Have you ever wondered what it would be like to gaze at Earth from the quiet of space? With the dawn of space tourism, this dream is becoming a reality. But this new frontier brings unique challenges, especially when it comes to gear. You can't just wear a standard winter beanie in the extreme environment of space. You need something engineered for conditions that are literally out of this world.

The ideal headwear for space tourism is a cap insulated with aerogel. This remarkable material, originally developed by NASA, offers the highest insulating properties in the world for its weight. An aerogel-insulated cap can protect a space tourist from the extreme temperature swings experienced in orbit—from the intense solar radiation on one side to the freezing cold of deep space on the other—all while being incredibly lightweight and comfortable.

As the owner of Shanghai Fumao Clothing, a company that has spent over two decades pioneering high-performance textiles, the challenge of creating headwear for space is fascinating. It's the ultimate test of material science and functional design. While we may be rooted in Earth's textile industry, our vision is always on the next frontier. Let's explore why aerogel is the undisputed champion for insulating the next generation of space adventurers.

What Exactly Is Aerogel Insulation?

You've probably heard of fiberglass or foam for insulation, but aerogel is in a completely different league. It looks like solid smoke and feels almost weightless in your hand. So, what is this miracle material? It's a synthetic, porous, ultralight material derived from a gel, in which the liquid component of the gel has been replaced with a gas.

The result is a solid that is over 98% air. Its structure is a delicate, three-dimensional network of nanoparticles with incredibly small pores. This structure is the secret to its power: it's a super-insulator because it almost completely nullifies the three methods of heat transfer: conduction, convection, and radiation. The nano-sized pores trap air, preventing it from circulating and transferring heat (convection), while the solid structure itself is too sparse to be a good heat conductor.

At my company, we're constantly exploring cutting-edge materials. While we work with many high-performance fabrics, aerogel represents the pinnacle of insulation technology. Integrating it into a flexible, wearable item like a cap is a complex engineering challenge. It requires specialized techniques to create a composite fabric that maintains the aerogel's insulating properties without being rigid or brittle. This is the kind of innovation that pushes the entire apparel industry forward and is essential for creating gear for extreme environments like space.

How was aerogel invented?

Aerogel was first created by scientist Samuel Stephens Kistler in 1931. The story goes that he made a bet with a colleague that he could replace the liquid in a jar of jelly with gas without causing it to shrink. He succeeded by using a process called supercritical drying, which carefully removes the liquid from the gel's structure without causing it to collapse. This groundbreaking work, detailed in scientific journals like Nature at the time, laid the foundation for the development of the world's lightest solid material.

Is aerogel used in anything besides space applications?

Yes, absolutely. While it gained fame through its use by NASA for insulating rovers and spacesuits, aerogel's exceptional properties have found applications on Earth. It's used in high-performance outdoor gear like jackets and boots for extreme cold-weather expeditions. In construction, it's used as a super-insulating material for skylights and windows. Its applications are vast and growing, appearing anywhere that requires maximum thermal insulation with minimal weight and thickness.

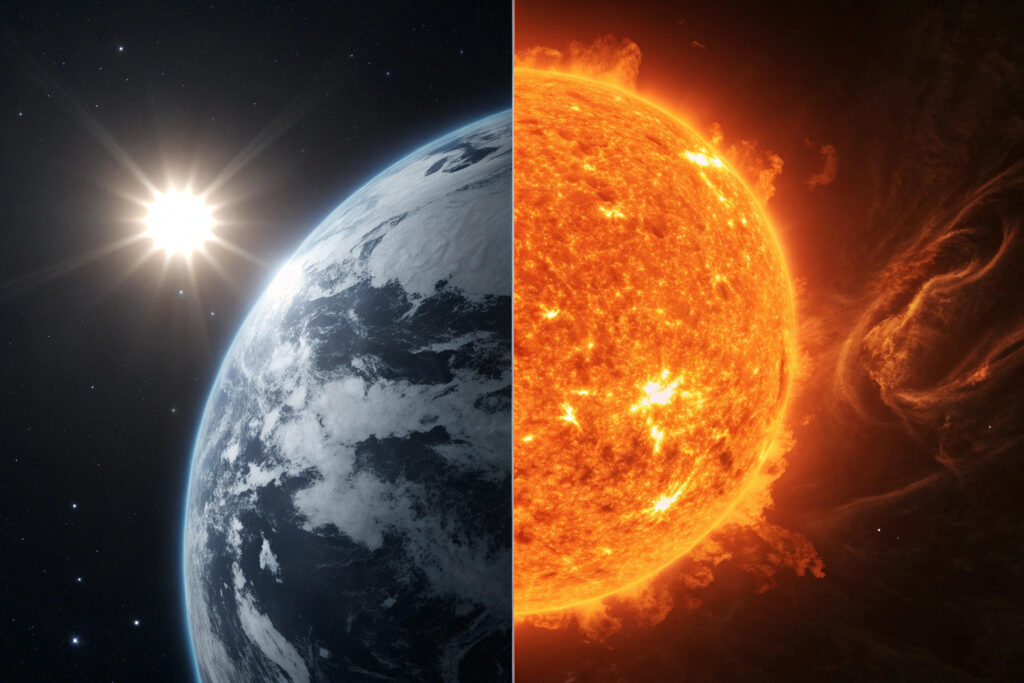

Why Is Extreme Temperature a Concern in Space?

When we think of space, we often just think of "cold." But the reality is far more complex. Space is a vacuum, which means there's no air to distribute heat. This creates a situation of extreme thermal contrasts that are unlike anything on Earth. It's a key reason why specialized gear, like aerogel caps, is not a luxury but a necessity.

An object in Earth's orbit, like a tourist spacecraft, is exposed to two extremes simultaneously. The side facing the sun can be heated by direct solar radiation to temperatures well over 250°F (120°C). At the same time, the side facing away from the sun, exposed to the cold void of deep space, can plummet to -250°F (-150°C). Even inside a spacecraft, temperature regulation is a critical challenge, and any time spent near a window or on a spacewalk (extravehicular activity) exposes a person to these massive temperature swings.

This is where the unique properties of aerogel truly shine. A conventional insulating material, like wool or down, works by trapping air. In the vacuum of space, that principle is less effective. Aerogel, however, provides a physical barrier that is incredibly effective at stopping heat transfer through both conduction and radiation. It can protect a wearer's head from both the intense heat of the sun and the bitter cold of the shade, providing a stable microclimate. This level of protection is paramount for ensuring the safety and comfort of space tourists.

How do spacecraft manage these temperature extremes?

Spacecraft use a sophisticated combination of systems for thermal control. This includes multi-layer insulation (MLI) blankets, which are like a high-tech version of a thermos, and active systems like fluid loops that circulate heated or cooled liquids to different parts of the vehicle. According to educational resources from space agencies like the European Space Agency (ESA), these systems are complex and mission-critical. Personal gear like an aerogel cap acts as a final, personal layer of this protective system.

Does the human body lose heat differently in a vacuum?

Yes. On Earth, we lose most of our body heat through convection (transfer to the air around us). In a vacuum, convection is impossible. Instead, the primary way the body loses heat is through thermal radiation. Every object with a temperature above absolute zero emits energy as infrared radiation. Without air to hold warmth in, your body will radiate its heat away into the cold of space much more rapidly. This is why materials that can block thermal radiation, like aerogel, are so crucial for personal gear in space.

What Makes Aerogel Caps Uniquely Suited for This Role?

We've established that space is an environment of thermal extremes and that aerogel is a super-insulator. Now, let's connect the dots. Why is an aerogel-insulated cap the perfect solution for a space tourist? It comes down to a unique combination of performance, weight, and comfort that no other material can match.

First is the unmatched thermal performance-to-weight ratio. The human head is one of the primary areas where the body loses heat. An aerogel cap can provide incredible insulation without the bulk or weight of traditional materials. A space tourist needs to be comfortable and mobile, not weighed down by heavy gear. Second, aerogel is breathable. Despite its incredible insulating properties, its porous structure allows water vapor (sweat) to escape, which is crucial for comfort during long periods of wear. Finally, it's about targeted protection. A cap focuses this advanced insulation exactly where it's needed most, protecting the head and brain from dangerous temperature fluctuations.

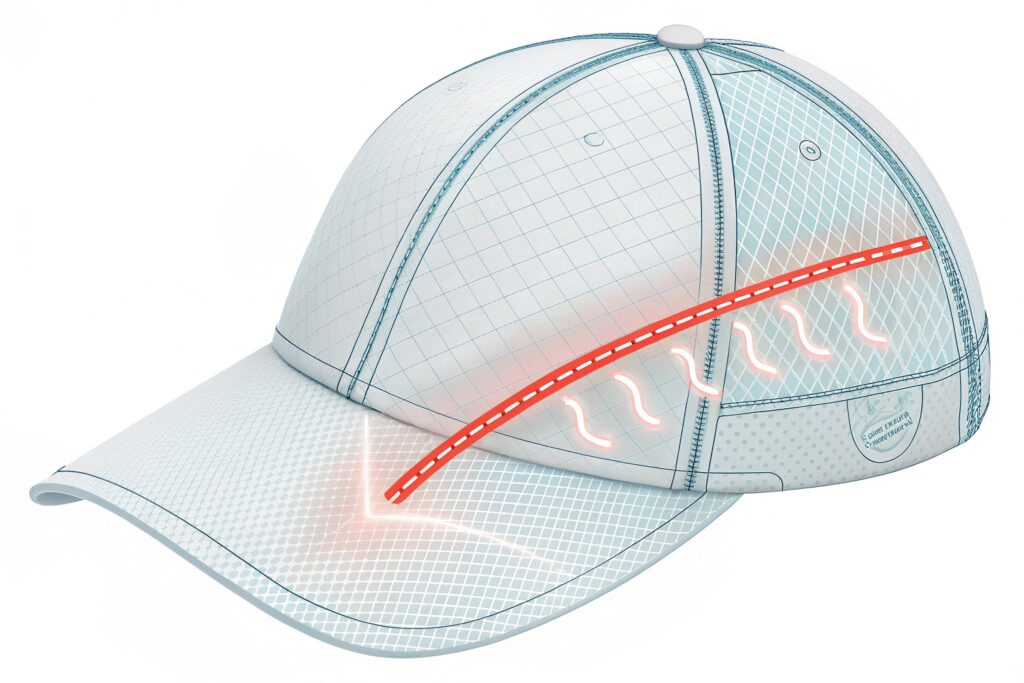

As a manufacturer, this is where design and engineering meet. At Shanghai Fumao Clothing, we would approach this by creating a composite fabric—a thin, flexible layer of aerogel sandwiched between soft, skin-friendly materials. The outer layer would be designed to reflect solar radiation, while the inner layer would prioritize comfort. This creates a single, lightweight piece of headwear that delivers a level of protection that was once reserved only for professional astronauts.

How is aerogel made flexible enough for a cap?

Pure, monolithic aerogel can be brittle. To make it wearable, manufacturers create aerogel "blankets" or composites. In this process, the aerogel is infused into a flexible, non-woven fiber batting. This creates a material that has the flexibility of fabric but retains the incredible insulating power of the aerogel. Companies like Aspen Aerogels are pioneers in this technology, creating flexible aerogel insulation that has been adopted by leading outdoor and technical apparel brands.

Is aerogel safe to wear against the skin?

Yes, when used in a composite fabric, aerogel is perfectly safe. The aerogel itself is contained within the fiber matrix and sandwiched between layers of fabric, so it doesn't come into direct contact with the skin. The materials used are typically silica-based (the main component of sand), which is non-toxic. All reputable manufacturers, including those who follow standards from organizations like ASTM International, ensure that the final textile product is hypoallergenic and safe for its intended use.

How Can a Manufacturer Produce Aerogel Headwear?

The idea of an aerogel-insulated cap is exciting, but how does it go from a concept to a real product? Manufacturing headwear with such an advanced material requires specialized expertise, equipment, and a deep understanding of material science. This is not something a typical garment factory can handle.

The process begins with sourcing the right material. A manufacturer must have a supply chain for aerogel composite blankets from a certified supplier. The next challenge is handling and cutting. Aerogel composites can be dusty and require special cutting tools (like ultrasonic cutters or water jets) and handling procedures to maintain a clean working environment and preserve the material's integrity. Then comes assembly. Sewing aerogel composites is different from sewing regular fabric. It requires specific needle types and sewing techniques to avoid compressing the aerogel, which would reduce its insulating properties.

This is where a partnership with an experienced R&D-focused manufacturer like Shanghai Fumao Clothing becomes crucial. We have the technical knowledge and the innovative mindset to tackle these challenges. We can develop prototypes, test performance, and create a scalable production process. For a brand looking to enter a new market like space tourism, a manufacturing partner doesn't just build the product; they provide the essential technical expertise to make the product possible in the first place.

What kind of quality control is needed for aerogel products?

Quality control for aerogel apparel is rigorous. It starts with verifying the authenticity and performance of the incoming aerogel material. During production, inspections are needed to ensure there is no excessive compression or damage to the insulation. Finally, the finished product might undergo thermal testing using infrared cameras to check for any cold spots or inconsistencies in the insulation. This level of QC ensures that every cap delivers the promised level of performance, a standard practice for high-performance gear reviewed by publications like OutdoorGearLab.

Can aerogel caps be customized with logos?

Yes, customization is definitely possible. Logos and other designs can be applied using methods that don't compromise the aerogel's function. Techniques like heat transfer or specialized printing that don't require high pressure are ideal. For a premium product like this, embroidery could also be used on the outer fabric layer, as long as the stitching doesn't penetrate and compress the core aerogel insulation. A skilled manufacturer can advise on the best customization methods, similar to how companies like 4imprint offer branding on a wide range of technical apparel.

Conclusion

As humanity stands on the brink of a new era in space travel, the gear we take with us must evolve. For the space tourist, protection from the unseen dangers of extreme temperatures is paramount. The aerogel-insulated cap represents the pinnacle of material science applied to personal gear—a solution that is incredibly lightweight, comfortable, and offers a level of thermal protection that was once the exclusive domain of space agencies. It's a perfect fusion of cutting-edge technology and practical design.

This is the kind of challenge that excites us. Pushing the boundaries of what's possible in headwear is what we've been doing for over 20 years. For any brand looking to pioneer products for this emerging and exciting market, the journey begins with a manufacturing partner who can turn visionary ideas into tangible, high-performance reality.

If you are ready to explore the future of technical headwear and create products for the next frontier, my team at Shanghai Fumao Clothing is equipped and eager to collaborate. Let's build the future together. Please reach out to our Business Director, Elaine, at her email: elaine@fumaoclothing.com to begin the conversation.