Brands, teams, and organizations increasingly seek customizable hat solutions that allow quick identity changes without requiring multiple complete hats. Traditional embroidery and printing methods lack flexibility for frequent design changes, creating inventory challenges and limiting customization opportunities. The search for effective quick-change systems requires understanding both attachment mechanisms and patch manufacturing.

The most reliable quick-change Velcro hat patch systems come from manufacturers specializing in modular headwear who integrate hook-and-loop compatibility during initial hat construction rather than adding it as an afterthought.These suppliers understand the balance between secure attachment and easy interchangeability while offering comprehensive patch production services that ensure perfect compatibility between hats and patches.

This comprehensive guide explores supplier types, technical specifications, customization options, and quality considerations for sourcing effective Velcro hat patch systems that meet both functional and aesthetic requirements.

What types of suppliers specialize in Velcro patch systems?

Different supplier types offer varying approaches to Velcro patch systems, each with distinct advantages depending on your specific needs. Understanding these categories helps target the right manufacturing partners.

Specialized suppliers include modular headwear manufacturers, patch specialists with hat partnerships, full-service customization facilities, and technical gear producers with established quick-change systems for uniforms and team apparel.

Why choose integrated headwear manufacturers?

Integrated headwear manufacturers design Velcro compatibility directly into their hat patterns and construction processes. These suppliers typically offer complete system solutions including both the base hats and compatible patches, ensuring perfect alignment and performance. Their manufacturing approach incorporates the hook panel during crown construction, creating seamless integration that doesn't compromise the hat's structure or comfort. The best integrated manufacturers conduct rigorous testing to ensure the Velcro system maintains its holding power through repeated patch changes without damaging the hat fabric. This comprehensive approach prevents the compatibility issues that arise when sourcing hats and patches from separate suppliers.

What advantages do patch specialists offer?

Patch specialists focus exclusively on emblem production while maintaining partnerships with hat manufacturers. These suppliers offer extensive patch customization including intricate embroidery, woven details, PVC options, and printed patches—all designed for specific Velcro systems. Their expertise in patch construction ensures clean edges, proper backing adhesion, and optimal loop material selection for secure attachment. Many patch specialists maintain libraries of hat specifications from various manufacturers, allowing them to recommend the ideal patch size and shape for specific hat models. This specialized knowledge is particularly valuable for organizations needing patches for existing hat inventories from multiple manufacturers.

What technical specifications ensure reliable performance?

Not all Velcro systems perform equally in hat applications. Understanding technical specifications helps distinguish marketing claims from genuinely reliable quick-change systems that will withstand regular use.

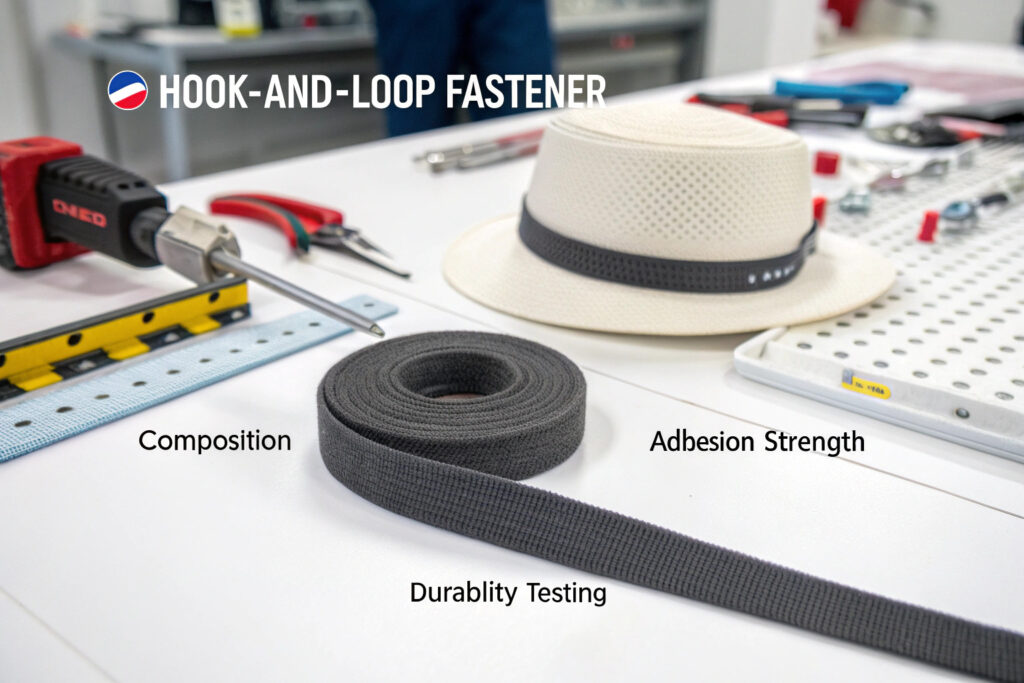

Critical technical specifications include hook-and-loop composition, adhesion strength metrics, durability testing results, and compatibility with different hat materials and constructions.

How does hook composition affect performance?

Hook composition determines both holding power and fabric compatibility. Industrial-grade nylon hooks provide superior holding strength (typically 18-24 ounces per square inch) and maintain their grip through thousands of engagements. The hook shape and distribution also matter—mushroom-shaped hooks offer gentler release while maintaining strong holding power, while standard hooks provide maximum security. For hat applications, the hook panel must be securely bonded to the crown material without creating uncomfortable stiffness or visible outlines. Premium manufacturers use ultrasonic welding or high-frequency bonding that integrates the hook panel seamlessly into the hat's structure rather than simply sewing or gluing it in place.

What adhesion strength is appropriate for different uses?

Adhesion strength requirements vary based on application. For frequent patch changes in retail or promotional environments, moderate adhesion (12-16 oz/in²) allows easy swapping without excessive force. For athletic or outdoor use where patches must withstand wind and activity, stronger adhesion (18-24 oz/in²) prevents accidental detachment. The most versatile systems balance secure holding with reasonable removal effort, typically in the 16-20 oz/in² range. Reputable suppliers provide adhesion test data specific to their hat materials rather than generic Velcro specifications, as backing material and application method significantly impact real-world performance.

What customization options work with Velcro systems?

Velcro patch systems offer extensive customization possibilities, but certain approaches work better than others for specific applications. Understanding these options ensures both aesthetic appeal and functional performance.

Effective customization includes patch size and shape variations, attachment location options, specialized materials for different environments, and design techniques that maintain clarity and durability.

Which patch sizes and shapes work best?

Patch size and shape should complement the hat's proportions while providing sufficient surface area for secure attachment. The most effective patch dimensions typically range from 2-4 inches in width for front panel applications, with slightly smaller sizes for side placements. Standard shapes (circles, ovals, rectangles) provide maximum hook contact and prevent corner lifting, while custom shapes require strategic hook panel placement to ensure all edges maintain contact. For curved crown surfaces, slightly smaller patches often work better as they conform more easily to the hat's shape. The best suppliers create digital mockups showing how different patch sizes and shapes will appear on specific hat models before production begins.

How do attachment locations affect usability?

Attachment location impacts both aesthetics and functionality. Front panel placement offers maximum visibility but requires precise centering. Side placements provide stylistic flexibility but may interfere with structured crown seams. Some systems incorporate multiple attachment points—front and sides—allowing multiple patches or rotational positioning. For performance applications, placement must consider sightlines and potential interference with other gear. The most thoughtful manufacturers design the hook panel placement during pattern development rather than adding it to existing designs, ensuring optimal positioning that doesn't compromise the hat's structure or comfort.

How to evaluate supplier quality and reliability?

Supplier evaluation ensures consistent quality across hat and patch production. The right partners demonstrate specific capabilities that predict successful long-term performance of Velcro patch systems.

Key evaluation factors include manufacturing consistency, material quality verification, customization capabilities, and testing protocols that ensure system durability through repeated use.

What manufacturing consistency indicates quality?

Manufacturing consistency ensures that hook panels are identically positioned across production runs, allowing patches to interchange seamlessly between hats. Quality manufacturers implement precise placement jigs and automated systems that position hook panels within 1-2mm tolerance. They maintain detailed specifications for each hat model, including exact hook panel dimensions, placement measurements, and adhesive application parameters. During facility evaluations, observe their quality control processes for hook panel installation—the best suppliers conduct 100% inspection of this critical component rather than random sampling. This consistency is particularly important for organizations requiring uniform appearance across team members or retail inventory.

How do testing protocols predict long-term performance?

Comprehensive testing protocols simulate real-world use conditions to predict system longevity. Reputable suppliers conduct engagement cycle testing that measures holding power after hundreds of attachment/detachment cycles, UV exposure testing to evaluate adhesive degradation, and wash testing to ensure the system withstands cleaning. For hat applications, flexibility testing is particularly important—the system must maintain adhesion when the crown flexes during wear. The best suppliers provide test reports specific to their hat materials and construction methods, demonstrating understanding that Velcro performance varies significantly based on the substrate material and application technique.

Conclusion

Sourcing effective quick-change Velcro hat patch systems requires partnering with manufacturers who understand both the technical requirements of hook-and-loop systems and the practical considerations of hat design and usage. The most successful implementations balance secure attachment with easy interchangeability while maintaining the hat's comfort, appearance, and durability.

At Global-Caps, we've integrated Velcro compatibility into our manufacturing process, designing hats specifically for patch systems rather than adapting existing designs. Our technical expertise ensures optimal hook panel integration, while our patch production capabilities guarantee perfect compatibility between components. If you're looking for a comprehensive quick-change hat solution that combines reliable performance with extensive customization options, contact our Business Director Elaine at elaine@fumaoclothing.com. Let us help you implement a flexible hat system that adapts to your changing needs without compromising quality or appearance.