For a first responder, every second counts, and every piece of gear matters. But what about after the emergency? You've just come off a long, grueling shift, and your helmet liner is soaked with sweat and exposed to contaminants. The last thing you want is a complicated, time-consuming cleaning process. You're concerned about hygiene and the long-term integrity of your gear, but the thought of wrestling with complex clips and straps just to clean a liner is frustrating and often gets pushed aside.

Imagine a helmet liner that you can remove and replace in seconds. That's the life-saving simplicity of quick-detach systems. These innovative liners are designed specifically for first responders, allowing for immediate removal for cleaning, decontamination, or replacement. This means you can maintain impeccable hygiene, reduce your exposure to harmful substances, and get your helmet back in service faster. At Shanghai Fumao Clothing, we've applied our expertise in textile innovation to develop liner systems that prioritize both safety and practicality for those on the front lines.

This isn't just a matter of convenience; it's a critical issue of health and safety. The ability to easily clean gear is essential for reducing the risk of long-term health issues associated with occupational exposure. As a manufacturer deeply invested in functional textiles, I've seen firsthand how smart design can make a real-world difference. Let's explore where to find these essential pieces of equipment and what features you should be looking for.

Why Are Quick-Detach Liners a Non-Negotiable?

Think about the daily reality of your job. Your helmet is a constant companion, but it also becomes a breeding ground for bacteria and a sponge for hazardous materials encountered in the field. Traditional helmet liners are notoriously difficult to remove, often requiring tools or intricate maneuvering. This difficulty means liners are cleaned less frequently than they should be, leading to skin irritation, unpleasant odors, and, most critically, prolonged contact with carcinogens and other dangerous substances.

A quick-detach liner system completely changes the game. It transforms helmet hygiene from a chore into a simple, routine task. By enabling you to remove the liner in seconds, it encourages regular and thorough cleaning, directly addressing the health risks associated with contaminated gear. This isn't a luxury feature; it's an essential component of modern Personal Protective Equipment (PPE) that supports long-term health and well-being for first responders.

The ability to maintain clean gear without hassle is fundamental to occupational safety. It reduces daily irritants and mitigates cumulative exposure risks that can have life-altering consequences. Let's examine the specific health and operational benefits this system provides.

How do they improve hygiene and health?

First responders are exposed to a cocktail of dangerous substances, from soot and chemicals at a fire scene to biohazards at a medical emergency. These contaminants get absorbed by the helmet liner. The National Fire Protection Association (NFPA) has extensively documented the link between firefighter occupational exposure and increased cancer risk. Quick-detach liners are a crucial tool in this fight. By making it easy to remove the liner, you can implement a routine cleaning schedule, washing away these harmful particles after every shift. This drastically reduces the duration of skin contact with carcinogens and minimizes the risk of cross-contamination between your gear, vehicle, and home. It's a simple, proactive step that has a profound impact on long-term health.

What are the operational advantages?

Beyond health, quick-detach systems offer significant operational benefits. In situations requiring rapid decontamination, such as a hazmat incident, the ability to quickly strip a helmet of its soft goods is invaluable. It speeds up the entire decon process, allowing personnel to return to service faster. Furthermore, it simplifies maintenance and inspections. Liners can be easily removed to check for wear and tear or to inspect the helmet shell for damage, ensuring the integrity of the entire system. For departments managing a large inventory of helmets, this ease of maintenance saves countless hours of labor. It also allows for a "one helmet, multiple liners" system, where a responder can swap in a fresh, dry liner mid-shift, dramatically improving comfort and focus during extended incidents. This efficiency is a core principle of effective asset management in public safety.

Now that the "why" is clear, let's focus on where to source them.

Where Can You Source These Specialized Liners?

Knowing you need quick-detach liners is the first step, but finding a reliable supplier can be a challenge. A standard Google search might yield thousands of results for generic helmet pads, but these are not the specialized, durable systems required for first responder duties. You need a supplier who understands the stringent safety standards and harsh realities of your work environment. Sourcing from an unvetted manufacturer could result in a product that fails under pressure or doesn't meet regulatory requirements.

The most reliable sources for this specialized gear are established PPE manufacturers and their authorized distributors. These companies are experts in the field and design their products to meet or exceed standards like NFPA and NIJ (National Institute of Justice). You can find them by visiting their official websites, attending industry trade shows, or working with specialized safety equipment dealers who cater to police, fire, and EMS departments.

As a manufacturer, Shanghai Fumao Clothing, we often partner with these leading brands to co-develop and supply the advanced textile components for their liner systems. The key is to look for suppliers who are transparent about their materials, testing procedures, and certifications. Let's break down your primary sourcing channels.

Should you go directly to helmet manufacturers?

Yes, this is often the best starting point. Major helmet brands like MSA, Bullard, and Team Wendy design their helmets as integrated systems. Their quick-detach liners are specifically engineered to fit their helmet models perfectly, ensuring there is no compromise on safety or comfort. By purchasing directly from the Original Equipment Manufacturer (OEM) or their authorized dealers, you guarantee compatibility and maintain the helmet's original safety certification. Visiting the manufacturers' websites is the most direct way to see their latest offerings and find a list of official distributors in your region. This approach ensures you get a product that is tested and certified as a complete unit, which is a critical consideration for workplace safety compliance.

Are there specialized third-party suppliers?

Absolutely. Several innovative companies specialize exclusively in helmet liner and suspension system technology. Companies like 4D Tactical and Ops-Core (a brand of Gentex) focus on creating advanced, retrofittable liner kits that can upgrade existing helmets. These third-party suppliers often lead the market in comfort and impact-protection technology, offering features like advanced memory foam and enhanced ventilation. When considering a third-party upgrade, it is crucial to verify that the liner kit is tested and approved for use with your specific helmet model. Reputable suppliers will provide clear compatibility charts and testing data. These specialized companies are often found at major industry trade shows like the SHOT Show or the Fire Department Instructors Conference (FDIC), which are excellent venues for seeing the products firsthand.

With potential suppliers in mind, you need to know what features to look for.

What Key Features Should You Look For?

You've found a few potential suppliers, but their product descriptions are filled with technical jargon. How do you differentiate between a truly superior product and one that just has good marketing? Choosing the wrong liner can lead to poor comfort, inadequate performance, or a system that isn't as "quick-detach" as advertised. It's easy to get overwhelmed by options and end up with a product that doesn't meet the real-world demands of your job.

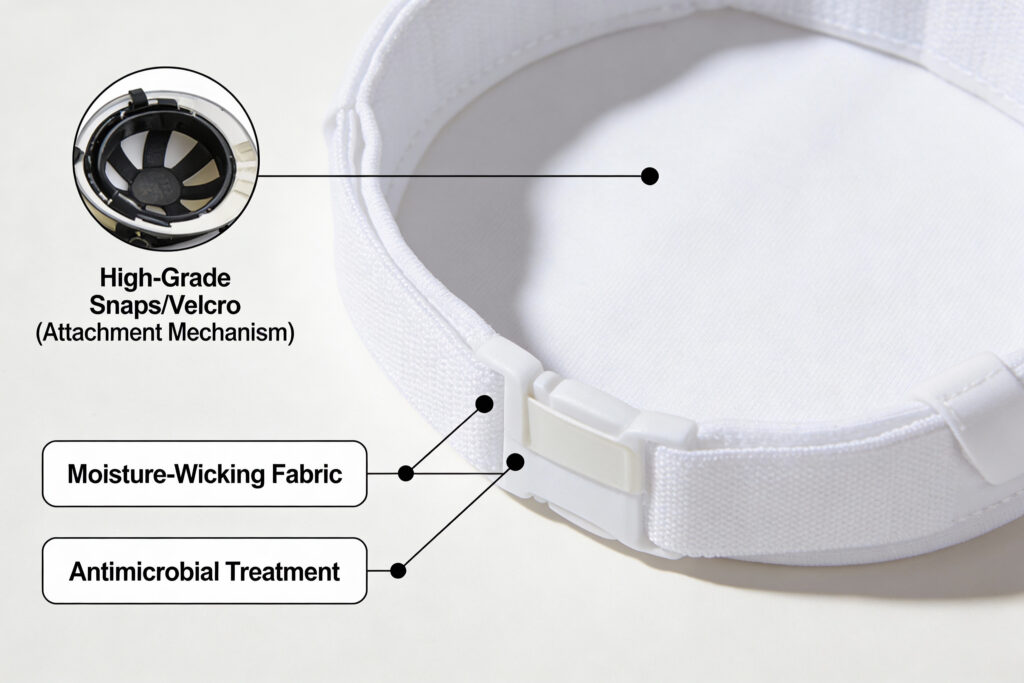

The most effective way to choose is to focus on three core areas: the attachment mechanism, the material technology, and the certifications. The attachment system is the heart of the "quick-detach" feature—it must be both secure and easy to operate. The fabric technology determines the liner's comfort and hygiene performance. And finally, certifications are your guarantee that the product meets established safety and quality standards.

By evaluating each liner against these key criteria, you can cut through the marketing noise and make an informed decision based on performance and safety. Let's take a closer look at what defines a top-tier liner.

How important is the attachment system?

It is critically important. The attachment mechanism must strike a perfect balance between being easy to release and being completely secure during use. Look for systems that use high-quality, industrial-grade components. This could include specially designed polymer clips, low-profile hook-and-loop (Velcro) systems rated for high-shear strength, or rust-resistant snaps. Avoid liners that use flimsy plastic parts or standard consumer-grade Velcro, as these can fail under stress or lose their effectiveness when dirty. The best way to evaluate this is to request a sample or watch a demonstration video. The detachment should be intuitive and possible even when wearing gloves. A well-designed system, like those using MIL-SPEC components, ensures reliability when it matters most.

What fabric technologies should you demand?

The fabric of the liner is in direct contact with your skin for hours, so its properties are crucial for comfort and hygiene. Modern liners should be made from multi-layered, high-performance textiles. Look for a moisture-wicking inner layer that pulls sweat away from your skin to keep you dry and prevent skin irritation. This is often a feature of advanced polyester fabrics. Additionally, an antimicrobial treatment is essential. These treatments, often using silver-ion technology, inhibit the growth of odor-causing bacteria and mold, keeping the liner fresher for longer between washes. At Shanghai Fumao Clothing, we integrate these technologies directly into the fabrics we produce for our clients in the safety sector, ensuring performance is woven right in.

Now that you know what to look for, let's talk about making the final purchase decision.

How Do You Make the Final Purchase Decision?

You've done your research, narrowed down your options, and you're ready to buy. But this is a significant investment, and the well-being of your team is on the line. There's a nagging fear that you might be overlooking something, or that the product that looks great on paper won't hold up in the field. Making the final call can be stressful, especially when you're responsible for the safety and comfort of others.

The best way to ensure you're making the right choice is to move from research to real-world evaluation. Don't just rely on spec sheets and sales pitches. Request samples and conduct a field test with a few of your most experienced team members. Their hands-on feedback is the most valuable data you can collect. A liner might seem great in an office, but how does it perform after a 12-hour shift? Is it still comfortable? Does the "quick-detach" feature still work when it's caked in mud?

This final step of practical evaluation removes the guesswork and builds confidence in your decision. It ensures that the product you choose is not just technically compliant, but also practically superior for the people who will depend on it every day.

Why is field testing essential?

Field testing is where theory meets reality. It allows you to assess the liner's performance in the actual conditions your team faces. Have a few members wear the sample liners on active duty for a week. Ask them to evaluate comfort, heat management, and how well the liner stays in place during strenuous activity. Have them test the detach and re-attach process multiple times, both when the helmet is clean and when it's dirty. This process will quickly reveal any weaknesses in the design that aren't apparent from a simple inspection. This type of user acceptance testing is standard practice for major procurement decisions and should be a non-negotiable part of your process.

How do you evaluate cost vs. long-term value?

It can be tempting to choose the cheapest option that meets the minimum requirements. However, this is often a false economy. A higher-quality liner, while more expensive upfront, typically offers a much better long-term value. Consider the liner's durability: a well-made product will withstand more wash cycles and last longer, reducing replacement costs over time. Also, factor in the health and comfort benefits. A liner that improves hygiene and comfort can lead to better morale, reduced sick days due to skin issues, and, most importantly, a healthier team in the long run. When presenting your decision to procurement, frame the purchase as an investment in occupational health and safety, not just an equipment expense. The long-term value of a healthier, more efficient team far outweighs the initial cost difference.

Conclusion

For first responders, a helmet is more than just protection; it's a critical piece of life-support equipment. The move towards quick-detach liners is a vital evolution in helmet design, directly addressing the crucial issues of hygiene, long-term health, and operational efficiency. By making it simple and fast to clean and maintain this essential gear, these systems empower first responders to take control of their health and safety. Sourcing these liners from reputable OEM manufacturers or specialized third-party suppliers, and rigorously evaluating them based on attachment systems, material technology, and real-world field testing, is the best way to ensure you are equipping your team with the best.

Making the right choice in PPE is a responsibility we take seriously. It requires thorough research, hands-on evaluation, and a focus on long-term value over short-term cost. The health and safety of your team are worth the investment.

If your organization is looking to develop a custom liner solution or needs a manufacturing partner who understands the demands of high-performance textiles, we are here to help. To discuss how we can support your team's needs, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's work together to create safer gear for those who protect us all.