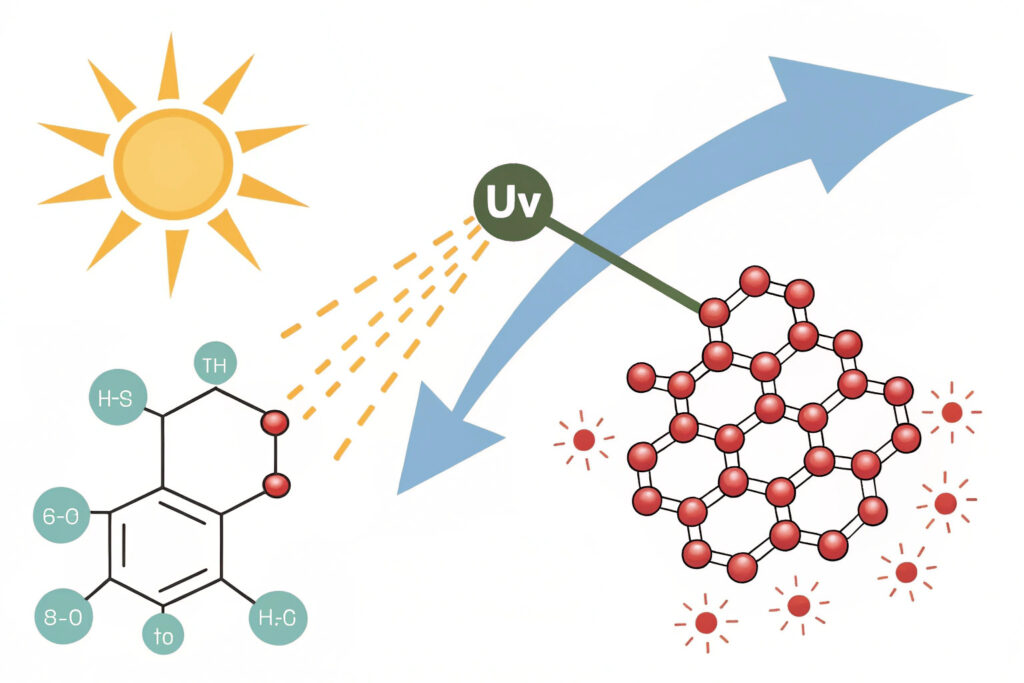

The vibrant glow of a neon color is created by special fluorescent molecules. These molecules absorb invisible ultraviolet (UV) light from the sun and re-emit it as visible light at a longer wavelength, which makes the color appear intensely bright to our eyes. However, this very process is destructive. Each time a dye molecule absorbs a photon of UV energy, it becomes "excited," and this high-energy state can cause the molecule's chemical bonds to break down. Over time, as more and more molecules are destroyed by UV radiation, the color literally fades away. This process is called photodegradation.

In our labs, we measure a dye's resistance to this process using a "lightfastness" scale. Neon dyes inherently have a lower lightfastness rating than standard dyes. This is a critical piece of data we analyze when developing products. It's not enough for a color to look good on day one; it has to last. This is why our approach focuses on advanced dyeing methods and protective finishes to fortify these fragile molecules against the onslaught of the sun.

Are some neon colors more prone to fading than others?

Yes, there is a difference. Generally, fluorescent pinks and yellows are known to be some of the most fugitive (prone to fading) colors. Blues and greens tend to be slightly more stable, but all fluorescent dyes are significantly less lightfast than their conventional counterparts. This is due to the specific chemical structures of the dye molecules. When sourcing, it's important to have this conversation with your manufacturer, as they can guide you toward the most durable options within the neon spectrum, a topic often discussed in textile chemistry resources like the AATCC (American Association of Textile Chemists and Colorists) blog.

Does chlorine from pools also cause fading?

Absolutely. Chlorine is a powerful oxidizing agent, which means it breaks down the chemical bonds in dye molecules through a chemical reaction, similar to how bleach works. For festival-goers who might also be attending pool parties, this is a double threat. A hat's resistance to chlorine is measured by a "colorfastness to chlorinated water" test. High-quality swimwear and festival gear must be engineered to resist both UV rays and chlorine. Reputable testing labs like SGS provide these specific tests to ensure products can withstand real-world conditions.

What Are the Best Dyeing Methods for Neons?

Getting a vibrant neon color to stick to a fabric and stay there is a science. You can't just use the same process as you would for a standard navy or black. To maximize longevity, you need to choose the right combination of fabric and dyeing technology.

The best approach for neon colors is to use synthetic fabrics like polyester or nylon. These materials allow for a process called disperse dyeing, which is done at high temperatures and pressures. This method forces the dye molecules to penetrate deep into the core of the fibers, creating a much stronger bond than a simple surface-level dye. This makes the color far more resistant to being washed away or broken down by UV light. Dyeing natural fibers like cotton with neons is much more challenging and often results in poorer lightfastness.

At our facility, we use state-of-the-art, high-pressure jet-dyeing machines specifically for our synthetic fabrics. We also invest in premium, high-energy disperse dyes that are engineered for better UV resistance. This is a more expensive and technical process, but it's the only way to achieve a neon color that has a fighting chance against the elements. It's a perfect example of how investing in the right production technology, like adding a UV-protective finish, directly translates to a higher quality, more durable final product for our clients.

What is the difference between pigment printing and dyeing?

Dyeing involves dissolving a colorant and having it absorbed into the fibers of the fabric, creating a chemical bond. Pigment printing, on the other hand, involves applying an insoluble colorant to the surface of the fabric and holding it there with a binding agent. While printing is great for detailed graphics, it's generally less durable than dyeing. The color sits on the surface, making it more susceptible to fading from abrasion and UV exposure. For solid neon colors, dyeing is the superior method for longevity, a fact supported by textile education platforms like Textile School.

Why is polyester a good choice for neon colors?

Polyester is a type of plastic, and its chemical structure is hydrophobic (it repels water). This makes it ideal for disperse dyes, which are also non-polar and work well with synthetic fibers. The high-temperature dyeing process allows the polyester fibers to swell, opening up pores for the dye to enter. As the fabric cools, the fibers constrict, trapping the dye molecules inside. This mechanical trapping results in excellent colorfastness. Major chemical companies like DuPont, who pioneered many synthetic fibers, have extensive documentation on the robust properties of polyester that make it suitable for performance apparel.

Can a Finish Be Applied to Boost UV Protection?

So, we've chosen the right fabric and used the best dyeing method. Can we do more? Yes. The final and most critical step in creating a fade-resistant neon hat is the application of a specialized finishing treatment. Think of it as sunscreen for your hat.

After the dyeing process, the fabric can be treated with a UV-absorbing or blocking finish. These are chemical compounds that are applied to the surface of the fabric. UV absorbers work by absorbing harmful UV radiation and converting it into harmless heat, sacrificing themselves to protect the dye molecules underneath. UV blockers, like titanium dioxide or zinc oxide (the same ingredients in mineral sunscreen), work by scattering or reflecting the UV rays away from the fabric altogether.

This is a standard part of our process for any high-performance or outdoor product at Shanghai Fumao Clothing. Applying a UV finish can significantly improve a fabric's lightfastness rating, often by several points. It adds a small cost to the production process, but the return on investment is enormous in terms of product longevity and customer satisfaction. It's the invisible technology that makes a visible difference and is a key part of our manufacturing best practices.

How is a UV finish applied to a hat?

The finish is typically applied to the fabric in a bath after dyeing, using a "pad-dry-cure" method. The fabric is passed through a trough containing the chemical solution, then squeezed through rollers (the "pad") to ensure even distribution. It's then dried and cured in an oven, which permanently bonds the finish to the fibers. This industrial process ensures the finish is durable and can withstand washing. For more details on textile finishing, resources from industry leaders like Huntsman Corporation often provide insights into these advanced chemical treatments.

Does a UV finish affect the feel of the fabric?

Modern UV finishing agents are designed to have a minimal impact on the "hand feel" of the fabric. When applied correctly, the finish should be virtually unnoticeable to the touch. The goal is to add performance without sacrificing comfort. However, a poorly applied or low-quality finish could potentially make a fabric feel slightly stiffer. This is why working with an experienced manufacturer who uses high-quality chemicals and processes is so important, a point often emphasized by quality assurance experts like those at Intertek.

What Are the Best Practices for Manufacturing Fade-Resistant Hats?

Creating a truly fade-resistant neon hat isn't about a single trick; it's about a commitment to quality at every single step of the manufacturing process. It's a system of best practices that separates a premium product from a disposable one.

First, it starts with a clear technical specification. As a buyer, you need to specify the required lightfastness rating for the product based on its intended use. For a festival hat, a rating of 4 or higher on the 1-5 blue wool scale is a good target for neons. Second, the manufacturer must use a controlled and documented process. This means using high-quality, UV-resistant dyes from reputable suppliers, precise temperature and pressure controls in the dyeing machines, and the correct application of a high-performance UV finish. Finally, rigorous quality control is essential. This involves testing the final fabric with a spectrophotometer to ensure color consistency and sending samples to a third-party lab to verify the lightfastness and colorfastness ratings.

This is the philosophy we live by at Shanghai Fumao Clothing. We don't just make hats; we engineer them. We work with our clients to define the performance standards and then build a production process to meet them. This commitment to quality is how you build a brand that customers trust to deliver products that last. It's about understanding the science behind why neons fade and proactively designing a product to overcome that challenge.

What is the "blue wool scale" for lightfastness?

The blue wool scale is the industry standard for measuring lightfastness. It consists of eight strips of blue wool, each dyed with a dye of different known lightfastness. The test fabric is exposed to a standardized light source alongside these strips. The lightfastness rating is determined by comparing which of the blue wool strips fades at the same rate as the test fabric. A rating of 1 is very poor, while a rating of 8 is excellent and doesn't fade. This method is standardized by organizations like the ISO (International Organization for Standardization).

How can a buyer verify a manufacturer's claims?

The best way is to request a third-party lab report for the specific fabric being used. Reputable manufacturers should be able to provide recent test reports for key metrics like lightfastness (e.g., AATCC 16.3) and colorfastness to washing. You can also request a "lab dip" (a small swatch of fabric dyed to your specified color) and conduct your own rudimentary tests, such as leaving it in a sunny window for a few weeks to observe any fading. For large orders, you can even commission your own tests through a lab like Bureau Veritas for ultimate peace of mind.

Conclusion

The vibrant allure of neon is undeniable, but its fleeting nature can be a major pitfall for any brand in the festival and fashion space. Preventing fading isn't magic; it's a deliberate and scientific process. It requires starting with the right synthetic materials, using advanced high-pressure dyeing methods, and sealing the deal with a powerful UV-protective finish. By understanding the science and partnering with a manufacturer who prioritizes quality control, you can offer your customers neon hats that stay brilliant long after the festival lights have dimmed.

This commitment to durability and performance is at the heart of what we do. We believe that even the most fun and fashionable products should be built to last. It's about delivering real value and building a brand reputation that shines as brightly as your products.

If you're looking to develop a line of high-quality, fade-resistant festival headwear, my team at Shanghai Fumao Clothing has the expertise and technology to make it happen. Let's create products that stand out and stand the test of time. You can start the conversation by reaching out to our Business Director, Elaine, at her email: elaine@fumaoclothing.com.